The History of the Baldwin Locomotive

Works

Excerpts (Chapters 1 and 2)

from Fred

Westing’s, The Locomotives that Baldwin Built.

The material was originally produced in an earlier

history largely written by Paul T. Warner and is

widely available in the many catalogs of Baldwin

engines. These excerpts cover the period through

1835 when Hopkin Thomas was at Baldwin.

[J. McV., Dec., 2007]

CHAPTER I.

THE FIRST BALDWIN LOCOMOTIVE

THE

Baldwin Locomotive Works dates its origin from the inception of steam railroads

in America. Called into existence by the early requirements of the railroad

interests of the country, it has grown With their growth and kept pace with

their progress. It has reflected in its career the successive stages of

American railroad practice, and has itself contributed largely to the

development of the locomotive as it exists today. A history of The Baldwin

Locomotive Works, therefore, is in a great measure, a record of the progress of

locomotive engineering in this country, and as such cannot fail to be of

interest to those who are concerned in this important element of our material

progress.

At

the present date (1923?), the Works occupy 19.6 acres in the heart of

Philadelphia and 616 acres at Eddystone, on the Delaware River, twelve miles

below the city. The offices and principal machine shops are situated in the

rectangle bounded on the north by Spring Garden Street, on the east by Broad

Street, on the south by the Philadelphia and Reading Railway Subway and on the

West by Nineteenth Street. There are also shops located oil the line of the

Philadelphia and Reading Railway at Twenty-sixth to Twenty-ninth Streets.

MATTHIAS

W. BALDWIN, the founder of the establishment, learned the trade of a jeweler,

and entered the service of Fletcher & Gardiner, Jewelers and Silversmiths,

Philadelphia, in 1817. Two years later he opened a small shop, in the same line

of business, on his own account. The demand for articles of this character

falling off, however, he formed a partnership in 1825, with David Mason, a

machinist, in the manufacture of bookbinders' tools and cylinders for calico

printing. Their shop was in "Coffee-House Alley," which ran north

from Walnut Street, above Fourth. They afterward removed to Minor Street, below

Sixth. The business was so successful that steam power became necessary in

carrying on their manufacture, and an engine was bought for the purpose. This

proving unsatisfactory, Mr. Baldwin decided to design and construct one which

should be specially adapted to the requirements of his shop. One of these

requirements was that it should occupy the least possible space, and this was

met by the construction of an upright engine on a novel and ingenious plan. On

a bed-plate about five feet square an upright cylinder was placed; the piston

rod connected to a cross-bar having two legs turned downward, and sliding in

grooves on the sides of the cylinder, which thus formed the guides. To the

sides of these legs, at their lower ends, was connected by pivots an U-shaped

frame, prolonged at the arch into a single rod, which took hold of the crank of

a flywheel carried by upright standards on the bed-plate. It will be seen that

the length of the ordinary separate guide-bars was thus saved, and the whole

engine was brought within the smallest possible compass. The design of the

machine was not only unique, but its workmanship was so excellent, and its

efficiency so great, as readily to procure for Mr. Baldwin orders for

additional stationary engines. His attention was thus turned to steam

engineering, and the way was prepared for his grappling with the problem of the

locomotive when the time should arrive.

This

original stationary engine, constructed prior to 1830, is still in good order

and carefully preserved at the Works. It has successively supplied the power in

six different departments as they have been opened, from time to time, in the

growth of the business.

The

manufacture of stationary steam engines thus took a prominent place in the

establishment, and Mr. Mason shortly afterward withdrew from the partnership.

In

1829-30 the use of steam as a motive power oil railroads had begun to engage

the attention of American engineers. A few locomotives had been imported from

England, and one (which, however, was not successful) had been constructed at

the West Point Foundry, in New York City. To gratify the public interest in the

new motor, Mr. Franklin Peale, then proprietor of the Philadelphia Museum,

applied to Mr. Baldwin to construct a miniature locomotive for exhibition in

his establishment. With the aid only of the imperfect published descriptions

and sketches of the locomotives which had taken part in the Rainhill

competition in England, Mr. Baldwin undertook the work, and on the 25th of

April, 1831, the miniature locomotive was put in motion oil a circular track

made of pine boards covered with hoop iron, in the rooms of the Museum. Two

small cars, containing seats for four passengers, were attached to it, and the

novel spectacle attracted crowds of admiring spectators. Both anthracite and

pine-knot coal were used as fuel, and the exhaust steam was discharged into the

chimney, thus utilizing it to increase the draught.

