Richard Trevithick

Richard Trevithick was a Cornish engineer who made significant contributions to steam locomotion at the turn of the 18th century. He was aggressive, authoritative, and very inventive. He was a prolific builder and erector of stationary steam engines, but his most widely recognized contribution was the first successful use of a high-pressure steam engine to drive a locomotive on iron rails. This was the famous Penydarran trial carried out in 1804. His contributions have been memorialized by the erection of monuments in the Penydarran site in Merthyr Tydfil.

Richard Trevithick

Trevithick’s life story has been recorded in superb detail in a book authored by his son, Francis, also an engineer. The book indicates what a prolific inventor this man was – it is now available on CD and is well worth reading. For our purposes, we are going to focus on the Penydarran trial.

Trevithick recognized that the secret to steam locomotion was the employment of a high pressure steam cycle. James Watt, on the other hand, felt that the danger from boiler explosions was too great, so Watt pursued atmospheric pressure engines. This approach was doomed, as there was no way to achieve high power with reasonable engine weight. In addition, atmospheric engines required a condenser to develop a vacuum on the low pressure side of the piston. Trevithick pursued the high-pressure boiler and did not employ a condenser.

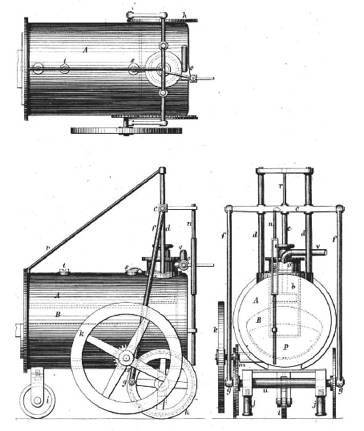

Years of study and design went by before the first of his steam locomotives was demonstrated. The first vehicle was a road vehicle that ran on iron wheels – not on rails. A working model of this vehicle has been preserved at the Kensington Museum. It employs many of the features used on the Penydarran engine:

The description of this

working model shadows forth the usefulness of the high-pressure steam-engine of

the present day in many of its leading features; the non-necessity for

condensing water, the cylindrical boiler, the simplest form of crank, the

absence of mason-work for the engine or boiler flues, and its portability and

power of locomotion, so nearly met all the requirements, as to entitle it to

the designation, “the first high-pressure locomotive. "P is the

iron-heater (used in the model to avoid smoke); s, the safety-valve, kept

down by a simple spring; t, screw-plug for supplying water; b, steam-cylinder let

into boiler, with shell for the four-way cock, and pipe for conveying steam to

the top and bottom of cylinder cast with it; o, a four-way steam-cock,

worked by a rod from the cross-bead; c, the cross-bead; f, the two side rods; g, the crank-pins

attached to the two driving wheels; i, the steering wheel, fixed by a screw for

running in curved or straight lines; e, piston-rod ; d, guides for the

piston-rod cross-head; h, two driving wheels; j, two legs, by screwing out the lower

part of which the driving wheels are lifted off the ground, making a stationary

engine; k,

fly-wheel.; m, pinion and gear wheel, connecting the fly-wheel with the driving

wheel; n,

plug-rod attached to cross-head for moving the four-way cock; r, stay for the

guide-rods ; u,

driving axle; v,

waste-steam pipe; A, the cylindrical boiler, made of copper; B, the

boiler-tube.

The

pressure in the boiler was 50 – 60 psi. Again, others including James

Watt objected to the use of high pressure because of the danger of bursting.

