A HISTORY OF

THE

AMERICAN

LOCOMOTIVE

ITS DEVELOPMENT: 1830-1880

JOHN H. WHITE, Jr.

Dover Publications. Inc.

New York

Copyright 1968 by The Johns Hopkins Press.

This Dover edition, first published in 1979, is an

unabridged, slightly corrected republication of the work originally published

in 1968 under the title American Locomotives: An Engineering History, 1830 1880, by The Johns Hopkins Press, Baltimore. It

appears by special arrangement with The Johns Hopkins Press.

Ed. An excellent technical review of early engines - a valued addition to

any collection. Copied hereafter

are sections dealing with locomotives built during Hopkin Thomas' time; Garrett

& Eastwick, the Nonpariel, anthracite coal

utilization, chilled cast iron wheel construction, and drawings of

selected engines of the time. [J.

McV.]

The 0-4-0, 0-6-0, and 0-8-0

Locomotives

Grate Area And Heating Surface

Locomotive Types and Wheel Arrangements

THE 4 –

4 – 0

pp. 46 - 57

The 4-4-0,

variously called the American type or the standard eight-wheel engine, was the

most popular wheel arrangement in nineteenth-century America.9 It succeeded because it met every

requirement of early United States railroads. It was well suited to al1

service, including passenger, freight, and switching. It was flexible, having

three-point suspension and a leading truck, and it operated wel1 on uneven

tracks. It was simple, having relatively few parts, which made it easy to

repair. It was low in first cost, and it was relatively powerful because of its

four connected driving wheels. Finally, it was the national engine, a machine without

peer in this country, because it answered every need.

The 4-4-0 was originated by Henry R. Campbell, a

native of Philadelphia and long-time associate of M. W. Baldwin, while he was

chief engineer of the Philadelphia, Germantown, and Norristown Railway.

Campbell secured a patent on February 5, 1836, and began work on his engine a

month later. The machine was built in Philadelphia at James Brook's shop. When

finished in May, 1837, it was a giant for the times as indicated by the

following dimensions:10

|

Cylinders |

14" by 16" |

|

Wheels |

54" in diameter |

|

Weight |

12 tons (long tons) |

|

Heating surface |

723 sq. ft. |

|

Steam pressure |

90 lbs. |

It was estimated that at about 15 miles per hour

the engine could pull a 450 ton train on level ground. This represented a 63

per cent gain in tractive force over the standard Baldwin 4 2-0. Campbel1 had

succeeded in producing a machine with increased power over the six wheeler, but

otherwise the engine was not successful. Its suspension was too rigid and it

was prone to derail.11

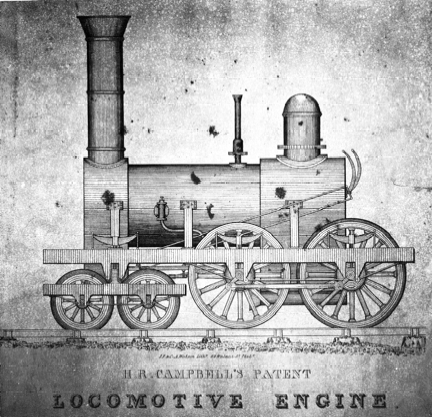

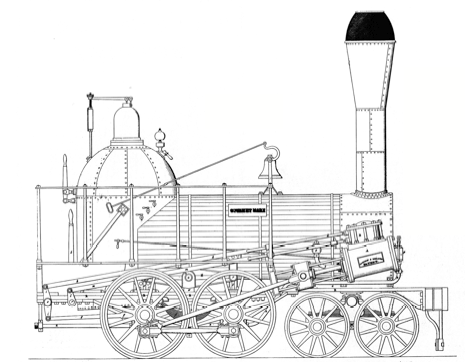

A contemporary engraving of Campbell's

eight-wheel engine was printed in the American Railroad Journal for July 30,

1836. This cut was undoubtedly reproduced from a large engraving issued at the

time by Campbel1 to advertise his patent (see Fig. 19).

Fig 19. Campbell's

patented eight-wheel locomotive. A machine similar to the one in this

illustration was built in 1836 or 1837; it was the first 4~4~0 constructed.

A limited amount of evidence has been uncovered

indicating that Campbel1 sought to enforce his patent. He threatened to

prosecute Garrett and Eastwick for infringement in 1837.12 Several years later the minute books of the

Philadelphia and Reading Railroad refer to a dispute with H. R. Campbell for

the unlicensed use of his patent for several new eight-wheel engines built by

the Locks and Canals machine shop.l3 Settlement was made for forty shares of Reading

stock. Baldwin was reported to have purchased the right to use Campbell's

patent in 1845.14

The extent of Campbell's success in capitalizing on his patent is unknown, but

even the collection of a trifling fee for each engine built on this plan would

have resulted in a fortune for the patentee, considering the popularity of the

4-4-0 during the life of the patent.

At about the same time that Campbell was testing

his first engine, two other Philadelphians, Eastwick and Harrison, built an

eight-wheel engine named the Hercules. Completed early in 1837 for the Beaver Meadow

Railroad, it was surely the second 4-4 0 built. Little is known of its

mechanical particulars except that it weighed 15 tons. It had a flexible

running gear and, unlike Campbell's engine, could adapt itself to uneven,

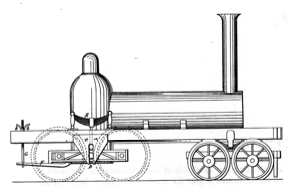

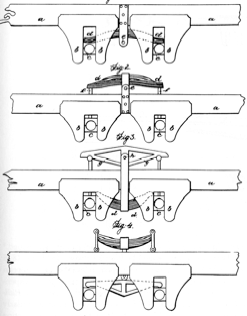

tracks. The Hercules was fitted with a separate "truck frame, after a design of Eastwick (see figure

below), which equalized two driving axles. Eastwick's equalizer was not

entirely satisfactory and was succeeded a year later by Harrison's equalizing

lever. The equalizing lever, which allowed three-point suspension, was possibly

the most important American contribution to locomotive design. More will be

said on this subject in section on suspension.

Andrew Eastwick's patent

of 1837 was devised to improve the suspension of the new 4-4-0 locomotive. The

design was not successful, however, and was superseded by Harrison's plan.

Eastwick's and Harrison's perfection of the 4-4

0 did immediately bring a general adoption of this style of engine For the next

two years they were the only builders to offer 4-4-0's. Norris, probably the

next builder to produce eight wheelers, built his first in 1839. Rogers, Locks

and Canals, and Newcastle followed, building their first 4-4-0's in 1840.15 Even so, production was

limited; only about twenty 4-4-0s were in service by 1840.

After 1840 the production of 4-4-0's increased

sharply. The eight wheeler had proved itself a practical road engine with

greater capacity than the 4-2-0 and was readily accepted as the new national

type. Even Baldwin, a dedicated advocate of the 4-2-0, was finally forced in

1845 to build eight wheelers since few roads were purchasing six-wheel engines.

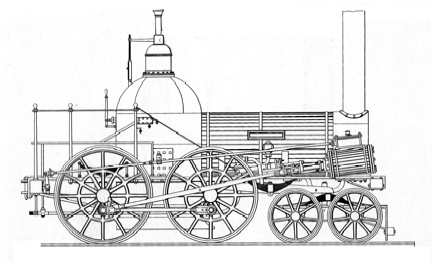

The typical 4-4-0 of the early 1840s was a

compact little machine of short wheel base which rarely weighed more than 12

tons. Such a machine is illustrated by the Rogers engine apparently built for

the Utica and Syracuse Railway, in Fig. 20. Another example is the Gowan and

Marx discussed at some length

later in this study. Nearly all of these early 4-4-0's were characterized by

the connection of the main rod to rear driving wheels.

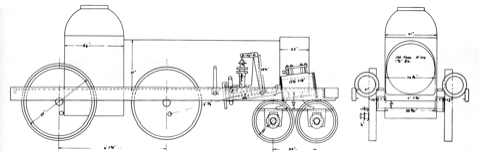

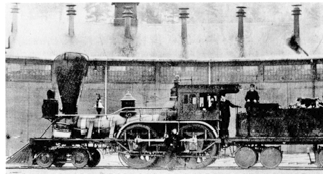

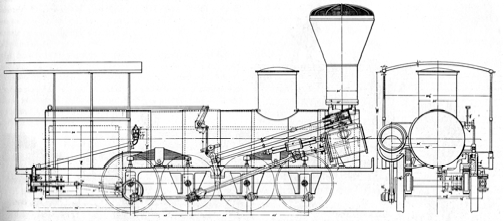

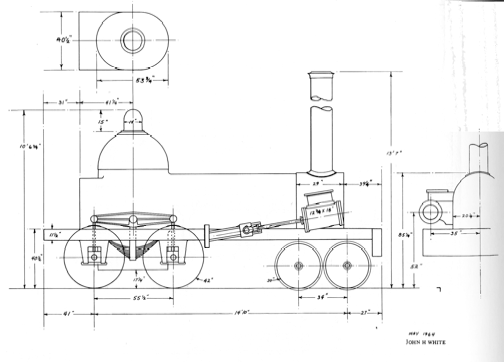

Fig. 20. A Roger's 4-4-0

of about 1843. Wheels, 60 in.; cylinders, 12 in. by 18 in.; weight, 11 tons.