The

success of the model was such that, in the same year, Mr. Baldwin received an

order for a locomotive from the Philadelphia, Germantown and Norristown

Railroad Company, whose line of six miles to Germantown was operated by horse power. The Camden

and Amboy Railroad Company had shortly before imported a locomotive from

England, which was stored in a shed at Bordentown. It had not yet been put

together; but Mr. Baldwin, in company with his friend Mr. Peale, visited the

spot, inspected the detached parts, and made a few memoranda of some of its

principal dimensions. Guided by these figures and his experience with the Peale

model, Mr. Baldwin commenced the task. The difficulties to be overcome in

filling the order can hardly be appreciated at this day. There were few

mechanics competent to do any part of the work on a locomotive. Suitable tools

were with difficulty obtainable. Cylinders were bored by a chisel fixed in a

block of wood and turned by hand. Blacksmiths able to weld a bar of iron

exceeding one and one-quarter inches in thickness were few, or not to be had.

It was necessary for Mr. Baldwin to do much of the work with his own hands, to

educate the workmen who assisted him, and to improvise tools for the various

processes.

The

work was prosecuted, nevertheless, under all these difficulties, and the

locomotive was fully completed, christened "Old Ironsides," and tried

on the road, November 23, 1832. The circumstances of the trial are fully

preserved, and are given, farther on, in the extracts from the journals of the

day. Despite some imperfections, naturally occurring in a first effort, and

afterward to a great extent remedied, the engine was, for that early day, a

marked and gratifying success. It was put at once into service, as appears from

the Company's advertisement three days after the trial, and did duty on the

Germantown road and others for over a score of years.

The Old Ironsides, 1832

The

"Ironsides" was a four-wheeled engine, modeled essentially on the

English practice of that day, as shown in the "Planet" class, and

weighed, in running order, something over five tons. The rear or driving wheels

were 54 inches in diameter on a crank axle placed in front of the firebox. The

cranks were 39 inches from center to center. The front wheels, which were

simply carrying wheels, were 45 inches in diameter, on an axle placed just back

of the cylinders. The cylinders were 9-1/2 inches in diameter by 18 inches

stroke, and were attached horizontally to the outside of the smokebox, which

was D-shaped, with the sides receding inwardly, so as to bring the center line

of each cylinder in line with the center of the crank. The wheels were made

with heavy cast-iron hubs, wooden spokes and rims, and wrought-iron tires. The

frame was of wood, placed outside the wheels. The boiler was 30 inches in

diameter, and contained 72 copper tubes, 1-1/2 inches in diameter and seven

feet long. The tender was a four-wheeled platform, with wooden sides and back,

carrying an iron box for a water tank, enclosed in a wooden casing, and with a

space for fuel in front. The engine had no cab. The valve motion was at first

given by a single loose eccentric for each cylinder, placed on the axle between

the crank and the hub of the wheel. On the inside of the eccentric was a

half-circular slot, running half way around. A stop was fastened to the axle at

the arm of the crank, terminating in a pin which projected into the slot. The

engine was reversed by changing the position of the eccentric on the axle by a

lever operated from the footboard. This form of valve motion was, however,

shortly afterward changed, and a single fixed eccentric for each cylinder

substituted. The rock shafts, which were under the footboard, had arms above

and below, and the eccentric straps had each a forked rod,with a hook, or an

upper and lower latch or pin, at their extremities, to engage with the upper or

lower arm of the rock shaft. The eccentric rods were raised or lowered by a

double treadle, so as to connect with the upper or lower arm of the rock shaft,

according as forward or backward gear was desired. A peculiarity in the exhaust

of the "Ironsides " was that there was only a single straight pipe

running across from one cylinder to the other, with an opening in the upper

side of the pipe, midway between the cylinders, to which was attached at right

angles the perpendicular pipe into the chimney. The cylinders, therefore,

exhausted against each other; and it was found, after the engine had been put

in use, that this was a serious objection. This defect was afterward remedied

by turning each exhaust pipe upward into the chimney substantially as it is now

done. The steam joints were made with canvas and red lead, as was the practice

in English locomotives, and in consequence much trouble was caused, from time

to time, by leaking.