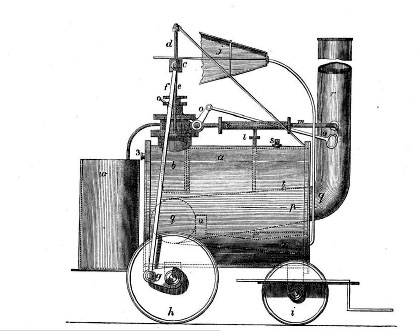

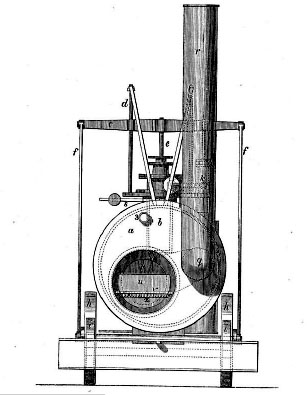

The

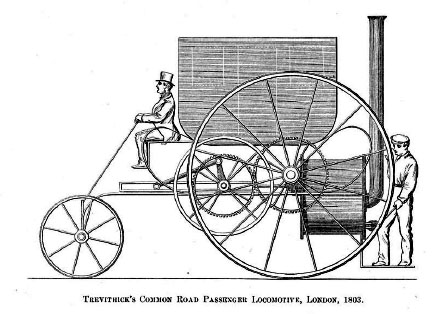

original vehicle on which the above

Kensington Model is based was known as the Common Road Locomotive,

Camborne and was constructed in 1801. No drawings of the actual engine

survived, but Trevithick’s son created the sketches shown below. His commentary

follows the top (plan) view.

Trevithick’s First Passenger- carrying

Common Road Locomotive, Camborne; 1801.

a, cylindrical boiler

with wrought-iron ends, having inside it a wrought-iron tube bent as the letter

U ; p.

the fire-place,, in one end of the tube; v, fire-bars ; u, fire~bridge ; z, the ash-pit ; q, the return flue,

leading to r,

the chimney-the fire-door is not shown, as it would confuse the drawing; z, the steam-gauge ; s, safety-valve ; t, soft metal safety-plug

in top of fire-tube; j, the bellows, blowing air into the close ash-pit, fixed to the

guide-stays, and worked by the arm of its movable middle division connected

with the piston-rod cross-head; b, steam-cylinder let into the boiler, having a

close top and bottom, with pipe for conveying steam to and from the bottom, and

also the shell for the four-way steam-cock, and the steam-way from the boiler,

all cast with the cylinder; o, a four-way steam-cock, worked by a rod from

the cross-head, with two tappets striking the lever, o, up and down, and

having a handle, o,

suitable for the engineman; k, the feed pole-pump, worked from the

cross-head; l,

the feed-pipe; w,

feed-water cistern; n, case for heating feed-water by the passage of the waste

steam through m,

the waste-steam pipe, from the cylinder to the chimney; c. the cross-head; f the two side rods; g, the two cranks; h, two driving wheels; i, two steering wheels; e. piston-rod ; d, guides for the

piston-rod cross-head.

Writer Francis Trevithick notes:

No original drawing

remains of this first passenger-carrying locomotive engine, but from the

description of those who saw it, there is little doubt of the general

correctness of the drawing made by the writer.

One of the gains from

the Trevithick high-pressure engine was its portability and cheapness, when

compared with the Newcomen or the Watt engine, neither of which could work

without condensing water which locomotive engines cannot procure.

This engine had little

or no resemblance to any steam-engine that had preceded it. No stone foundation,

air-pump, condenser, condensing water, beam, or parallel motion, all the

improvements of fifty years thrown aside; and the great and costly boiler of

his predecessors was replaced by one so small that it seemed merely a part of

the engine, as a stand-point on which to fix the mechanism.

The boiler was

cylindrical, of cut iron, in which the steam-cylinder was fixed; the

tubular-boiler flues were of wrought iron, and entirely within the boiler.

The exhausted steam

having done its work in the cylinder, at a pressure of 60 lbs. to the inch,

passed into the chimney as a steam-blast, causing an intensely hot fire, and in

its passage heated the feed-water.

