JOURNAL

OF

THE

FRANKLIN INSTITUTE

OF THE

State

of Pennsylvania

FOR THE

PROMOTION OF THE

MECHANIC ARTS.

DEVOTED TO

MECHANICAL AND PHYSICAL SCIENCE, CIVIL

ENGINEERING, THE ARTS AND MANUFACTURERS, AND THE RECORDING OF AMERICAN AND

OTHER PATENTED INVENTIONS

_____________________________________

EDITED

BY THE COMMITTEE ON

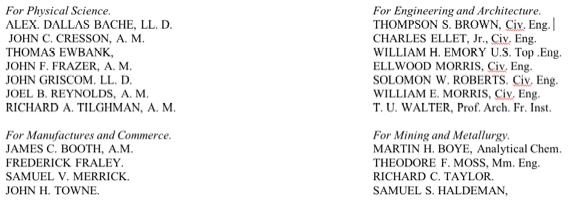

PUBLICATIONS

OF THE FRANKLIN

INSTITUTE.

C. M. KELLER, late Examiner, Patent Office, Washington.

THIRD SERIES.

VOL. XVIII.

WHOLE NO. VOL. XLVIII.

PHILADELPHIA:

PUBLISHED BY THE FRANKLIN INSTITUTES AT

THEIR HALL.

1849

Excerpts from PP. 6 – 12; PP. 77 – 87; PP.

176 – 181

Citations

regarding the experience of the Beaver Meadow and Hazleton R. R,Õs are:

WhistlerÕs

contact with the BMRR and Hazleton roads.

The

success of the BMRR in utilizing anthracite.

Use

of the horizontal boiler in Garrett & Eastwick

engines.

Operations

and repair costs for BMRR and Hazleton coal-burners.

Report upon the Use of

Anthracite Coal in Locomotive Engines on the Reading Railroad, made to the

President of the Reading Railroad Company,

by GEORGE W. Whistler, Jr., April 20,

1849.

John Tucker, ESQ., President.

Sir:

Agreeably to your request that I should make to you a report of my observations

upon the Reading Railroad, relative to the use of anthracite coal in Locomotive

Engines, comprehending its present comparative results with the Engines burning

wood upon that road, and its ultimate economy, deduced from such data as I am

enabled to get from this and other roads using raw coal as fuel, I beg to

submit the following statements:

The Comparison of Engines in their

Consumption of Fuel.

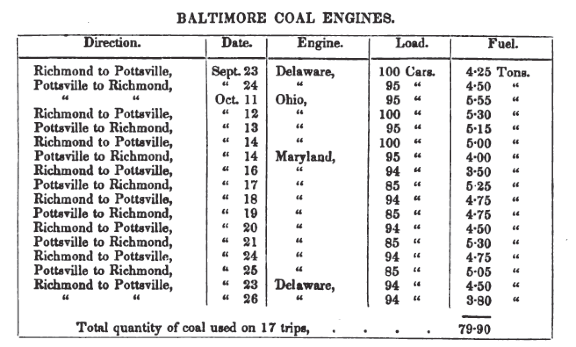

The

observations made by me upon the Reading Railroad,

were between the 23d September and 26th October

of the past year, during which time I was absent

from the road for a period of two weeks, making

examinations of a similar character upon the Hazleton

and Beaver Meadow Railroads. The number of trips

which I record are, 17 of the Baltimore Coal

Engines;

5 of the eight-wheeled Coal Engine Novelty; and 3 of the eight-wheeled wood-burning

Engine Indiana. There were four

other trips made upon the Baltimore Coal Engines,

but not taken into this account; two were broken

by derangement to the Engine, and two were neglected,

being way trips. Two additional trips were made

with the Novelty;

upon one the coal for the use of the Engine was

lost, and upon the other a derangement of the Engine

spoiled the trip. A fourth trip was also made upon

a wood Engine, but with a way tram, and is not included

in this account.

I

give you, further on, a statement of each trip as it was made, and from which I

have calculated the table of comparative results.

For

making these observations, I had every facility extended to me by Mr. G. A.

Nicolls, the Engineer and Superintendent of the road, and all information

relative to repairs of Engines necessary to a satisfactory comparison,

furnished me. I was also permitted to take any Engines in the coal trade for

trial, and run them over the road at such times as would subject them to the

least delays, and give the most daylight for the observations. I availed of

this privilege but twice; being desirous that the trips should be made under

the same circumstances as those recorded each day of the wood Engines, which

were running in their turn by the regulations of the road, and the quantities

of fuel used (consumed or wasted) for each trip was recorded.