The

price of the engine was to have been $4000, but some difficulty was found in

procuring a settlement. The Company claimed that the engine did not perform

according to contract; and objection was also made to some of the defects

alluded to. After these had been corrected as far as possible, however, Mr.

Baldwin finally succeeded in effecting a compromise settlement, and received

from the Company $3500 for the machine.

The

results of the trial and the impression produced by it on the public mind may

be gathered from the following extracts from the newspapers of the day:

The

United States Gazette,

of November 24, 1832, remarked:

"A most gratifying experiment was made

yesterday afternoon on the Philadelphia, Germantown and Norristown Railroad.

The beautiful locomotive engine and tender, built by Mr. Baldwin, of this city,

whose reputation as an ingenious machinist is well known, were for the first

time placed on the road. The engine traveled about six miles, working with

perfect accuracy and case in all its parts, and with great velocity."

The

Chronicle of the same

date noticed the trial more at length, as follows:

" It gives us pleasure to state that the

locomotive engine built by our townsman, M. W. Baldwin, has proved highly

successful. In the presence of several gentlemen of science and information on

such subjects, the engine was yesterday placed upon the road for the first

time, All her parts had been previously highly finished and fitted together in

Mr. Baldwin’s factory. She was taken apart on Tuesday, and removed to the

Company's depot and yesterday morning she was completely together, ready for

travel. After the regular passenger cars had arrived front Germantown in the

afternoon, the tracks being clear, preparation was made for her starting. The

placing fire in the furnace and raising steam occupied 20 minutes. The engine

(with her tender) moved front the depot in beautiful style, working with great

ease and uniformity. She proceeded about half a mile beyond the Union Tavern at

the township line, and returned immediately, a distance of six miles, at a

speed of about 28 miles to the hour, her speed having been slackened at all the

road crossings, and it being after dark, but a portion of her power was used.

It is needless to say that the spectators were delighted. From this experiment

there is every reason to believe this engine will draw 30 tons gross, at all

average speed of 40 miles an hour, on a level road. The principal superiority

of the engine over any of the English ones known consists in the light weight

which is but between four and five tons - her small bulk, and the simplicity of

her working machinery. We rejoice at the result of this experiment, as it

conclusively shows that Philadelphia, always famous for the skill of her

mechanics, is enabled to produce steam engines for railroads combining so many

superior qualities as to warrant, the belief that her mechanics will hereafter

supply nearly all the public works of this description in the country.”

On

subsequent trials, the " Ironsides" attained it speed of 30 miles per

hour, with its usual train attached. So great were the wonder and curiosity

which attached to such a prodigy, that people flocked to see the marvel, and

eagerly bought the privilege of riding after the strange monster. The officers

of the road were not slow to avail themselves of the public interest to

increase their passenger receipts, and the advertisement on page 14, from Poulson's

American Daily Advertiser,

of November 26, 1832, will show that as, yet they regarded the new machine

rather as it curiosity and a bait to allure travel than as a practical

every-day servant.

This

announcement did not mean that in wet weather horses would be attached to the

locomotive to aid it in drawing the train, but that the usual horse cars would

be employed in making the trips upon the road without the engine.

Upon

making the first trip to Germantown with a passenger train with the "

Ironsides," one of the drivers slipped upon tile axle, causing the wheels

to track less than the gauge of the road and drop in between the rails. It was

also discovered that the valve arrangement of the pumps was defective, and they

failed to supply the boiler with water. The shifting of the driving wheel upon

the axle fastened the eccentric, so that it would not operate in backward

motion. These mishaps caused delay, and prevented the engine from reaching its

destination, to the great disappointment of all concerned. They were corrected

in a few days, and the machine was used in experimenting upon its efficiency,

making occasional trips with trains to Germantown. The road had an ascending

grade, nearly uniform, of 32 feet per mile, and for the last half mile of 45

feet per mile, and it was found that the engine was too light for the business

of the road upon these grades.