The boiler-flues,

together with the steam-cylinder, filled up a large portion of the interior of

the boiler, reducing the weight of water carried to its lowest possible

requirement, while a feed-pump, steam-gauge, safety-valve, and soft metal plug

in the fire-tube, gave accurate supply of water, or escape of steam.

The fee-pole was

constructed precisely like the plunger-poles he had fixed in the mine-shafts,

and is unchanged to the present day.

Low-pressure boilers had

no feed-pumps, being supplied by gravity of the water from a cistern above the

boiler.

The heating the

feed-water by the waste steam was also an application originating with him. The

steam cylinder bad its steam-pipe and bottom cast as a part of it. The inlet

and outlet of steam was performed by one simple piece called Trevithick's

four-way cock. The piston-rod, cross-head, guiderods, and connecting rods, were

all of simple form. The boiler served as a framing for keeping the four wheels

in their proper places. and also the cylinder and working parts. The two front

or steering wheels were turned by a rod conveniently placed close to the

engineman attending at the fire-door.

One result of theme experiments was the immediate

application for a patent, granted on the 24th March, 1802, to

Richard Trevithick and Andrew Vivian, for steam-engines for propelling

carriages &c., which may be read and studied by the young engineer with

pleasure and profit even in “this" age of greatly improved steam

mechanism.

There

followed experiments with another common road engine – the London Common

Road engine. This peculiar affair was equipped with very large wheels so better

to negotiate rough terrain.

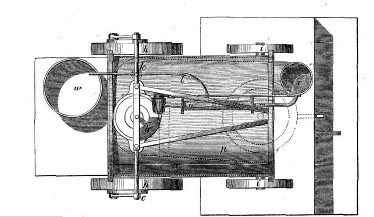

Having

given a few months to the successful experiments with the London common road

engine, and to the erection of high-pressure engines, in rivalry with Watt's

low-pressure, steam vacuum engines, he was, in October, 1803, busily engaged in

constructing at Penydarran, in South Wales, a tramway locomotive, to run on

rails not exceeding an elevation of 1 in 60, and of considerable length.

Penydarran – Site

of the Famous Trevithick Engine Trial

The events of the trial

are told in letters to his sponsors. One interesting aspect was that a skeptic

had placed a bet with Mr. Homfray – a sponsor – in the amount of

500 guineas that the locomotive would not be able to draw a useful load (ten

tons) as there would be little traction between the wheel and the rail –

this, of course, was a key element of the trials.

“

Mr. Giddy, “Penydarran,

15th February, 1804

" Sir, - Last

Saturday we lighted the fire in the tram-waggon, and worked it without the

wheels to try the engine. On Monday we put it on the tramroad. It worked very

well, and ran up hill and down with great ease, and was very manageable. We had

plenty of steam and power. I expect to work it again tomorrow. Mr. Homfray and

the gentleman I mentioned in my last, will be home tomorrow. The bet will not

be determined until the middle of next week, at which time I shall be very

happy to see yon.,

Your

humble servant

Richard

Trevithick."

The

first tramroad. locomotive in Wales worked in the month of February, 1804,

running with facility up and down inclines of I in 50, and having a full supply

of steam and. power.

“ Mr. Giddy, “Penydarran,

20th February, 1804

“Sir,--The tram-wagon has

been at work several times. It works exceedingly well, and is much more

manageable than horses, We have not tried to draw more than 10 tons at a time,

but I doubt not we could draw 40 tons at a time very well; 10 tons stand no

chance at all with it. We have been but two miles on the road and back again,

and shall not go farther until Mr. Homfray comes home. He is to dine at

home to-day, and the engine goes down to meet him.. The engineer from the

Government is with him.

"The engine, with

water included, is about 5 tons. It runs up the tramroad of 2 inches in a yard forty strokes per minute with

the empty waggons.The engine moves forward 9 feet at every stroke. The public

are much taken up with it. The bet of 500 guineas will be decided about the end

of this week. Your presence would give me more satisfaction than you can

conceive, and I doubt not you will be fully repaid for the toil of the journey

by a sight of the engine.