The 4-4-0 took on a more familiar appearance in

the 1840's when the lengthened boiler resulted in the wider separation of the

truck and drivers. The cylinders were now so far from the rear drivers that the

main rod was commonly attached to the front drivers. Many significant changes

in general arrangement occurred during the mid-1840's; it is unfortunate that

no complete working drawings for any 4-4-0 of this period are known to exist.

There are, however, several fragmentary drawings for eight wheelers of this

period that worthy of consideration.

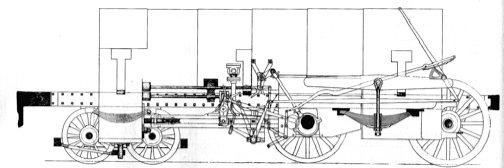

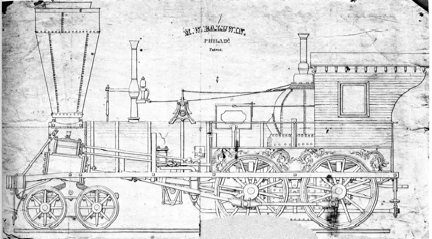

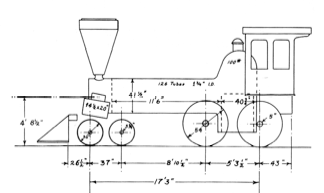

The earliest of these drawings, reproduced in

Fig. 21, is the Massachusetts and the Connecticut. Built in October, 18 by

Rogers, these engines are typical 4-4-0's of the period The drawing traced from

an original Rogers order book is regrettably sketchy. The other three drawings

of 4-4-0's of the 1840s, Figs. 22-24, while more complete, show more atypical

designs. The Wm. H. Watson (Fig. 22) was an unusually large locomotive for its

time, weighing nearly 27 tons, and embodied several unusual, though not

freakish, design features. The engine was built in the Baltimore shops of the

Baltimore and Susquehanna Railroad to the design of James Millholland.

completed in March, 1847, it was used for heavy freight service. The inside

cylinders were not unusual, but the massive cast-iron crank axle was a feature

decidedly peculiar to Millholland. The cylinders measured 18 inches by 18

inches; here again the fact that the stroke was equal to the diameter of the

cylinder was at variance with usual practice. The truck was also unusual since the

frame was outside the wheels and below the axles. The uooden outside frame was

rather antique for the period.

Fig. 21 The Massachusetts and the Connecticut,

built in 1846 by Rogers. and data copied from an original Rogers order

specification. Weight 18 tons.

Fig. 22. The Wm. H.

Watson, built in 1847 by James Millholland in the Baltimore and Susquehanna

Railroad shops.

The Mohawk (see Fig. 23), while more conventional

than the Watson, was also quite a large machine even for the late 1840's. It

weighed 22 tons and had 15-inch by 25-inch cylinders and 60-inch wheels. The

Practical Mechanics Journal for January, 1850, noted that the engine was

rebuilt by Walter McQueen in the Albany and Schenectady Railroad shops. The

rebuilding apparently took place in 1847 or 1848, but no evidence is available

on the original builder nor on the exact nature of McQueen's alterations. The

Mohawk had one remarkable design feature, the cylinder saddle, which generally

is not credited until the early 1850's.

Fig. 23. The Mohawk of

the Albany and Schenectady Railroad as rebuilt by Walter McQueen in the company

shops in 1847 or 1848.

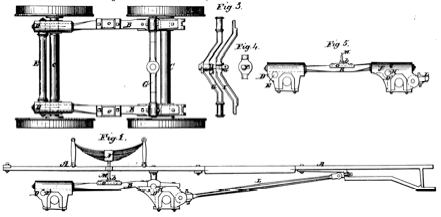

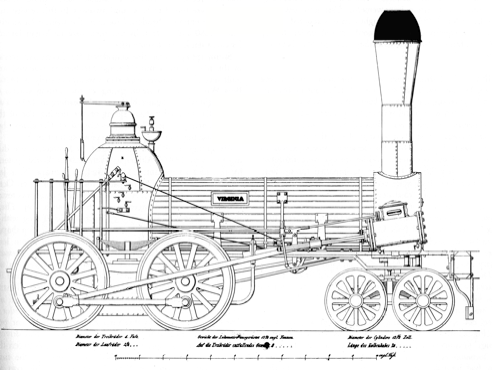

The final 4-4-0 of this group is the Tioga (Fig. 24) built by Baldwin

for the New York and Erie in December, 1848. It was a six-foot-gauge engine and

was therefore large for the period. It weighed slightly over 28 tons and had

cylinders 16-1/2 inches by 20 inches with 72-inch drivers. Except for its size

it is probably a fair representative of Baldwin's standard practice of the late

1840's. The outside frame (note the heavy cast-iron pedestals) was not used

much in this country. The outside cranks (see Fig. 25) were necessary because

of the outside frame. Other mechanisms worthy of note are the double throttle

valves, the forward steam dome, and the separate cutoff. Baldwin built eight

engines on this plan for the Erie Railway between December, 1848, and June,

1849. They were among the last half-crank engines built by Baldwin.

Fig. 24. The Tioga,

built by Baldwin for the New York and Erie Railway in 1848. Six-foot gauge.

Fig. 25. The New York

and Erie's No. T, 13, built in 1848 by Swinburne. Shown as rebuilt with a

spread truck, link motion, and other minor modifications. Note the similarity

of this engine and the Tioga.

Generally, the development of the 4-4-0 between

1840 and 1850 was simply an enlargement of the machine as it was first

introduced. Boilers were set low, conforming to a near panic about high centers

of gravity, short wheel base trucks prevailed, and the Bury firebox and

hook-motion valve gears were standard. All of this was changed in the early

1850's. A "modern" machine emerged that revolutionized the industry

It combined several notable features such as spread leading trucks, Stephenson

link motion, and the wagon-top boiler.

Zerah Colburn, writing in 1860, believed that Thomas Rogers deserved

credit for the combination, though not for the invention of these features:

"Thomas Rogers . .

. may be fairly said to have done more for the modern American locomotive than

any of his contemporaries. In America the standard wood-burning engine of today

stands precisely where he had brought it in 1852, and where he left it at his

death in 1856."16

While not wishing to detract deserved praise

from Rogers, it should be noted that William S. Hudson became superintendent of

the Rogers works precisely when the first modern engines were built, in 1852.

In addition, in 1852 William Swinburrne, also from Paterson and formerly with

Rogers, built a locomotive named America that combined all the reforms credited

to Rogers. The question, then, is who was responsible for these

reforms—the proprietor, the superintendent, or some obscure draftsman?

Credit properly given or not, Rogers' new style of engine was rapidly adopted

so that by 1855 every progressive American builder was producing engines on the

"Rogers pattern." This pattern was little changed, except by an

increase in size, for the next 30 years. The New Jersey (Fig. 28) clearly

illustrates the "modern" style of eight wheeler introduced by Rogers

in 1852. The lithograph from which this illustration is taken is undated.

Rogers is known to have built four engines named New Jersey between 1852 and

1854. However, none of these had u heels as large as those indicated by the

lithograph.

Fig. 26 A Baldwin 4-4-0 of about 1848

Fig. 27. The Allegheny,

built by Baldwin for the Pennsylvania Railroad in 1850.

The American type continued unrivaled as a

general service engine through succeeding decades. Angus Sinclair claims it

reached its peak of popularity in 1870 when 85 per cent of the engines in

service were of this type.17 Sinclair's estimate might be somewhat

exaggerated, yet in 1872 4-4-0's accounted for 60 per cent of the Baldwin

work's production. The Master Mechanics Association concluded after comparing

all wheel arrangements that "the eight wheel engines do the same work at a

much less cost.'' 18

In the same report Wilson Eddy, master mechanic of the Boston and Albany,

attacked the "Mogul" and “Consolidation,'' saying, "They run

much harder, and with much more friction and more wear and tear of the track

than a common eight wheel engine."19 Eddy supported his contention in 1876 by

testing one of his remarkable eight wheelers known as "Eddy Clocks"

against a Rhode Island Mogul named the Brown.20 Except for wheel

arrangement the two engines were nearly identical in size, but the Adirondack,

Eddy's engine, had a firebox 6-1/2 inches wider than its rival because of Eddy's

clever use of a slate rail frame. The results of the test were a decided

triumph for the Adirondack which consumed $190 less fuel while doing the same

work as the Brown. Eddy's point was that a good American could do anything a

Mogul could, and do it cheaper! The actual point was that in the 1870's more

roads were finding the American too small for freight service.

The decline of the American type was rapid by

the mid 1880's. This is most noticeable in the decreasing number of new 4-4-0's

built. In 1884, 60 per cent of the new engines purchased were 4-4-0's.21 Two years later only

half of new construction was of this type, and by 1891 just over 14 percent was

of the American tvpe.22 The eight wheeler maintained its popularity for

passenger work into the early 1890's until heavy wooden vestibule coaches and

faster schedules proved too much for its limited capacity. By 1900 the 4-4-0

was an obsolete design. It continued to be built in very limited numbers as

late as 1945 when Baldwin turned out a tiny 33-ton 4-4-0 for the United of

Yucatan Railways.

It would be difficult to exaggerate the

importance of this single class of locomotive to the nineteenth-century

American railway. No other style of general purpose locomotive enjoyed a

greater popularity, and few proved as useful or satisfactory in performing the

work they were required to do.

9 The class name "American" was suggested for the 4-4-0 in the Railroad Gazette, April 27, 1872, p. 183. This is the earliest recorded instance of the term known to the author.

