Neath Abbey Iron Works

According to his biographies, Hopkin Thomas joined the Neath Abbey Ironworks as an apprentice in 1809. No information exists on how long he was apprenticed. His biography does state: He early developed a fertile brain, and on fulfilling his apprenticeship speedily attained a high position among his fellow-workmen. Assuming he was at N. A. I. W. during the decade of 1810 – 1820, these are the disciplines to which he would have been exposed.

- Iron smelting

- Forging

- Casting

- Metal working (turning, boring, milling)

- Stationary Steam Engine Design (Beam Engines)

- High-pressure Steam Engine Design

- Marine Engine Design

- Locomotive Engine Design.

- Ship design

Indeed, the Ironworks was the M. I. T. of its day, reputed to be one of the greatest engineering concerns in Great Britain – and it was only a short carriage ride from Bryncoch where Hopkin grew up. This was an ideal situation to be trained in the discipline which would eventually become known as Mechanical Engineering.

The physical complex that housed all this activity was modest in size. An aerial view below taken in 1997 shows the ruins of the two masonry blast furnaces and the remaining walls of the shops to the left.

The viaduct to the right was a tramway for horse-drawn carts filled with coke, ore, and limestone. The blast furnaces were built into a hillside so that the carts had easy access to the charging platforms – shown below. Today, the tramway is the main Swansea to London rail connection.

To the right of the viaduct, not visible in the photo flows the Clydach river. The waterfalls on the river supplied the water power to turn the machinery in the early days. Later, steam power was developed for that purpose.

Below are two recent shots (more info and pictures here) of the shop walls. Note the iron supports attached to the rear wall – this supported a trough which delivered water from the Clydach to a water wheel at the shop site. In 1996, when I visited the site, there was extensive work being done to stabilize the walls. There has been some indication that the site will be rehabilitated and serve as a visitor center, but no official announcements to that effect.

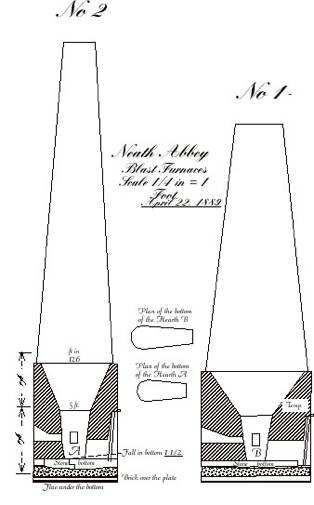

When erected in the 1790Õs, the masonry blast furnaces were said to be among the largest yet built. The furnaces were blown by a double-acting Boulton and Watt steam engine featuring a 40-in. dia. cylinder.

More information on the details of the furnaces and other aspects of the complex is found in a 1974 article by D. Morgan Rees contained in the proceedings of a symposium on Neath compiled by Elis Jenkins.

This cauldron of industrial activity, vividly described by visitors, did not materialize out of nothingness. Rather there was a history of copper smelting, coal mining and iron production within the Clydach valley. That history, and subsequent operations at Neath Abbey, are thoroughly reviewed in a scholarly work by Laurence Ince. The scope of InceÕs treatise is summarized by the contents list. Of particular interest are the Appendices which list the machinery and ships built throughout the years. We can gain an overview of the activities to which Hopkin Thomas was exposed during the 1810 – 1820 decade.

First, it is almost certain that any apprentice would become thoroughly versed in the iron-making trade. It is said that Neath Abbey operated its furnaces almost exclusively for the production of iron for its own use – not for sale to others. The process used at Neath Abbey was based on the utilization of coke as fuel. As we shall see, Hopkin became Master Mechanic at the Crane Iron Works in Pennsylvania where anthracite was used in iron-making, but he trained many engineers who were successful in employing coke in other regions of America. (Including his son James who oversaw the development of coke furnaces in Alabama.)

According to InceÕs table, a variety of stationary steam engines would have been assembled in the Neath shops during HopkinÕs tenure – high-pressure engines based on TrevithickÕs design and low pressure beam and rotative engines. Cutomers included the Cyfartha and Dowlais Iron works in the Merthy Tydfil area where it is believed that Hopkin eventually worked.

Marine engines were constructed in the 1820Õs – there is no evidence that Hopkin had contact with that technology.

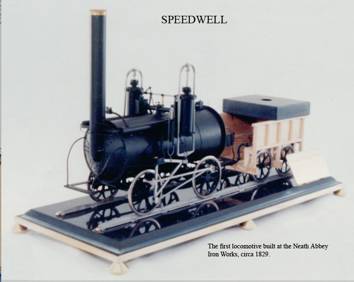

Finally, it was not until the 1826-1830 time period that the first locomotive was built at Neath Abbey – the Speedwell. A photograph of a museum model of the Speedwell built by Rob Preston is shown below – it had vertical cylinders and was driven through a bell crank.

It is doubtful that Hopkin was still at Neath Abbey at the time this engine was designed. Hopkin had married Catharine Richards of Merthyr Tydfil (date unknown). Their first child was William Richards Thomas, born in, according to his biography, Merthyr Tydfil on May 29, 1829. Therefore it is most likely that Hopkin had taken a position at one of the iron manufactories in the Merthyr area sometime prior to the Neath Abbey Ironworks getting into the locomotive design and construction business..

One avenue for pursuit of the career of Hopkin at Neath Abbey that requires attention is an examination of the records of the Ironworks which are held at the West Glamorgan Record Office. In private communications with Prof. Ince, it was confirmed that the records still preserved are voluminous. However, Prof. Ince, not surprisingly, could not provide any information relevant to Hopkin Thomas nor on whether the engineering drawings on file were signed by the creator as became the practice in America in the mid-nineteenth century. Even a cursory examination of the thousands of documents preserved will require the better part of a week, but the process needs to be conducted before this chapter in HopkinÕs career can be closed.

Return to the Table of Contents

About The Hopkin Thomas

Project