“The steam that is

discharged from the engine is turned up the chimney about 3 feet aboys the

fire, and when the engine works forty strokes per minute, 4-1/2 feet stroke,

8-1/4 inches diameter of cylinder, not the smallest particle of steam appears

out of the top of the chimney, though it is but 8 feet above where the steam is

delivered into it, neither at a distance from it is steam or water found. I

think it is made a fixed air by the heat of the chimney. The fire burns much

better when the steam goes up the chimney than when the engine is idle. I

intend to make a smaller engine for the road, as this has much more power than

is wanted here. This engine is to work a hammer.

" The engineer from

London will try a great many experiments with these engines, as that is his

sole business here, and that is my reason for so much wishing you here. He

intends to try the strength of the boiler by a force-pump, and has sent down

orders to get long steam-gauges and force-pumps ready for that purpose.

“We shall continue our

journey on the road to-day with the engine, until we meet Mr. Hornfray and the

London engineer, and intend to take the horses out of the coach, fasten it to

the engine, and draw them home. The other end of the road is 9-3/4 miles from

here. The coach-axles are the same length as the engine-axles, so the coach

will run very easily on the tram road.

“There have been several

experiments made by Mr. Homfray and this engineer in London, lately, on these

engines. I am very much obliged to you for your offer to assist, in making out

a publication of the duty and advantages of those engines. As soon as I can get

proper specimens at work, and you as an eyewitness of their performance, I

shall value your kind offer and assistance far beyond any other to be got as

you have been consulted, and have assisted me from the beginning.

I

am, Sir,

Richard

Trevithick."

“ Mr. Giddy, “Penydarran,

15th February, 1804

“Sir, - Yesterday we

proceeded on our journey with the engine; we carried 10 tons of iron, five waggons,

and seventy men riding on them the whole of the journey. It is above nine

miles, which we performed in four hours and five minutes. We had to cut down

some trees and remove some large rocks out of the road. The engine, while

working, went nearly five miles per hour; no water was put into the boiler from

the time we started until we arrived at our journey's end. The coal consumed

was 2 cwt. On our return home, about four miles from the shipping-place of the

iron, one of the small bolts that fastened the axle to the boiler broke, and

all the water ran out of the boiler, which prevented the return of the engine

until this evening. The gentleman that bet 500 guineas against it rode the

whole of the journey with us, and is satisfied that he has lost the bet We

shall continue to work on the road, and shall take 40 tons the next journey.

“The public until now

called me a scheming fellow, but now their tone is much altered. An engine is

ordered for the West India Docks, to travel itself from ship to ship, to unload

and to take up the goods to the upper floors of the storehouses by the crane,

and in case of fire to force water on the storehouse. The fire is to be kept

constantly burning in the engine, so as to be ready at all times.

" Boulton and Watt

have strained every nerve to get a Bill in the House to stop these engines

saying the lives of the public are endangered by them, and I have no doubt they

would have carried their point if Mr. Homfray had

not gone to London to prevent it; in consequence of which an engineer from

Woolwich was ordered down, and one from the Admiralty Office, to inspect and

make trial of the strength of the materials, and to prove that the steam-gauges

will admit steam through them in case the steam-valve should be fastened down. They

are not to come until everything is complete for those experiments You shall

know of our future experiments as fast as we get on with them.

Your

humble servant

Richard

Trevithick."

Before

a week had passed, from the first getting-up of steam, this pioneer of

railway-engines had run several times, drawing a load of 10 tons, and was more

controllable than horses'. Only two miles of road were to be run over during

the first trials, but within the week the engine ran a distance of 9-3/4 miles.

The horses were removed from Mr. Homfray common road coach, the wheels of which

were of the same gauge as the tramway, and it was drawn by the engine, together

with Mr. Homfray and his companion, a Government engineer, brought down for the

purpose of examining and testing Trevithicks engines. This was a practical

proof of how street tramway engines could be made to draw by steam ordinary

road carriages.