Such

was Mr. Baldwin's first locomotive; and it is related of him that his

discouragement at the difficulties which he had undergone in building it, and

in finally procuring a settlement for it, was such that he remarked to one of

his friends, with much decision, "That is our last locomotive."

It

was some time before lie received an order for another, but meanwhile the

subject had become singularly fascinating to him, and occupied his mind so

fully that he was eager to work out his new ideas in a tangible form.

CHAPTER II.

EARLY IMPROVEMENTS IN THE LOCOMOTIVE

Shortly

after the "Ironsides" had been placed on the Germantown road, Mr. E.

L. Miller, of Charleston, S. C., came to Philadelphia and made a careful

examination of the machine. Mr. Miller had, in 1830, contracted to furnish a

locomotive to the Charleston and Hamburg Railroad Company, and accordingly the

engine "Best Friend" had been built under his direction at the West

Point Foundry, New York.

The “Best Friend” of

Charleston

After

inspecting the "Ironsides," he suggested to Mr. Baldwin to visit the

Mohawk and Hudson Railroad, and examine in English locomotive which had been

placed on that road in July, 1831, by Messrs. Robert Stephenson & Co., of

Newcastle, England.

Stephenson’s “Planet”

It

was originally a four-wheeled engine of the "Planet" type, with

horizontal cylinders and crank axle. The front wheels of this engine were

removed about a year after the machine was put at work, and a four-wheeled

swiveling or "bogie" truck substituted. The result of Mr. Baldwin's

investigations was the adoption of this design, but with some important

improvements. Among these was the "half-crank," which he devised on

his return from this trip, and which he patented September 10, 1834. In this

form of crank, the outer arm is omitted, and the wrist is fixed in a spoke of

the wheel. In other words, the wheel itself formed one arm of tile crank. The

result sought and gained was that the cranks were strengthened, and, being at

the extremities of the axle, the boiler could be made larger in diameter and

placed lower. The driving axle could also be placed back of the firebox; the connecting

rods passing by the sides of the firebox and taking hold inside of the wheels.

']'his arrangement of the crank also involved the placing of the cylinders

outside the smokebox, as was done on the “Ironsides”

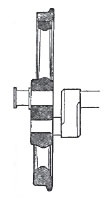

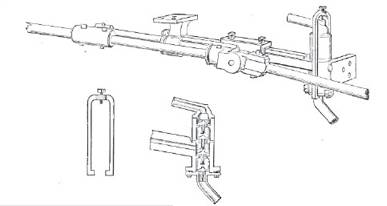

The Half-Crank

By

the time the order for the second locomotive was received, Mr. Baldwin had

matured this device and was prepared to embody it in practical form. The order

came from Mr. E. L. Miller, in behalf of the Charleston and Hamburg Railroad

Company, and the engine bore his name, and was completed February 18, 1834. It

was on six wheels; one pair being drivers, 54 inches in diameter, with

half-crank axle placed back of the firebox as above described, and the four

front wheels combined in a swiveling truck. The driving wheels, it should be

observed, were cast in solid bell metal. The combined wood and iron wheels used

on the "Ironsides" had proved objectionable, and Mr. Baldwin, in his

endeavors to find a satisfactory substitute, had recourse to brass. June 29,

1833, he took out a patent for a cast brass wheel, his idea being that by

varying the hardness of the metal the adhesion of the drivers on the rails

could be increased or diminished at will. The brass wheels on the

"Miller," however, soon wore out, and the experiment with this metal

was not repeated. The "E. L. Miller" had cylinders ten inches in

diameter; stroke of piston, sixteen inches; and weighed, with water in the

boiler, seven tons eight hundred-weight. The boiler had a high dome over the

firebox; and this form of construction, it may be noted, was followed, with a

few exceptions, for many years.

