The Norris Locomotive

Works

Sources: John H. White,

Jr.; Wikipedia

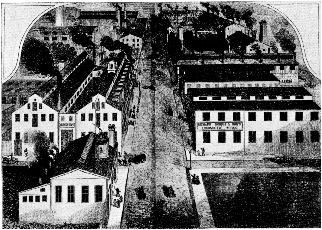

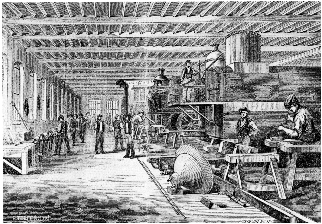

Fig. 1. The Norris

Locomotive Works in 1855, at the time the largest manufacturer of railway

engines.

The

Norris Locomotive Works was a steam locomotive manufacturing company based in

Philadelphia that produced about a thousand engines between 1836 and 1860. It

was the dominant American locomotive producer during most of that period, and

was even selling its popular 4-2-0 locomotives to European railways. The Norris

factory evolved from a small shop in a converted stable in 1834 to a mighty

industrial works located in central Philadelphia by 1855. The firm's factory

complex was located in the area around 17th and Hamilton Streets on several

acres of what had been the famous Bush Hill estate. The site was near the

right-of-way of the Philadelphia and Columbia Railroad, which crossed through

that part of Philadelphia just north of Callowhill

Street. (This route was later owned by the Reading Railroad.)

An 1855 ad giving the

location of the Norris Works.

The company was more or less started in 1832 as the American Steam Carriage Company by William Norris (1802-1867) and Col. Stephen H. Long (1784-1864). The two men had experimented in locomotive building for years and as early as 1829 had designed a locomotive to burn anthracite coal. Norris and Long also built an engine called the Black Hawk, which performed with partial success on the Boston and Providence Railroad, and the Philadelphia and Columbia Railroad in the early 1830s. Long, a famed engineer, explorer and military officer, later left the firm and William was joined by his brother Septimus, who patented several locomotive-related inventions.

The two brothers reformed the enterprise into the Norris Locomotive Works. On July 10, 1836, they ran a test of a 4-2-0 locomotive on the Belmont Inclined Plane of the Philadelphia and Columbia Railroad. This was one of the most historic events in railroading history. The two-track incline ran from the Schuylkill River for 2,805 feet towards present-day Belmont Avenue, rising one foot in 15 for a total of 187 feet. Named George Washington, the 14,400 pound locomotive hauled a load of 19,200 pounds (including 24 people riding on tender and one freight car) up the grade at 15 miles per hour. This engine, the first to ascend a hill by its own power, proved that a steam locomotive could climb an ascending grade while pulling a load. So remarkable was this accomplishment that reports in engineering journals emphatically doubted its occurrence. A second, more formal trial with an even greater load proved the engine's capabilities on July 19, 1836.

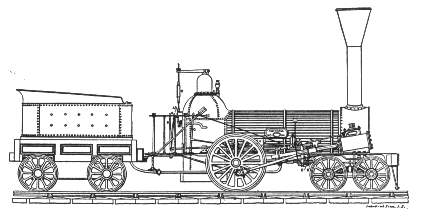

Fig. 2. An Early Norris 4-2-0

Norris built the Lafayette for the Baltimore and Ohio Railroad the following year. Named after the Marquis de Lafayette, this 4-2-0 engine was the first locomotive to feature a leading truck and may have been the first standardized production model locomotive. Innovations included the positioning of cylinders ahead of the smokebox and the four-wheel swiveling pilot truck. The Lafayette established the configuration steam locomotives would follow until the end of the steam era.

In 1847, the Norris Works built the first ten-wheel locomotive in America: the Chesapeake. Operated by the Philadelphia and Reading Railroad, this was also the world's first 4-6-0 locomotive. It weighed 22 tons and had 14½ by 22 inch cylinders and driving wheels 46 inches in diameter. Initially a wood-burning locomotive, the Chesapeake was converted to burn anthracite coal in 1862, and ran for about another fifteen years. Some authorities claim that Septimus Norris came up with the design, but other sources attribute it to master builder John Brandt.