10 American Railroad Journal July 30, 1836, pp. 465-66; see also Railway and Locomotive Historical Society Bulletin, No. 35, for P Warner's excellent general history of the 4 4-0 locomotive.

11 Campbell's first 4-4-0 was later sold to the Long Island Railroad, according to a note in C. B. Stuart's Civil and Military Engineers (New York, 1871), p. 330. This is confirmed in part by a note in the Railway and Locomotive Historical Society Bulletin, No. 10 (p 12), which stated that a 4-4 0 named Chichester was acquired by the Long Island from H. R. Campbell in 1842. It is also claimed that the above locomotive was a Baldwin 4 2-0 rebuilt by Campbell.

12 American Railroad Journal, August 26, 1837, p. 534.

13 Minutes of the Philadelphia and Reading Railroad, January 21, 1843, in the files of the Reading G., Philadelphia, Pa.

14 The History of the Baldwin Locomotive Works (Philadelphia, 1923), p. 41.

15 M. N. Forney in his history of the Rogers Locomotive Works Locomotives and Locomotive Building (orig. pub. New York, 1886, 2nd ed., Berkeley, Calif., 1964), p. I7, incorrectly states that Rogers built his first 4-4-0 in 1844. This error has been repeated many times. Rogers built nearly twenty 4-4-0's between 1840 and 1844. The Oneida of the Syracuse and Utica Railroad, completed in June 1840, was probably his first.

16 Clark and Colburn, Recent Practice, p. 48. In its issue of October 20, 1855, the Railroad Advocate credited Rogers with the most advanced design

17 Sinclair, Locomotive Engine, p. 636.

18 American Railway Master Mechanics Association Annual Report, 1872, p. 171; hereafter cited as Master Mechanics Report.

19 Ibid., p. 130. 20 Ibid., p. 177.

21 National Car and Locomotive Builder, March, 1884, p. 30

22 Ibid., January, 1887, p. 12, and January, 1892, p. 10.

23 G. E. Sellers, "Early Engineering Reminiscences," American Machinist, September 12, 1885, p. 5.

THE 0-4-0, 0-6-0, AND

0-8-0

pp. 66 - 69

The four-wheel connected engine is the most

elementary wheel arrangement possible. Its history as a road engine is

extremely brief and accordingly will be treated briefly. Several of the British

imports, notably Stephenson's "Sampson" class, a few early American

products such as the West Point and De Witt Clinton, and the Baltimore and

Ohio's Grasshoppers were all intended for road service. Their limited power and

poor tracking soon reduced the 0-4-0 to switching service, however, after which

it played a minor role in locomotive development.

What would have been the first American 0-6-0

was ordered from Stephenson by the Baltimore and Ohio in 1829, but the machine

was not delivered, because it was lost at sea.35 The Nonpareil, built by

the Beaver Meadow Railroad in 1837 or 1838, was probably the first 0-6-0 constructed

in this country. Baldwin's

first flexible-beam truck engines, introduced in 1842, were 0-6-0's. They were

probably the most numerous machines of this wheel arrangement in the United

States during the early years of the 0-6-0's development. Between 1842 and

about 1864 some 200 were manufactured. Norris also produced six-wheel connected

engines; they built a number of 0-6-0's from the early 1840's through the

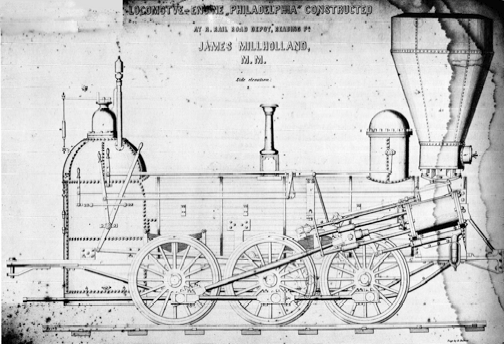

1850's. The Philadelphia (see below) is an example of a Norris six wheeler. A

number of powerful six-wheel freight engines were built between 1854 and 1856

by Rogers for the Buffalo and Erie, the Buffalo and State Line, and the

Lackawanna railroads. A lithograph was issued of one of these engines, the Volcano. This engine weighed 23

tons and had 16-inch by 22-inch cylinders and 54-inch drivers. The New Jersey

Locomotive and Machine Works and Danforth-Cooke also built engines (mainly for

the Lackawanna) on the same plan during the mid-1850's All 0-6-0's were

intended for slow freight traffic and were a minor wheel type on early American

railroads. Before 1870 is questionable if more than 300 were constructed in

this country. During the 1860's and 1870's they were entirely replaced by 2~0's

or 2-8-0's for road service and after that date were used only for switching.

The Philadelphia, shown

as remodeled by Millholland in 1848 or 1849.

The first eight-wheel connected engine was, like

the 0-6-0, built at an early date. The Camden and Amboy Railroad built an

eight-wheel engine, the Monster, between 1835 and 1838.36

An awkward machine, it seemed to favor marine

rather than railway engineering practices. It was not truly an 0-8-0, for spur

gears rather than connecting rods were used to couple the second and third

driving axle. The machine was indeed monster; it weighed about 18 tons and had

cylinders 18 inch by 30 inches. Four heavier engines were built on this design

in 1852 and 1854 for the Camden and Amboy by the Trenton Locomotive Works.

Another was built by the Camden and Amboy in 1852, thus making a total of six

"monsters."

Ross Winans designed the next 0-8-0 in this

country after the original Monster. The American Railroad Journal of March 15,

1841, describes this engine as weighing 19-1/2 tons with cylinders 14-1/4

inches by 24 inches. The machine was apparently new at the time and was

undergoing tests on the Baltimore and Ohio. In September, 1841, the Western

Railroad (Massachusetts) purchased this or an identical engine from Winans and

named it the Maryland. The Maryland had a vertical boiler and spur gear drive

and was in general arrangement an enlargement of Winans' earlier

"Crab" engines. Winans and Baldwin each built three more eight-wheel

engines of this design in 184142. The Western Railroad found them

unsatisfactory and all were retired by about 1850.

The Baltimore and Ohio found the 0-8-0 well

suited to its heavy coal traffic and became the largest single user of eight

wheel connected engines in the nineteenth century. Between 1844 and 1846 the

road received twelve locomotives from Winans, which, except for horizontal

boilers, were identical to those of the Western Railroad. These curious

machines became known as "Mud Diggers." A thirteenth "Mud

Digger" was built in the company's shop in 1847. In 1847 Winans materially

improved his eight-wheel engines by eliminating the gear drive and making a

direct connection to the driving wheels. Four machines were built on this

reformed plan for the Reading in 1847.

The following year the Baltimore and Ohio

purchased Winans' first "Camel" locomotive. This machine was the

primogenitor of the most famous class of 0 8-0's built in this country.

Designed for coal-burning and heavy traffic, some two or three hundred were

used successfully by several roads, despite several design defects. The Camel's

history is more fully discussed later.

In addition to Winans products, the Baltimore

and Ohio built and purchased 0-8-0's from other builders. An example of one of

the company-built eight wheelers is the unidentified machine shown in Fig. 34.

Note the similarity of this drawing to the Hero (Fig. 35), designed by Thatcher

Perkins in 1848. In 1865 Perkins designed an improved 0 8-0 that was intended

to supplement the Baltimore and Ohio's aging fleet of Camels. Twenty-four

Perkins 0-8-0's were built. They represent the final example of this wheel

arrangement designed for road service.

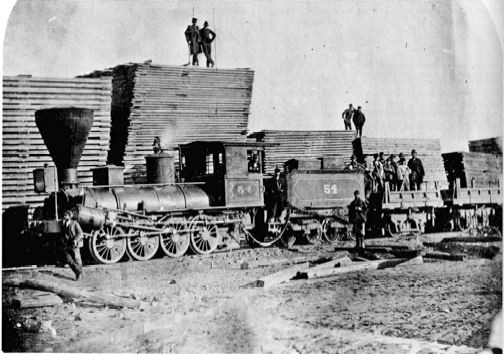

Fig. 34. An eight-wheel

connected locomotive of the Baltimore and Ohio Railroad. An exact

identification cannot be made (it may be only a design study), but its date of about

1848 is certain.

Fig. 35. The Baltimore

and Ohio's Hero, built by Thatcher Perkins at the company shops in 1848. This

photograph was taken in 1867. The engine was rebuilt in 1857, but the exact

alterations made are not known.

Aside from the Baltimore and Ohio and Winans,

Baldwin was the only other major figure associated with the 0-8-0. In 1846 he

built his first 0-8-0, which, like the 0-6-0, was a flexible-beam truck engine.

Subsequently, Baldwin built about three hundred 0-8-0's, ending production of

this design in 1866.

At best, six or seven hundred eight-wheel

connected engines were constructed in this country before 1870. Their use was

restricted to a few roads and their part in the early development of American

locomotives was accordingly minor.