The

valve motion was given by a single fixed eccentric for each cylinder. Each

eccentric strap had two arms attached to it, one above and the other below,

and, as the driving axle was back of the firebox, these arms were prolonged

backward under the footboard, with a hook on the inner side of the end of each.

The rock shaft had arms above and below its axis, and the hooks of the two rods

of each eccentric were moved by hand levers so as to engage with either arm,

thus producing backward or forward gear. This form of single eccentric,

peculiar to Mr. Baldwin, was in the interest of simplicity in the working

parts, and was adhered to for some years. It gave rise to an animated

controversy among mechanics as to whether, with its use, it was possible to get

a lead on the valve in both directions. Many maintained that this was

impracticable; but Mr. Baldwin demonstrated by actual experience that the

reverse was the case.

Meanwhile

the Commonwealth of Pennsylvania had given Mr. Baldwin an order for a

locomotive for the State Road, as it was then called, from Philadelphia to

Columbia, which, up to that time, had been worked by horses. This engine,

called the "Lancaster," was completed in June, 1834. It was similar

to the "Miller," and weighed 17,000 pounds. After it was placed in

service, the records show that it hauled at one time nineteen loaded burden

cars over the highest grades between Philadelphia and Columbia. This was

characterized at that time by the officers of the road as an

"unprecedented performance." The success of the machine on its trial

trips was such that the Legislature decided to adopt steam power for working

the road, and Mr. Baldwin received orders for several additional locomotives.

Two others were accordingly delivered to the State in September and November

respectively of that year, and one was also built and delivered to the

Philadelphia and Trenton Railroad Company during the same season. This latter

engine, which was put in service October 21, 1834, averaged 21,000 miles per

year to September 15, 1840.

Five

locomotives were thus completed in 1834, and the new business was fairly under

way. The building in Lodge Alley, to which Mr. Baldwin had removed from Minor

Street, and where these engines were constructed, began to be found too

contracted, and another removal was decided upon. A location on Broad and

Hamilton Streets (the site, in part, of the present works) was selected, and a

three-story L-shaped brick building, fronting on both streets, erected. This

was completed and the business removed to it during the following year (1835).

Mr. Baldwin's stationary engine, described on page 8, was placed in service in

the new shop by Mr. Andrew C. Vauclain, father of Mr. Samuel M. Vauclain, who

is now President of the Company. The original building was partially destroyed

by fire in 1884, and was replaced by a four-story brick structure.

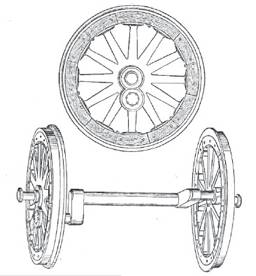

Baldwin Locomotive, 1834

These

early locomotives, built in 1834, were the types of Mr. Baldwin's practice for

some years. All, or nearly all of them, embraced several important devices,

which were the results of his study and experiments up to that time. The

devices referred to were patented September 10, 1834, and the same patent

covered the following four inventions, viz.:

1.

The half-crank, and method of attaching it to the driving wheel. (This has

already been described.)

2.

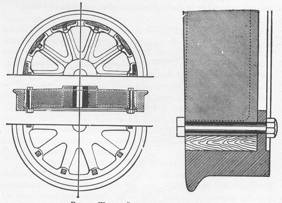

A new mode of constructing the wheels of locomotive engines and cars. In this

the hub and spokes were of cast iron, cast together. The spokes were cast

without a rim, and terminated in segment flanges, each spoke having a separate

flange disconnected from its neighbors. By this means, it was claimed, the

injurious effect of the unequal expansion of tile materials composing the

wheels was lessened or altogether prevented. The flanges bore against wooden

felloes, made in two thicknesses, and put together so as to break joints.

Tenons or pins projected from the flanges into openings made in the wooden

felloes, to keep them in place. Around the whole the tire was passed and

secured by bolts.

Baldwin Compound Wood

and Iron Wheels, 1834

3.

A new mode of forming the joints of steam and other tubes. This was Mr.