Fig. 3. A Norris 4-6-0

The

ten buildings (Fig. 1), many of them three-story brick structures, and the

machinery and stock were valued at one million dollars.

The

shops and their over-all floor size are listed below:

Steam Hammer Shop 801 x 1041

Truck Shop 68' x 1001

Tank Shop 30' x 1001

Boiler Shop 80' x 100'

Erecting Shop 130' x 179'(2 buildings)

Engine Room and Stables 200' x 254'

Blacksmith 1161 x 1531

Finishing 1531 x 166'

Foundry 701 x 103'

Office and Drafting size not given

The

erecting or assembly shop is the three-story double building to the left of the

center of Fig. 1. Twenty-four tracks were served by a combination

transfer-turntable located in the open central court between the two

structures.

The

procedure for building a locomotive was well organized. After an order was

cleared by the front office the engineering department prepared a lengthy

specification on printed forms. Pertinent portions of these forms were sent to

the foundry, hammer shop, and the other shops involved so that the needed parts

would be made. When finished, the pieces were brought to the erecting shop for

assemblage in the following sequence:

First, the boiler is placed and

accurately leveled - the frame is set and fastened - the braces are set and

fastened - the check and whistle stands are riveted fast - set the cylinder -

then the rock arms and pedestals, the oiler flues put in- the driving boxes are

put up and laid out for boring - the center pin set - the driver and the guides

are set - pumps put up – next the reversing shafts - the footplate put on

and fastened - the valve rod and valves - the steam pipes - the throttle valve

- the dome -the safety valve -the feed and supply pipes -the wheels -the

eccentric hooks - the connecting rods - the valves set - and the whole of the

working part, being now about together, steam is raised, and after "giving

her a good blowing out," to get rid of dirt, etc., the cylinder heads are

screwed on and the working of the new engine thoroughly tested. At these times

the senior proprietor is always present.

When

the assemblage was completed, the machine was moved across the transfer table

to the opposite building for finishing and painting. An

engine could be assembled by a fourteen-man crew in fifteen days.

Another two weeks were required for preparing the parts for assembly; this

included casting, forging, and machining. Thus, total fabricating time was

about thirty days. It might be noted that in 1880 Baldwin required four to five

weeks for assembly, not including the preliminary work needed for the

preparation of the parts.

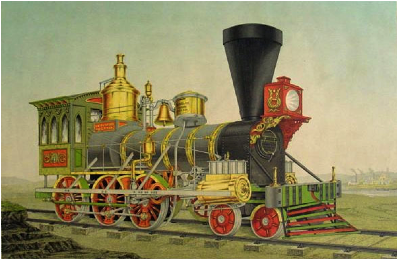

Fig. 4. Interior of the erecting

shop at the Norris Locomotive Works, 1855 .

Richard

Norris and Son was the largest locomotive manufacturer in the United States, if

not the world, during the 1850s. Six to seven hundred men were employed in

1855, but times were dull; as many as eleven hundred

had been employed two years earlier. A yearly capacity of one hundred and fifty

locomotives was claimed. It is doubtful if this production was achieved in any

one year, but one hundred were built in 1853. Few shops equated the Norris

Works in physical plant or production until after 1870. The factory area is now

the campus of the Community College of Philadelphia. The firm reached its peak

in 1857-58, after which time, the Norris family seems to have lost interest in

the business. Manufacturing quality and output fell during the Civil War and

the plant closed in 1866, but deliveries continued for a year or two.

The property lay idle until the adjacent Baldwin Locomotive Works—which had surpassed Norris as the largest locomotive builder in America—acquired the site in 1873. The Norris buildings stood until 1896 when part of the property was cleared for construction of the third U.S. Mint in Philadelphia. (Still standing, that building is now part of the Community College of Philadelphia.) Today, there is no trace of either the Norris or Baldwin factories in that part of downtown Philadelphia.

More information on the Norris Works may be found in the 1858 article by Edwin Freedley and in Wikipedia.

About The Hopkin

Thomas Project

Rev. October 2012