35 C. F. D. Marshall, A History of the Railway Locomotive Engine Down to the Year 1831 (London, 1953), p. 145.

36 In his report of 1838 J. Knight described the Monster as nearly completed.

FUEL

pp. 86 - 90

COAL-BURNING

Compared to coal, wood is a bulky, primitive

fuel with a low calorific value. In the nineteenth century one ton of soft coal

was considered equal to 13/4 cords of wood, or, roughly figuring wood at 3,000

pounds per cord, 2,000 pounds of coal equaled 5,250 pounds of wood.l9 While these figures are

not exact, the greater heating value of coal over wood was well understood by

engineers at the beginning of the railroad era. Contrary to present erroneous

beliefs that wood was the only fuel considered at the time, a surprising number

of our first railways initially experimented with coal-burning locomotives,

turning to wood only as a last resort. In 1828 the Delaware and Hudson planned

to use coal-burning engines for two reasons: one, it was a coal carrier; two,

the several locomotives imported for that service—the Stourbridge

Lion among them— were

copied from British colliery locomotives, which had always burned coal. The

failure of this pioneering steam railroad venture was attributable to weak

tracks rather than to the use of coal as fuel. The Baltimore and Ohio's first

experimental locomotive, the Tom Thumb, burned anthracite successfully; the

road then specified that all engines entering its 1831 locomotive contest must

use the same fuel. In later years this road was a leader in the development and

use of coal-burning locomotives. S. H. Long, the renowned civil engineer and

bridge designer, built a number of anthracite-burning locomotives in the early

1830's. His locomotives were tested on the Philadelphia and Columbia, the

Newcastle and Frenchtown, and the Boston and Providence Railroads. All were

unique and highly individual mechanisms, but none was considered a success.20 Another engineer

usually remembered for his civil-engineering contributions, John B. Jervis, a

contemporary of S. H. Long, conducted some experiments with coal-burning

locomotives on the Mohawk and Hudson Railroad. Jervis carried over this idea

from his previous employer, the Delaware and Hudson Canal Company. The De Witt

Clinton, before entering regular service, was fired with "Lackawanna

Coal" in July, 183l.21 The test, though unsuccessful, did not

discourage Jervis from having another hard-coal burner constructed a year

later. This engine, the Experiment, worked no better than the De Wit Clinton

and was soon fitted with a wood-burning firebox. The Camden and Amboy Railroad

is also known to have been a early investigator of coal-burning engines. A good

deal of th interest is attributable to members of the Stevens family of

Hoboken, New Jersey, who were not only chief promoters of the railroad but also

early advocates of coal-burning steam ships. The road may have experimented

with coal-burning as early as 1833, as indicated by the wide firebox boiler

engine, but it is definitely known that the eight-wheel freight locomotive the

Monster, built between 1836 and 1838 at the company shops, was intended for

coal-burning.22

The road did not make a wholesale conversion to coal as a result of this

experiment, but other hard-coal engines were placed on the road in the late 1840's.

Of the several early attempts at coal-burning,

only two small anthracite roads in Pennsylvania, the Beaver Meadow and the

Hazleton, completely rejected wood. Both lines ran slow coal trains with

continuous runs of only 14 miles; thus there was an opportunity to rekindle and

otherwise nurse the engines along. Of course, this restricted manner of

operation was not practical for an ordinary railroad where passenger and

merchandise trains could not be expected to put up with delays occasioned by a

dull fire.23

Obviously the early attempts to introduce

coal-burning locomotives were a failure. A small number of "coalers"

continued to work, but, in general, early American roads were powered almost

exclusively by wood-burners. The chief difficulty was an inability to burn

coal. The blame for this falls directly on the type of coal available. Only

anthracite, or as it was first known, "stone coal," was mined in this

country before about 1840. It was a difficult fuel to burn, particularly in the

small locomotive fireboxes of that time. In addition, it was a slow-burning

fuel and was therefore particularly unsuited to the needs of the locomotive,

where rapid combustion was essential for a rapid production of steam. Had soft

coal been more commonly available in the 1830's, it is likely that successful

coal-burners would have been developed many years earlier.

The high price and limited supply of coal in

this period were other factors that discouraged an early introduction of coal

burning locomotives. Coal cost from $7.00 to $10.00 per ton in the 1830's.24 The big mines were

located in eastern and central Pennsylvania. Transportation costs considerably

boosted the price per ton for roads outside this area. As other coal fields

opened, particularly the Maryland, West Virginia, and southern Illinois

deposits, railroads in these areas were encouraged to adopt coal. But few of

these fields were in production before 1850; some were not in full operation

until many years later. Anthracite fields, which had been commercially worked

before any locomotives were employed in this country, did not achieve large

production until after 1840. Only after that time did coal become an important

American fuel.25

Industry, in general, was slow to adopt coal; thus, railroads were not alone in

their slow acceptance of this fuel.26 As production in the old fields grew, new

fields opened, and railroads could reach the mines and offer cheap

transportation; coal prices accordingly showed a steady decline as the

nineteenth century passed. By the mid-1850's coal was down to about $3.00 per

ton, and in 1862 the Baltimore and Ohio was able to get coal at 75 cents a ton

because of the many mines along its route. It was this decline in coal prices,

rather than the dramatic increase in wood prices, that brought about the great

conversion in locomotive fuel.

To return to examples of railroads making early

use of coal for locomotive fuel, no such account would be complete without reference

to the Baltimore and Ohio Railroad. This company showed a strong interest in

coal burning from its earliest years and was the only major American line to

operate coal burning locomotives continuously in the last century. Following

the first experimental locomotives in 1831, a class of coal-burning engines

with vertical boilers was perfected for freight service. In later years the

road continued to build or purchase new designs of coal-burning freight engines

but turned to woodburners for passenger service in the mid-1830's. Before 1840

anthracite was imported from Pennsylvania at $8.00 a ton.27 After the road reached

the soft-coal fields of western Maryland in 1840, bituminous coal was adopted.

In the next year, half of the road's power burned coal exclusively while a few

engines burned a mixture of wood and coal. A large number of eight-wheel,

coal-burning freight locomotives were purchased during the next several years.

Passenger trains were handled by wood-burners until the mid-1850's when new tests

were made with coke and coal. In 1858, 14 of 34 passenger engines were

converted to coal or coke. By November, 1859, all 235 locomotives were

coal-burning except for one freight engine and ten old light machines.28

The Philadelphia and Reading was another road

obviously interested in coal-burning locomotives because of the immense coal

traffic passing over its line. The original minutes of the Board of Managers

revealed the earnest desire of the Reading's management to adopt coal as

expressed in the following resolution dated April 13, 1835: "Resolved that

this board deem it of the utmost importance that the locomotive engines to be

constructed for this Company be built with a view to the exclusive use of

anthracite as fuel." The road's third locomotive, the Delaware, delivered

by Winans in 1837, was a coal-burner but it was not a success and was abandoned

in 1845. The Gowan and Marx, also intended for hard coal, was converted to a

wood-burner not long after entering service in 1839. Discouraged by these and

undoubtedly other unrecorded failures, the Reading abandoned further attempts

at coal-burning until 1847. In that year a mechanical monstrosity named the

Novelty was built in the company shops after a patented design of G. A.

Nicolls. The boiler was carried on a separate eight-wheel car; the flexible

pipe necessary for carrying steam to the locomotive leaked. This and other

complex auxiliary apparatus were devised by Nicolls. Predictably the engine was

a failure. In the same year Winans delivered several eight-wheel connected

engines of a more conventional design, but they were not notable successes.

This slow beginning was carried forward by James Millholland, who after an

unpromising series of experiments perfected a practical anthracite firebox by 1856.

By 1859 the road was virtually all coal-burning.

In New England, as already indicated, slower

progress was made. The great distance from the coal fields kept prices high.

Coupled with this was the resistance of many old-line managers to innovations.

One exception to this trend was George S. Griggs, master mechanic of the Boston

and Providence Railroad. Griggs was associated with the road when S. H. Long's

anthracite engines were purchased in the 1830's. While these engines failed as

coal-burners, Griggs was not prejudiced by. their poor performance. In 1856 and

1857 he initiated new tests and in the process developed the brick arch and

diamond stack, both of which were important contributions to coal burning. By

1860 the road was said to be powered almost entirely by coalburners.29 This statement was

somewhat premature, for, according to the road's annual reports, wood-burners

were in service as late as 1874 or 1875.

In the Middle Atlantic states the Philadelphia,

Wilmington and Baltimore Railroad was an early convert to coal-burning. In 1841

soft coal was used but it was abandoned after only six months.30 When interest in

coal-burning was revived, the road made the mistake of turning to freak firebox

designs. In 1856 a Taunton-built engine, the Essex, with a Dimpfel boiler, was

placed in service. This machine and the several that followed were only

moderately successful. Conventional coal-burning engines were acquired and by

1862 the road's annual report. stated: "Coal burning in locomotives is no

longer an expert meet, but a well established fact and a decided economy."

Three years later all but seven main-line engines were fueled with coal.31

The fuel question followed a similar pattern in

the Midwest. The Chicago, Burlington and Quincy was one of the first midwestern

railroads to convert. It acquired its first coal-burner in 1855 after reaching

the southern Illinois coal fields. The next year, eleven coal engines were in

service; in 1859 twenty-five were on the road. The conversion was accelerated

by the purchase of coal mines so that by 1868 all of its engines were burning

coal. The Illinois Central began experiments with coal-burning locomotives in

1855. At first, poor local coal dampened prospects for an early conversion,

but, despite this difficulty, over half of the road's engines were coal-burners

by 1861. Five years later only 5 of 151 engines were wood-burners. Not all

railroads in this area found native coal satisfactory, and the Galena and

Chicago Union's report of 1863, while admitting that wood prices were

prohibitive, stated that coal was no ready solution.

Illinois coal was inferior because it contained

a high percentage of sulphur. Until more precise methods of processing were

developed, eastern coal was imported. In later years Illinois coal was

successfully employed, despite early complaints regarding its quality, and

western roads kept pace with the other major lines in abandoning wood.