Baldwin's invention of ground joints for steam pipes, which was a very valuable

improvement over previous methods of making joints with red-lead packing, and

which rendered it possible to carry a much higher pressure of steam.

4.

A new mode of forming the joints and other parts of the supply pump, and of

locating the pump itself. This invention consisted in making the single guide

bar hollow and using it for the pump barrel. The pump plunger was attached to

the piston rod at a socket or sleeve formed for the purpose, and the hollow

guide bar terminated in the vertical pump chamber. This chamber was made in two

pieces, joined about midway between the induction and eduction pipes. This

joint was ground steam-tight, as were also the joints of the induction pipe

with the bottom of the lower chamber, and the flange of the eduction pipe with

the top of the upper chamber. All these parts were held together by a stirrup

with a set-screw in its arched top, and the arrangement was such that by simply

unscrewing this set-screw the different sections of the chamber, with all the

valves, could be taken apart for cleaning or adjusting.

Pump and Stirrup

It

is probable that the five engines built during 1834 embodied all, or nearly

all, these devices. They all had the half-crank, the ground joints for steam

pipes (which were first made by Mr. Baldwin in 1833), and the pump formed in

the guide bar, and all had the four-wheeled truck in front, and a single pair

of drivers back of the firebox. On this position of the driving wheels Mr.

Baldwin laid great stress, as it made a more even distribution of the weight,

throwing about one-half on the drivers and one-half on the four-wheeled truck.

It also extended the wheel base, making the engine much steadier and less

damaging to the track. Mr. William Norris, who had established a locomotive

works in Philadelphia in 1832, was at this time building a six-wheeled engine

with a truck in front and the driving wheels placed in front of the firebox.

Considerable rivalry naturally existed between the two manufacturers as to the

comparative merits of their respective plans. In Mr. Norris's engine, the

position of the driving axle in front of the firebox threw on it more of the

weight of the engine, and thus increased the adhesion and the tractive power.

Mr. Baldwin, however, maintained the superiority of his plan, as giving a better

distribution of the weight and a longer wheel base, and consequently rendering

the machine less destructive to the track. As the iron rails then in use were

generally light, and much of the track was of wood, this feature was of some

importance.

To

the use of the ground joint for steam pipes, however, much of the success of

his early engines was due. The English builders were making locomotives with

canvas and red-lead joints. permitting a steam pressure of only 60 pounds per

square inch to be carried, while Mr. Baldwin's machines were worked at 120

pounds with ease. Several locomotives imported from England at about this

period by the Commonwealth of Pennsylvania for the State Road, which were built

by Robert Stephenson & Co., had canvas and red-lead joints, and their

efficiency was so much less than that of the Baldwin engines, on account of

this and other features of construction, that they were soon laid aside or

sold.

In

June, 1834, a patent was issued to Mr. E. L. Miller, by whom Mr. Baldwin's second

engine was ordered, for a method of increasing the adhesion of a locomotive by

throwing a part of the weight of the tender on the rear of the engine, thus

increasing the weight on the drivers. Mr. Baldwin adopted this device on an

engine built for the Philadelphia and Trenton Railroad Company, May, 1835, and

thereafter used it largely, paying $100 royalty for each engine. Eventually

(May 6, 1839) he bought the patent for $9,000, evidently considering that the

device was especially valuable, if not indispensable, in order to render his

engine as powerful, when required, as other patterns having the driving wheels

in front of the firebox, and therefore utilizing more of the weight of the

engine for adhesion.

In

making the truck and tender wheels of these early locomotives, the hubs were

cast in three pieces and afterward banded with wrought iron, the interstices

being filled with spelter. This method of construction was adopted on account

of the difficulty then found in casting a chilled wheel in one solid piece.

Early

in 1835, the new shop on Broad Street was completed and occupied. Mr. Baldwin's

attention was thenceforward given to locomotive building exclusively, except

that a stationary engine was occasionally constructed.