The

engine in working order weighed about 5 tons; its cylinder was 8-1/4 inches in

diameter, with a stroke of 4-1/2 feet. It took empty waggons up an incline of 2

inches in a yard, at forty strokes a minute, progressing 9 feet at each stroke;

in other words, it took its load up an incline of 1 in 18 at the rate of four

miles an hour.

Trevithick's

own words solve the blast-pipe riddle

“The steam that is

discharged from the engine is turned up the chimney, about three feet above the

fire. The fire burns much better when the steam goes up the chimney than when

the engine is idle."

It

was something like engineering, that within a week of first putting fire in a

newly-designed engine for a novel purpose, it took in the morning its

luggage-train work up an incline believed by many to be dangerously

unmanageable even now, after seventy years of experience, and was prepared for

its evening passenger-train work, to bring home the ironmaster and his friend,

snugly riding in an ordinary horse-carriage.

Trevithick

was anxious that Mr. Davies Gilbert should be near him to observe the drift of

events, for he knew the London engineer had been experimenting with his

high-pressure engines then at work in London, in competition with Watt; and be

also hoped that Davies Gilbert would make public a report on the advantages of

the new principle of working without a vacuum, and state what he had seen at

Penydarran.

Immediately

after writing a long letter, giving clear and important facts, during the din

and hurry of preparing the tramroad-engine for her first long run, a start was

made from Penydarran for the Basin, 9-3/4 miles distant. Five waggons were

attached to the engine, loaded with 10 tons of iron and seventy men. Four hours

and five minutes were required for the journey, though the engine went at the

rate of five miles an hour, but was obliged to stop frequently that trees might

be cut down and rocks removed that blocked the roadway. How different to the

well-prepared level railway on the Liverpool and Manchester line, on which the

much-talked-of locomotives ran a quarter of a century later!

The

gentleman who bet 500 guineas that the engine would not draw 10 tons of iron

over the distance, rode with Trevithick, and admitted the fact. The seventy men

and tools taken at 7 tons, made a net load of 17 tons; and, including the five

waggons, a gross load of 25 tons. During the journey, 2 cwt. of coal were

consumed, and Trevithick believed, from that day's experience, that he could

take a load of 40 tons.

On

the return journey, when four miles had been passed, one of the bolts fastening

the axle-boxes to the boiler broke, the water and steam escaped through the

hole, and caused the engine to stop for repairs.

Writes

son Francis Trevithick: “This roughly-constructed locomotive performed a

comparatively long journey with a heavy load, over the worst possible road,

with sharp curves and inclines, and frequently breaking tram-plates; yet such,

to other men, insurmountable difficulties are not so much as mentioned in

Trevithick's letters.”

However,

it was the breaking of the tram-plates that discouraged further efforts on

utilizing steam locomotion on the existing tram-roads. In effect, until the

tram roads were constructed using stronger designs, no locomotives would be put

into use. Because re-constructing the roads was an expensive proposition,

developments languished.

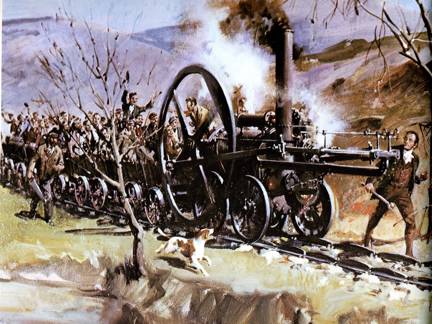

Extract

of Terence Cuneo’s painting of the Trevithick trial,

see Ellis, The

Lore of the Train.

A

further account of Trevithick’s activity, published

by The Industrial Railway Record can be found here.

Return

to Steam Locomotive Development

About

the Hopkin Thomas Project

Updated November 2009