The conversion of locomotive fuel from wood to

coal may be summarized as follows: The early interest in coal-burning resulted

in no substantial use; only a few coal-field lines regularly employed this

fuel. By the 1850's a renewed and substantial interest in coal-burning was

thwarted by the mistaken belief that revolutionary changes in firebox design were

necessary. It was quickly established that fireboxes of ordinary construction

were capable of successful coal-burning, and by the late 1850's several

important railroads had adopted coal. During the 1860's and 1870's coal was

accepted as the best fuel for locomotives, and all major railroads began

abandoning wood. By 1880 more than 90 per cent of railway fuel was coal.32

During the next two decades all American

railroads, except for a few obscure lines, converted to coal.

Compared to coal and wood, the other fuels

considered for locomotive use are of only passing importance. Coke was the most

important alternate tested, but its use was extremely limited. As late as 1850

an English technical writer observing American practice stated: "The use

of coke is nowhere resorted to. Its expense would make it inadmissible; and in

a country so thinly inhabited, the smoke proceeding from coal or wood is not

objected to."33

From this comment it can be understood that coke was the required fuel in

England because of the smoke nuisance of coal and wood. Coal was adopted in

that country during the period that American railroads changed from wood to

coal. To turn to the use of coke in the United States, one of the few lines to

use the fuel was the Baltimore and Ohio Railroad. In 1854 two passenger

locomotives were tested with coke; the results were encouraging for, although

it was more expensive than "raw coal," no sooty smoke was given off.34 The road's 1857 report

noted the construction of six new coke-burning passenger engines. The greater

cost of coke ($2.00 per ton compared to 75 cents for a ton of coal) discouraged

continuance of coke-burning locomotives after about 1862. While coke was for a

short time considered ideal for passenger service because of its clean burning,

it was soon discovered that careful firing of coal could eliminate a good

portion of the smoke. To encourage this practice the Illinois Central placed

the following notice in the cabs of its passenger locomotives.35

Machinery

Department, Illinois Central Railroad.

Weldon,

May 7th, 1868.

SPECIAL

INSTRUCTIONS TO PASSENGER ENGINEERS.

To prevent

your engine throwing out large quantities of smoke, you will see that your

fireman is very particular in the manner of firing, and that he observes

closely the following rules:

Do not throw more than

two shovels of coal at one time, and scatter it well over the grates.

Keep the fire as nearby

uniform as possible.

Keep the coal in your

tender dampened, so that the dust from it will not be blown back upon the train.

Whenever the steam is shut off, the blower should be used lightly.

The air openings around

the furnace and in the door should be kept open as much as possible.

Much of the annoyance

from smoke and coal dust will be prevented and a large saving in fuel effected

by attention to the above rules.

S. J. HAYES

Superintendent of

Machinery.

Petroleum was considered as a fuel surprisingly

early, but its short supply and high price prevented any extensive use in this

country during the nineteenth century. As early as 1864 the United States Navy

experimented with oil-fired boilers, and suggestions were made at the time for

oil as a locomotive fuel.36 Ten years later an old engine of the Boston and

Providence was altered to burn coal oil, but the experiment ended in failure

after a twenty mile run when oil leaks set the engine on fire.37 The first regular use of petroleum for

locomotive fuel developed in Russia. Thomas Urquhart, superintendent of the

Grazi Tsaritzin Railway, began the use of fuel oil in 1882; by 1885, 143

engines on the line were using this fuel.33

There was, however, little interest in oil-fire locomotives in the United

States until the great western oil fields produced large surpluses during the

early 1900's.

17 Master Mechanics Report, 1872, p. 49.

18 Railway and Locomotive Historical Society, Special Bulletin, "Vermont Central," 1942.

19 Colburn and Holley, The Permanent Way, p. 8. Marks's Mechanical Engineers Handbook, pp. 711 and 799, shows 1 pound coal = 13,000 B.T.U..; 1 pound wood = 5,800 B.T.U. R. H. Thurston's A Manual of Steam Boilers (New York, 1896), p. 160, offered a different ratio, stating that 1 cord of well-seasoned yellow pine equaled only 1/2 ton of good coal.

20 Colonel Long's attempts at locomotive building are covered in Railway and Locomotive Historical Society Bulletin, Nos. 79 and 101. Between 1826 and 1833 Long secured several patents for locomotive boilers and running gears.

21 W, H. Brown, The History of the First Locomotive in America (rev. ed.; New York, 1874), p. 178, reproduced a notice from the Albany Argus, July 25, 1831.

22 Master Mechanics Report, 1885.

23 Reports on the Beaver Meadow and Hazleton coal-burning locomotives appear in the Journal of the Franklin Institute, June, 1847, and in G. W. Whistler, Jr.'s Report upon the Use of Anthracite Coal in Locomotive Engines on the Reading Rail Road (Baltimore 1849), pp. 27-28.

24 Knight and Latrobe, Locomotive Engines, note coal prices at this rate on several eastern roads.

25 H. N. Eavenson, First Century and a Quarter of the American Coal Industry (Pittsburgh, 1942).

26 The iron industry showed little interest in replacing charcoal with coke until after 1850; the slow conversion of western riverboats to coal is discussed in Louis C. Hunter's Steamboats on the Western Rivers. One of the few important industries to make an early conversion to coal was Hudson River and ocean steamers.

27 Whistler, Anthracite Coal, p. 21.

28 Letter of Henry Tyson to J. W. Garrett (president, Baltimore and Ohio Railroad), November 9, 1859.

29 American Railway Times, January 28, 1860.

30 American Railway Times, March 9, 1861.

31 For more data on the Philadelphia, Wilmington and Baltimore's conversion to coal-burning, see Railway and Locomotive Historical Society Bulletin, No. 21.

32 The 1880 census lists fuel consumed by individual lines but gives totals for major geographic sections only. The author's totals are 1,388,723 cords of wood; 9,531,080 tons of coal; ninety per cent is en approximate percentage based on 1 ton's equaling 1-1/2 cords.

33 Dionysius Lardner, Railway Economy (New York and London, 1850), p. 336.

34 Mendes Cohen, Report on Coke and Coal Used with Passenger Trains, on the Baltimore and Ohio Railroad (Baltimore, 1854).

35 Locomotive Engineering, May, 1899, p. 238.

36 American Railway Times, January, 1864, p. 14. 37 Boston and Providence Annual Report, 1874. 38 Institution of Locomotive Engineers Journal, 1952, pp. 42 see also Eugene McAuliffe, Railway Fuel (New York, 1927).

COMPONENTS

BOILER TUBES

pp. 99 - 100

The boiler waist contains a large number of

small-diameter fire tubes intended to increase heating surface and promote

steam-making capacity. The tubes are parallel to one another and connect the

fire- and smoke-boxes.

The earliest American locomotive boilers

invariably contained 100~150 copper tubes varying from one and a half to one

and three-quarters inches in diameter. Copper was easy to fabricate Thin copper

sheets, generally less than one-eighth of .an inch thick, were cut into strips,

the strips were rolled and lap-welded into tubes. In about 1860 seamless copper

tubes were introduced, but lap-welded tubes continued to be manufactured for

many years. The soft metal was easily flanged and a good steam-tight joint

could be made at the tube sheets with a simple calking tool. When the joint

worked itself loose during expansion and contraction, it was readily re-flanged

and made good for many more miles of use. Copper tubes gave remarkably good

service. The Pittsburgh, Fort Wayne and Columbus Railroad reported twenty years

of service, while the Little Miami Railroad realized 150,000-200,000 miles when

copper tubes were used in wood-burning engines.l6

Brass tubes were first used in this country in

1851.17 Their use spread fairly

rapidly so that within the next four years 800 locomotives were fitted with

brass tubes.l8

Greater cost and difficulty in flanging (brass being less ductile than copper) prevented

them from superseding copper tubes in America; they were immensely popular in

Britain, however.

Iron tubes were used as early as 1831 by the

Baltimore and Ohio and were taken up at an early period by the other roads

operating coal-burning locomotives. Iron tubes were difficult to flange, but

they were considerably cheaper and more durable than copper tubes. The American

Railway Review stated that copper tubes cost $1,000 per locomotive compared to

$400 for iron tubes.19 In some cases, copper ends were welded on for

easy flanging. Iron tubes were fabricated from sheet stock and the joint was

brazed. The ability of iron to withstand the erosive action of fly ash led to

its adoption for coal-burning engines. After 1860 iron tubes were on the ascent

and the use of copper and brass became increasingly rare as the century closed.

Experiments with steel tubes began in the early

1860's. By 1863 a British supplier, Russell and Howells, could report the use

of steel tubes by several important railroads. These included the Camden and

Amboy, Erie, Hudson River, and other eastern lines.20 Despite this initial

interest, however few roads adopted steel for locomotive tubes. In 1876 it was

reported that lap-welded iron tubes were the general rule; steel tubes were not

considered to be worth the extra cost.21 As late as 1892 Meyer concurred with this

observation, stating steel was only "sometimes" used for tubes.22

Steel did not rival iron for tubes during the

nineteenth century, even though it surpassed its competitor years earlier in

boiler and firebox manufacture. It was difficult and expensive to weld. Because

it was stronger than iron, very thin steel tubes could be constructed. These

proved to be better heat exchangers because there was less wall thickness to act

as insulation. Yet the difficulties of welding and higher costs prevented the

general adoption of steel tubes until about 1900 when cheap, seamless steel

tubes were introduced.