In

May, 1835, his eleventh locomotive, the "Black Hawk," was delivered

to the Philadelphia and Trenton Railroad Company. This was the first outside

connected engine of his build. It was also the first engine on which the Miller

device of attaching part of the weight of the tender to the engine was

employed. On the eighteenth engine, the " Brandywine," built for the

Philadelphia and Columbia Railroad Company, brass tires were used on the

driving wheels, for the purpose of obtaining more adhesion; but they wore out

rapidly and were replaced with iron.

April

3, 1835, Mr. Baldwin took out a patent for certain improvements in the wheels

and tubes of locomotive engines. That relating to the wheels provided for

casting the hub and spokes together, and having the spokes terminate in segments

of a rim, as described in his patent of September 10, 1834. Between the ends of

the spokes and the tires, wood was interposed, and the tire might be either of

wrought iron or of chilled cast iron. The intention was expressed of making the

tire usually of cast iron chilled. The main object, however, was declared to be

the interposition between the spokes and the rim of a layer of wood or other

substance possessing some degree of elasticity. This method of making driving

wheels was followed for several years, the tires being made with a shoulder, as

illustrated below.

Driving Wheels, Patented

September, 1834

The

improvement in locomotive tubes consisted in driving a copper ferrule or

thimble on the outside of the end of the tube, and soldering it in place,

instead of driving a ferrule into the tube as had previously been the practice.

The object of the latter method had been to make a tight joint with the tube

sheet; but by putting the ferrule on the outside of the tube, not only was the

joint made as tight as before, but the tube was strengthened, and left

unobstructed throughout to the full extent of its diameter. This method of

setting tubes has been generally followed in the Works from that date to the

present, the only difference being that, at this time, with iron or steel

tubes, the end is wedged down, the copper ferrule brazed on, and the end of the

tube turned or riveted over against the copper thimble and the flue sheet to

make the joint perfect.

Fourteen

engines were constructed in 1835; 40 in 1836; 40 in 1837; 23 in 1838; 26 in

1839, and nine in 1840. During all these years the general design continued the

same; but, in coinpliance with the demand for more power, three sizes were

furnished, as follows:

First class-- Cylinders, 12-1/2 x 16”; weight loaded,

26,000 pounds.

Second class--Cylinders, 12" x 16";

" 23,000 “

Third class-- Cylinders, 10-1/2 x 16"; " 20,000 “

Mr.

Baldwin fuly believed, in 1838, that the first class engine was as heavy as

would be called for, and he declared that it was as large as he intended to

build. Most of the engines had the half-crank, but occasionally an

outside-connected machine was turned out. These latter, however, failed to give

as complete satisfaction as the half-crank machine. The drivers were generally

54 inches in diameter.

A

patent was issued to Mr. Baldwin, August 17, 1835, for his device of

cylindrical pedestals. In this method of construction, the pedestal was of cast

iron, and was bored in a lathe so as to form two concave jaws. The boxes were

also turned in a lathe so that their vertical ends were cylindrical, and they

were thus fitted in the pedestals. This method of fitting up pedestals and

boxes was cheap and effective, and was used for some years for the driving and

tender wheels.

As

showing the estimation in which these early engines were held, it may not be

out of place to refer to the opinions of some of the railroad managers of that

period.

Mr.

L. A. Sykes, engineer of the New Jersey Transportation Company, under date of

June 12, 1838, wrote that he could draw with his engines 20 four-wheeled car,

with 26 passengers each, at a speed of 20 to 25 mile, per hour, over grades of

26 feet per mi1e. "As to simplicity of construction," he adds,

"small liability to get out of order, economy of repairs, and ease to the

road, I fully believe Mr. Baldwin's engines stand unrivalled. I consider the

simplicity of the engine, the arrangement of the working parts, and the

distribution of the weight, far superior to any engine I have ever seen, either

of American or English manufacture, and I have not the least hesitation in

saying that Mr. Baldwin's engine will do the same amount of work with much less

repairs, either to the engine or the track, than any other engine in use."

L.

G. Cannon, President of the Rensselaer and Saratoga Railroad Company, writes:

"Your engines will, in performance and cost of repairs, bear comparison

with any other engine made in this or any other country."

Some

of Mr. Baldwin's engines on the State Road, in 1837, cost, for repairs, only

from 1.2 to 1.6 cents per mile. It is noted that the engine "West

Chester," on the same road, weighing 20,735 pounds (10,475 on drivers),

drew 51 cars (four-wheeled), weighing 289 net tons, over the road, some of the

track being of wood covered with strap-rail.

The

financial difficulties of 1836 and 1837, which brought ruin upon so many, did

not leave Mr. Baldwin unscathed. His embarrassments became so great that he was

unable to proceed, and was forced to call his creditors together for a

settlement. After offering to surrender all his property, his shop, tools,

house and everything, if they so desired -- all of which would realize only

about 25 per cent of their claims -- he proposed to them that they should

permit him to go on with the business, and in three years he would pay the full

amount of all claims, principal and interest. This was finally acceded to, and

the promise was in effect fulfilled, although not without an extension of two

years beyond the time originally proposed.

In

May, 1837, the number of hands employed was 300, but this number was reduced

weekly, owing to the falling off in the demand for engines.

These

financial troubles had their effect on the demand for locomotives, as will be

seen in the decrease in the number built in 1838, 1839 and 1840; and this

result was furthered by the establishment of several other locomotive works,

and the introduction of other patterns of engines.

The

changes and improvements in details made during these years may be summed up as

follows:

The

subject of burning anthracite coal had engaged much attention. In October,

1836, Mr. Baldwin secured a patent for a grate or fireplace which could be

detached from the engine at pleasure, and a new one with a fresh coal fire

substituted. The intention was to have the grate with freshly ignited coal all

ready for the engine on its arrival at a station, and placed between the rails

over suitable levers, by which it could be attached quickly to the firebox. It

is needless to say that this was never practiced. In January, 1838, however,

Mr. Baldwin was experimenting with the consumption of coal on the Germantown

road, and in July of the same year the records show that he was making a

locomotive to burn coal, part of the arrangement being to blow the fire with a

fan.

The

first locomotives for export were built during this year. They were shipped to

Cuba, to the order of Alfred Cruger, and bore the builder's numbers 104 and

105. These locomotives were completed in the spring and summer, and were

followed by a third later in the year.

Up

to 1838, Mr. Baldwin had made both driving and truck wheels with wrought tires,

but during that year chilled wheels for engine and tender trucks were adopted.

His tires were furnished by Messrs. S. Vail & Son, Morristown, N. J., who

made the only tires then obtainable in America. They were very thin, being only

one inch 1-1/2 inches thick; and Mr. Baldwin, in importing some tires from

England at that time, insisted oil their being made double the ordinary thickness.

The manufacturers at first objected and ridiculed the idea, the practice being

to use two tires when extra thickness was wanted, but finally they consented to

meet his requirements.

All

his engines thus far had the single eccentric for each valve, but at about this

period double eccentrics were adopted, each terminating in a straight hook, and

reversed by hand levers.

At

this early period, Mr. Baldwin had begun to feel the necessity of making all

like parts of locomotives of the same class in such manner as to be absolutely

interchangeable. Steps were taken in this direction, but it was not until many

years afterward that the system of standard gauges was perfected, which became

a distinguishing feature in the establishment.

In

March, 1839, Mr. Baldwin's records show that he was building a number of

outside-connected engines, and had succeeded in making them strong and durable.

He was also making a new chilled wheel, and one which he thought would not

break.

On

the 136th locomotive, completed October 18, 1839, for the Philadelphia,

Germantown and Norristown Railroad, the old pattern of wooden frame was

abandoned, and no outside frame whatever was employed-the machinery, as well as

the truck and the pedestals of the driving axles, being attached directly to

the naked boiler. The wooden frame thenceforward disappeared gradually, and an

iron frame took its place. Another innovation was the adoption of eight-wheeled

tenders, the first of which was built at about this period.

On

April 8,1839, Mr. Baldwin associated with himself Messrs. Vail & Hufty, and

the business was conducted under the firm name of Baldwin, Vail & Hufty

until 1841, when Mr. Hufty withdrew, and Baldwin & Vail continued the

co-partnership until 1842.