Tube diameter remained remarkably unchanged

throughout the last century. One and three-quarter inch tubes were standard up

until 1860 when a movement began for two-inch diameters. With minor exceptions,

this size was popular th the 1890's.

16 Master Mechanics Report, 1870, p. 105; 1872, p. 148.

17 Colburn, Locomotive Engineering, p. 83.

18 Railroad Advocate, May 5, 18 5 5, p. 3.

19 American Railway Review, July 4, 1861, p. 405.

20 A circular issued by Russell and Howells, in the M. W. Baldwin Letters (Historical Society of Pennsylvania, Philadelphia, Pa.); hereafter cited as Baldwin Letters.

21 Institution of Civil Engineers, Proceedings, Vol. 5 3 (1878), p. 5 1.

22 Meyer, Modern Locomotive Construction, p. 437.

FIREBOX CONSTRUCTION

pp. 102 – 105

The major patterns of fireboxes have already

been discussed in the opening section on boilers. However, the construction and

material of this structure require further explanation. The firebox, known as

the heart of the boiler, is a box within a box. The space between the inner and

outer box is filled with water. This water space partially insulates the inner

firebox plates from the destructive action of the fire. In wood-burning engines

the water spaces were 2 inches wide or less because of the relatively low heat.

Coal-burners, developing more intense heat, were built with 3- or 31/2-inch

water spaces. The inner and outer firebox plates were held parallel by stay

bolts usually set on 5- to 6-inch centers. These bolts were threaded and

riveted at both ends for security and steam-tightness. Robert Stephenson used

this style of construction on the Rocket in 1829 and it remained in use well

into the twentieth century. Hollow stay bolts were used by F. P. Dimpfel for

stationary boilers as early as 1839.35 Their introduction to locomotive practice is

uncertain, but hollow stay bolts were recommended by the master mechanics in

their report of 1872 and were apparently in regular use before that time.

The crown sheet or top-flat plate of the firebox

required support to prevent its collapse. Flat, iron bars called crown bars

were used for this purpose. Five to twenty such bars, depending on the size of

the crown sheet, were used. They were set on edge and riveted or bolted to the

crown sheet, thus forming a truss. Only the ends of these bars rested on the

top of the firebox. Washers were inserted between the bar and sheet at each

rivet so that the contact between these two parts was held to a minimum. This

was done so that as much of the crown sheet as possible would be covered with water

to prevent its burning out. Before 1860 crown bars were fastened transversely

or longitudinally, depending on the preferences of the designer. After the

introduction of coal-burning, longer fireboxes prevailed and crown bars were

invariably placed in a transverse position.

An ordinary crown bar was a thick (2 inches wide

by 5 inches deep) piece of iron with a hole drilled through for riveting.

However, double crown bars were used in the 1840's (and possibly earlier) as

shown by the Winans 4-4-0 below. This form of construction called for two thin

bars set close together. The rivets or bolts passed between the bars, thus

eliminating the labor of boring holes through the bar.

Detail drawing of a

4-4-0 built by Ross Winans in about 1845.

Wrought iron was used universally for crown

bars. The only variant from this rule was Norris' disastrous experiment with

cast-iron crown bars in the early 1840's. The failure of cast iron for this use

is illustrated by the explosion of the locomotive Richmond.

Stay bolts were a second method of supporting

the crown sheet. These bolts, much like those already described for the firebox

side sheets, were longer but were similarly attached to the inner and outer

sheets of the firebox. Stephenson used this style of construction in 1829 on

the Rocket but abandoned it almost immediately for simpler and cheaper

crown-bar construction. Isaac Dripps built a number of locomotive boilers,

beginning in the 1830's with X-braces or "crow's feet" in place of crown

bars. This method was similar to stay-bolt construction but received little or

no attention apart from the Camden and Amboy Railroad's limited use.36

In 1847 or 1848 Dripps designed a slope-backed

firebox with a combination of crown bars and stay bolts to support the crown

sheet. Several Crampton engines were built for the Camden and Amboy Railroad in

the next few years with this style of boiler. Soon thereafter Ross Winans and

James Millholland adopted Dripps's design but eliminated the crown bars. This

style of boiler, introduced in about 1852, was undoubtedly the first built in

this country to depend entirely on stay bolts for support of the crown sheet.

The earliest evidence of a conventional boiler so built, not a slope-backed

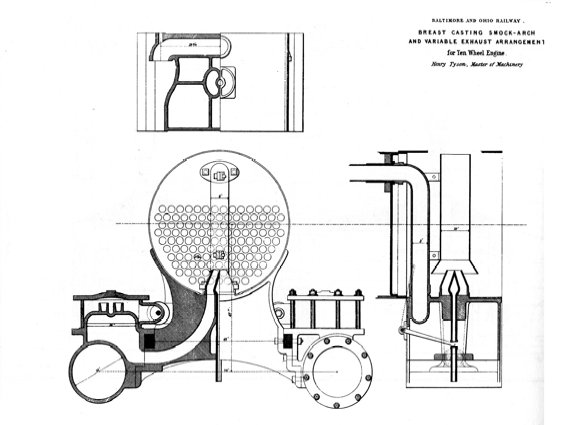

affair like Winans', is Henry Tyson's ten-wheeler design of 1856 (see figure

below). While stay-bolt crown sheet boilers made an early appearance, they did

not succeed the crown-bar boiler for many years, despite the several failings

of the latter. Crown bars restricted the free circulation of water over the

crown sheet and were a notorious collection place for scale. This not only

hampered the boiler's efficiency but hastened the burning out of the crown

sheet. Nevertheless, crown bars were considered the best and cheapest

construction plan until 1890. After that date their decline was swift. The

American Society of Civil Engineers in 1893 reported that crown bars were

losing favor. Four years later they were reported to be obsolete and rarely

used except on small locomotives.37

Detail of Tyson's

ten-wheel boiler. Note that crown bars are not used to support the crown sheet.

Several methods were used to seal the bottom of

the firebox water space. Stephenson used two angle irons (see the John

Bull,below), but this was a weak and complicated construction. Another method,

devised contemporaneously, was to flange the inner firebox sheet and rivet it

to the outer sheet. This simple, cheap form of construction was popular for

years. It is illustrated by the Lancaster, Fig. 106. The above methods were

superseded by the foundation ring, which by the 1850's was the approved plan

for sealing the water space. According to this plan, the inner and outer

firebox plates remained parallel and a thick, square iron bar was riveted

between them. See the Columbia, below, for this style of construction.

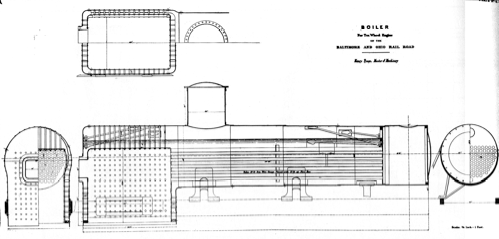

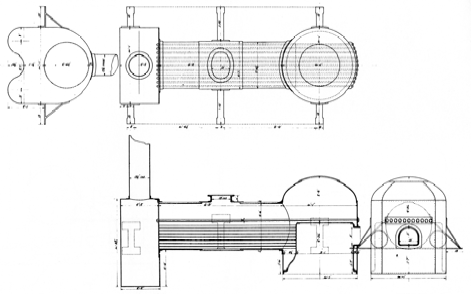

This boiler drawing is

believed to have been used in the construction of the John Bull.

Longitudinal section and

details of the Columbia

The bottom of the firebox water space was the

lowest part of the boiler and thus served as the collecting point for loose

scale and mud. One or more blow-off cocks, usually fitted to the rear of the

firebox, were used to eject all impurities that accumulated at that point.

Washout plugs or hand holes (also for cleaning) were located here.

Before 1860, copper and wrought iron were the

only materials used for firebox construction. At first iron was favored, but

its reedy texture and propensity to blister when under the direct action of

fire caused Stephenson to adopt copper for the firebox's inside sheets in about

1832. Early United States builders followed the British example, and copper

remained the favored material for this purpose until the 1860's. Because of

copper's low tensile strength and increased weakness when heated, it was

necessary to make firebox sheets very heavy. Rear tube sheets (the front sheet

of the firebox) were generally from two-thirds to three-quarters of an inch

thick if made of copper. The crown side and rear sheets were thinner, probably

from five sixteenths to three-eighths of an inch thick. A copper firebox (1,850

pounds) weighed nearly twice as much as an equivalent iron firebox (1,000

pounds) and cost nearly eight times as much ($540 versus $70).38 The higher cost was

justified in part by the longer life of a copper firebox when compared to that

of the iron. This was undoubtedly true when wood was the fuel, but soft copper

sheets were rapidly worn out by fly ash from coal. The Reading complained that

copper fireboxes wore out after only fourteen months service when fired with

anthracite coal.39

The Baltimore and Ohio found that the bituminous fly ash did not cut away

copper sheets so quickly and that about three and a half years' service could

be obtained.40

The Pennsylvania Railroad also found soft coal to be easy on copper plates and

used copper fireboxes for six years.41 This must be considered a record, although it

was not so-reported. Most roads found copper expensive and short-lived for coal

burning.

Thick copper sheets not only increased costs but

reduced efficiency. While copper might be supposed a better heat conductor than

iron, in practice, iron plates were found equally efficient in transmitting

heat because of their thinness. In effect, thick copper plates insulated the

water. This defect, added to the others already outlined, led to the general

abandonment of copper fireboxes in the United States during the 1860's. In 1870

the Baldwin Locomotive Works produced 280 locomotives. Only 6 of these had

copper fireboxes; the rest had fireboxes of steel.

Iron fireboxes were used as early as 1836 by the

Beaver Meadow Railroad for coal-burning locomotives. The Reading found this

material best suited for coal-burning engines when it began to convert to

anthracite in the late 1840's. Iron fireboxes should not be associated

exclusively with coal-burning, however. The Baltimore and Ohio preferred copper

fireboxes for their soft-coal engines, while many builders produced

wood-burners with iron fireboxes, largely because iron was cheaper than copper.

Thus, copper or iron was used for either fuel although copper was preferred for

wood engines before 1860. In 1860 Colburn stated that "the firebox is

always of iron" in American locomotives. This was another indication of

iron's triumph over copper.42

English plate was preferred by most American

locomotive builders. Millholland, however, was not satisfied with commercially

produced firebox iron, imported or domestic, and took a direct hand in its manufacture. He

procured the largest charcoal wrought-iron blooms available and worked them

over with a steam hammer in the Reading shops. After determining that the iron

was of the best quality, the blooms were sent out to a rolling mill for

manufacture. Exceptionally large plates, from 10 to 12 feet long and 6 feet 10

inches wide, were thus obtained.43

Iron had no sooner succeeded copper as the

favored firebox metal when it was challenged by steel. In 1860 Millholland was

reported to be using steel fireboxes.44 The Taunton Locomotive Company built a steel

firebox for the Erie Railway in the same year, which gave good service for ten

to thirteen years.45

Other builders began to offer steel fireboxes but these were not entirely

satisfactory. As with the earliest steel boilers, the plate used was too hard

and cracking was common. Softer alloys soon became available and by the

mid-1860's steel fireboxes were common. The Pennsylvania Railroad had 400

locomotives with steel fireboxes in 1869; some of these had been in service,

for six or more years.46 The success of the steel firebox is further

shown by the Baldwin records for 1870, which note that the vast majority of new

engines were so-built.

Not all master mechanics found steel

satisfactory for fire-boxes. Samuel Hayes respected steel's good qualities but

found iron more durable on the Illinois Central, where bad water: was the rule.47 Wilson Eddy was much

sharper in his dissent and claimed that steel firebox sheets became brittle

like "glass." He did not believe that steel was a miracle metal and

stated: that he would welcome more criticism of the "new-fangled"

material. Eddy's viewpoint was undoubtedly shared by other. old-time master

mechanics and was in line with his conservative approach (viz., his attacks on

Consolidation and Mogul locomotives) to the entire idea of locomotive reform.

Eddy's opinion carried little weight and most roads went ahead with the

conversion to steel fireboxes during the 1870's.

The rapid rise of steel for fireboxes must be

credited to its long life in such wearing service. With good water a steel

firebox would last 300,000 miles or about fifteen years.48 An iron firebox gave

only about three years' service. Thus, under the best conditions a steel

firebox would last nearly the entire life expectancy of the boiler.49

35 Holley, American and European Railway Practice, p. 91.

36 Master Mechanics Report, 1885, p. 48.

37 Modern Locomotives, p. 7.

38 Holley, American and European Railway Practice, p. 20.

39 Whistler, Anthracite Coal, p. 18.

40 Ibid.

41 Holley, American and European Railway Practice, p. 15.

42 Clark and Colburn, Recent Practice, pp. 55, 58.

43 Engineer, February 8, 1861, p. 6.

44 American Railway Review, August 9, 1860.

45 Master Mechanics Report, 1875, p. 23.

46 Institution of Civil Engineers, Proceedings, Vol. 28 (1869), p. 45'

47 Master Mechanics Report, 1872, p. 28.

48 Master Mechanics Report, 1876, p. 76.

49 Ibid. A boiler was well past its prime after twelve years of use. After twenty years wrought iron boilers became brittle "like very poor cast iron." This is very likely true, but many wrought-iron boilers are known to have given up to thirty years' service.

COAL-BURNING

FIREBOXES

pp. 105 - 108

Although a few roads operated coal-burning

locomotives as early as the 1830's, this fuel was not widely used until many

years later. Coal was scarce and expensive, while wood was plentiful and cheap

until this time. Moreover, when serious experiments with coal-burning began in

the late 1840's, the idea was soon established by ill-advised inventors that

only specialized fireboxes could burn coal successfully. The designs offered

were highly contrived affairs where novelty and complexity rather than

performance appeared to be the goal. Any design, as long as it did not resemble

the ordinary firebox, was offered as a solution to the "coal-burning

problem." Dimpfel, Boardman, and Phleger patented their plans and saw

several locomotives built, but with no practical results. Rogers, Baldwin, and

Norris produced their own, somewhat less complex designs but, again, offered

little of value. By the late 1850's most responsible builders agreed that the

standard firebox with minor modifications was well suited for coalburning. It

was further agreed that the problem was not so much firebox design as good coal

and skillful firing. This is not to say that some notable changes were not

made, but rather that firebox design was modified rather than revolutionized

for coal burning.

This view was well stated in the American

Railway Review of July 12, 1860: "We are at last adopting the belief that

the proper combustion of coal can be effected without any structural

modifications of the ordinary boiler, and, beyond a few air holes, a hodfull of

fire-bricks, or a different form of grate, we are insisting upon the retention

of the locomotive boiler as it is, and upon its proper behavior under the

discipline of coal-burning."

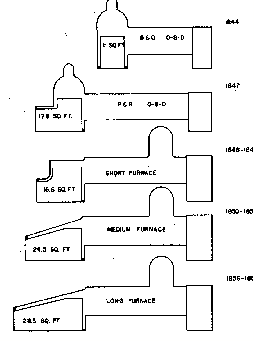

The most fundamental modification for

coal-burning engines was the increase in firebox size. Ross Winans was

unquestionably a pioneer in this field and was the first to build locomotives

with large grate areas for coal-burning. In 1847 he built several eight-wheel

coal-burners for the Reading, each with a grate area of 17.6 square feet. A

common wood-burner in this period had a grate area of only about 10 or 12

square feet. During the next few years Winans devised a firebox of increased

size so that by 1850 or 1852 his engines offered grate areas of 24.5 square

feet. Winans' firebox and boiler designs are traced in the drawings shown in

Fig. 37. In 1844 he abandoned the vertical boiler and adopted the Bury boiler.

This boiler did not provide adequate space for the firebox and was modified in

1847 to include a boxlike structure at the back of the boiler, which increased

the grate area. In 1848-49 the arrangement was improved by moving the large,

Bury style dome forward and making a "step" over the firebox. This

helped to balance the boiler by reducing weight at the firebox end but it did

not provide a much-enlarged grate. In 1850 or 1852 the familiar slope-backed

firebox was adopted. This firebox was not a Winans design as is commonly

believed. It can be traced back to Isaac Dripps's 1848 plan for several

Crampton type engines built for the Camden and Amboy Railroad (1849-53).50 Dripps may have borrowed

the idea from an earlier design.

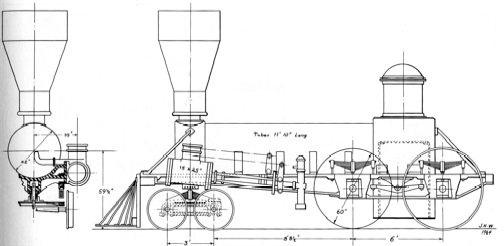

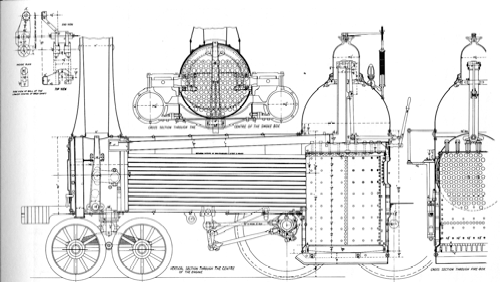

Fig. 37 Horizontal

coal-burning boilers developed by Ross Winans from 1844 to 1857.

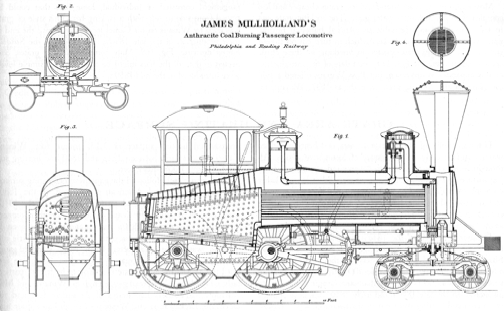

James Millholland was another designer who

recognized the importance of large fireboxes for coal-burning.51 Benefiting from Winans' experience,

Millholland began to perfect a coal-burning firebox for the Philadelphia and

Reading Railroad. His early work involved the rebuilding of several engines

with . enlarged fireboxes (1849-51). Unfortunately, Millholland was sidetracked

from any fruitful results for the next four years by adhering to an impractical

scheme for central combustion chambers which he patented in 1852. The central

combustion chamber was abandoned in about 1855 and a slope-backed design was

adopted. Millholland used the slope-backed firebox at early as 1852 but

unfortunately combined it with the central combustion chamber. He used two

small steam domes, thus making a stronger boiler than Winans' large, Bury style

dome. In about 1858 Millholland introduced the water grate as a means of

increasing grate life. This form of construction required a water space at the

rear of the firebox. Previously,. Millholland had copied Winans' questionable

practice of using no rear water space.

Both the Winans and the Millholland firebox had

fallen from favor by 1870 (for reasons unknown to the author) and neither had a

lasting effect on boiler design. They did demonstrate, however, that a simple,

straightforward firebox of sufficient size was practical for coal-burning.

Winans and Millholland increased the firebox

size by lengthening it. Both inventors achieved modest grate enlargements by

making the firebox as wide as the boiler frame (42 inches) but this represented

a rather small increase in size. Dripps built an engine, the Monster, in

1836-38 with a firebox 43 inches wide. Wilson Eddy increased the width of the

firebox slightly by introducing slab rail frames in 1851. Colburn's giant

Lehigh, built in 1856 for the Delaware, Lackawanna and Western, had a firebox

90 inches in width, but this design lay dormant until 1877 when it was revived

by J. E. Wootten. Essentially, firebox enlargement was confined to longer

rather than wider units until the 1890's when the above frame designs became

more common.52

Other than increased size, the firebrick arch

and the combustion chamber were the most important and long-lived alterations

in firebox design made before 1860. Both devices were intended to improve

combustion and the efficiency of coal-burning boilers. The combustion chamber

was an extension of the firebox into the boiler's waist. The purpose was to

provide more room for combustible gases and air to mix for burning. It was

thought that this could be accomplished more readily in an open chamber than

within the boiler tubes. This was a good arrangement for large, modern boilers

but on the whole it was self-defeating in the small boilers used before 1890. A

combustion chamber of any great length shortened the tubes and thus materially

reduced the heating surface. Aside from this consideration the chamber was a

common source of leaks, a defect not easily corrected until the advent of

modern welding in the twentieth century.

The combustion chamber was in evidence as early

as 1832 on the Camden and Amboy Railroad.53 Dripps also used a combustion chamber on the

Monster (1838) and on several Crampton locomotives (1849), all on the Camden

and Amboy line. Despite this long-established use, the idea was patented in

England by Stubbs and Gryll in 1846. As coal-burning engines became more

common, interest in combustion chambers became widespread. Millholland, Winans,

and other advocates of coal-burning adopted this scheme at an early date. A. F.

Smith, while master mechanic of the Hudson River Railroad, carried the idea to

its extreme by equipping eleven passenger locomotives with combustion chambers

5-feet long. It was claimed that this alteration saved some $60,000 per year in

fuel.54 Few combustion chambers

in this period were more than 18 inches long and many were only 6 inches deep.

The fire arch, like the combustion chamber, was

designed to enhance combustion by improving the mixture of unburned fuel gases

and air in the firebox. This was accomplished by increasing "flame

length," but the fire arch did not take space away from any other element of

the boiler as did the combustion chamber. Water legs and cast-iron fire arches

were used experimentally before 1850, but all such contrivances had a common

failing in that they burned out under the direct action of the fire.

This problem was solved by the firebrick arch,

which was not readily consumed by fire. George S. Griggs is commonly credited

with this invention but Matthew Baird is said to have used the device as early

as 1854 on a number of engines built by the Baldwin Works.55 Baird did not patent

the firebrick arch and thus, if the Baldwin history is correct on this point,

lost credit for one of the most notable single contributions to locomotive

design. Griggs first used the brick arch in 1856 and secured a patent on December

15, 1857 (No. 18883). The patent specification reveals that Griggs apparently

was not aware of the chief merit of the fire arch, the fact that the flame is

lengthened by its passage around the arch; at least there is no mention of this

in the patent. The inventor claims instead that the arch is heated by the fire

to the point of igniting the air and gases as they pass over it. This matter

aside, the firebrick arch was rapidly accepted as part of standard boiler

construction. It could be added to existing boilers; in fact, Griggs developed

it to convert wood engines to coal. Not all authorities agreed that it effected

any measurable fuel economies, but it was recognized by all as an effective

smoke preventer. 56

50 A drawing of Dripps's 1847 slope-backed boiler is included in the 1884 Master Mechanics Report.

51 James Mill Holland and Early Railroad Engineering," U.S. National Museum Bulletin, No. 252 (1967), Paper 69. :

52 Millholland is credited with building the above-the-frame firebox engine, the Vera Cruz, in 1857.

53 Sinclair, Development of the Locomotive Engine, p. 384.

54 Colburn and Holley, The Permanent Way, p. 160.

55 History of the Baldwin Locomotive Works, p. s7.

56 Master Mechanics Report, 1877, p. 104.

GRATES

Grates were a simple, trouble-free mechanism in

the days of wood-burning. Cast-iron bars, often T- or V-shaped, answered

construction needs very well. Each bar was about five-eighths of an inch thick,

four inches deep, and as long as the firebox required. The bars were set about

one inch apart. Because the wood was all but entirely consumed in burning,

rocking grates were not required. The small amount of ash that was not thrown

out through the stack filtered through the grate bars to the ash pan.

Coal presented many more problems and required a

more elaborate grate. It produced a hotter fire, and cast-iron bars burned out

quickly. In 1849 it was reported that ordinary iron grates burned out in one

month.57 Some years earlier

Eastwick and Harrison had designed a wrought-iron grate specifically for

coal-burning. In this plan a U-shaped slot in the top of each bar was filled

with clay.58

The effectiveness of this arrangement is not known, but apparently it was not

successful, because no other reports exist on its subsequent use. A more

successful and longlived arrangement was Millholland's water grate. The grate

was formed of iron tubes that connected the front and rear water spaces of the

firebox. The water grate is illustrated in Fig. 39. Millholland first used the

water grate in about 1858 and saw it used by many other roads burning

anthracite.

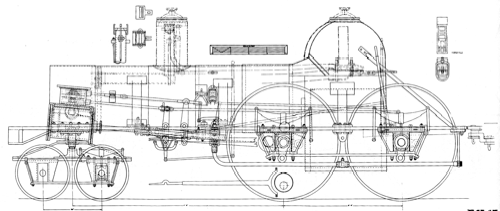

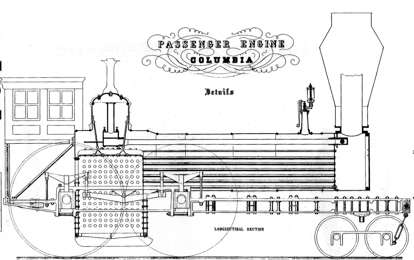

Fig. 39. Millholland's

coal-burning passenger locomotive the Hiawatha, built in 1859 at the Reading

shops. Note the large firebox, water-grate bars, metal cab, and smokebox

superheater.

Most coal-burning roads found rocking grates cheaper and less

complex than Millholland's water grate. The rocking grate was in fact

considered indispensable to soft-coal burning. Bituminous coal formed massive

clinkers which in turn cut off the air supply. The rocking grate assisted in

breaking up these clinkers and reactivating the fire. The exact date of the

introduction of this apparatus is unknown, but Ross Winans offered a simple

plan for the rocking grate as early as 1847. Winans' arrangement consisted of

individual, loose bars that could be tipped from side to side with a jacking

bar. This style of grate was used by Winans on his Camel locomotives until the

end of their production in the late 1850's; it is shown in the Susquehanna

drawing, Fig. 169. More complex rocking grates, connected so that all the bars

might be actuated by a simple lever were introduced in the mid-1850's.

57 Whistler, Anthracite Coal, p. 18.

58 Harrison, The Locomotive, p. 69.

GRATE AREA AND HEATING

SURFACE

p. 110

The importance of adequate grate area and

heating surface was recognized early in the history of locomotive design.

Although there was a tendency to "over-cylinder" engines, heating

surface and cylinder cubic area were held at a remarkably constant ratio (about

200 to 1) between 1835 and approximately 1880. There was, however, an

intelligent movement to enlarge the heating surface proportionately more than

cylinders as the locomotive grew in size.

The typical 4-2-0 of the 1830's rarely had a

heating surface of more than 400 square feet, which was quite adequate for slow

speeds and small cylinders. In the next decade the advent of the heavier 4-4-0

made 500 square feet of heating surface common, with cylinder diameters ranging

from 13 to 15 inches. In the late 1840's and early 1850's the development of an

enlarged heating surface moved forward rapidly. Clobber observed in 1851:

"The heating surface of locomotive boilers has of late years been

considerably increased, not only having been extended with the enlargement of

the cylinders but in a much higher ratio."59 Thus, we find engines

of the early 1850's with 15-inch cylinders but a heating surface of more than

700 square feet. The enlargement of heating surface showed much slower progress

during the next few decades. Yet several designers produced machines with

exceptional heating surfaces. In 1851 Wilson Eddy built the Addison Gilmore with the un-precedented

heating surface of 1,175 square feet. Winan Camel engines built between 1848 and

1860 had heating surfaces of about 1,000 square feet.

Grate area closely followed the expansion of

heating surface The early British and American locomotives of the 1830's

generally had grate areas of about 6 square feet. By the 1840's grate areas of

10 square feet were common. The abandonment of the Bury boiler in the 1850's

made grates of 12 and even 14 square feet possible. Again, as with heating

surface, little real progress was made until after 1875. Most standard-gauge

4-4-0's rarely had grate areas of more than 16 square feet until the 1880's.

Exceptions are of course to be found, particularly with hard-coal or

broad-gauge engines. Winans' and Millholland's coal-burners had grates of 24

square feet and the Delaware, Lackawanna and Western's Lehigh had a grate a of 45

square feet. But such engines were decidedly peculiar American practice of that

time.

During the 1880's the locomotive experienced a

new growth in size which by the end of the decade had become a revolution. By