As

care is taken to ascertain the quantities of fuel used by the wood Engines, a

statement of which has been made to yourself by the Engineer and

Superintendent, showing what that quantity was for July and August last, I have

not considered it necessary to make observations upon these Engines, further

than to ascertain if the frosty season of the year, during which they were

made, caused any material difference in these results, but as I found none, the

trips were soon discontinued. With the coal Engines, however, the amounts of

fuel consumed per trip have not been ascertained, and my observations have been

directed more particularly to them. The fuel used for the coal Engines was, in

all cases, noted as the difference in weight between that taken at one end of

the road and that remaining at the other. Of the trips here recorded I made

seven myself, two upon a Baltimore Engine and five upon the Novelty, and was assisted in the remainder by

young men whom I put upon the Engines.

9 trips up, coal used = 40.35 = 4.45 per trip.

8 trips down, coal used = 39.55 = 4.95 per trip = 9.40 per round trip.

Average load down, 90 cars, with 450 tons

of coal.

As

the results here given are inclusive of all waste, a deduction should be made,

and a quantity of coal somewhat nearer that actually consumed taken for a comparison

with wood. The coal supplied for Locomotive Engines to the Reading Road is of

good quality, (Forest Improvement,) the only drawback being the large

percentage of fine coal and dirt intermixed with it. Cars containing 55 tons in

weight, have in them from a half to one and a half tons of this dross, a part

of which is thrown from the tender upon the road and estimated as fuel

consumed.

This

waste amounts to about half a ton per trip; I propose, however, to deduct but

five per cent. from the gross weight, as that allowance is made by the parties

furnishing coal, and has no corresponding equivalent in wood.

Five per cent. deducted from 79.9 leaves

76 tons of coal for 17 trips.

Trip up = 4.25 tons. Trip down 4.75tons.

Round trip = 9 tons.

ENGINE NOVELTY.

|

Direction |

Date |

Load |

Fuel |

|

Richmond to Pottsville |

Oct. 10 |

85 Cars |

5.75 Tons of Coal |

|

Pottsville to Richmond |

Oct. 11 |

80 |

6.00 |

|

Pottsville to Richmond |

Oct. 13 |

71 |

5.45 |

|

Richmond to Pottsville |

Oct. 14 |

85 |

5.50 |

|

Pottsville to Richmond |

Oct. 16 |

72 |

5.40 |

|

Total quantity of coal used in 5 trips |

|

28.10 |

|

2 trips up, coal used

11.25 = 5.62 tons per trip.

3 trips down, coal used

16.85 = 5.63 tons per trip.

Coal used per round

trip, 11.25

Deduct 5 per cent for

waste, 10.70 tons per round trip.

Avenge load down, 75

cars, with 375 tons of coal.

The fuel used Oct. 16th,

includes half a cord of wood, which is estimated as one quarter of a ton of

coal.

ENGINE INDIANA.

|

Direction |

Date |

Load |

Fuel |

|

Richmond to Pottsville |

Oct. 9 |

95 Cars |

6.87 Cords of Wood |

|

Pottsville to Richmond |

Oct. 10 |

88 |

7.37 |

|

Richmond to Pottsville |

Oct. 11 |

95 |

7.13 |

|

Total quantity of coal used in 5 trips |

|

21.37 |

|

2 trips up, wood used 14

cords = 7 cords per trip.

1 trips down, wood used

7.37 cords = 7.37 cords per trip.

Wood used per round trip

with 88 cars down, containing 440 tons of coal, 14.37 cords.

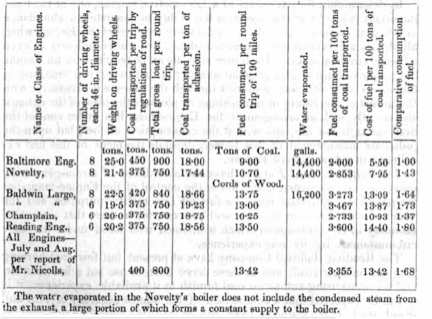

By

the reports for the months of July and August, the fuel used for the Engine Champlain, weighing 20 tons, on six driving

wheels, with cylinders 16 in. in diameter by 18 in. stroke, and working its

steam expansively, is 10.25 cords of wood per round trip of 190 miles.

The

fuel consumed by the Reading-built six-wheeled Engines, shown in the statement

for comparison, is taken from the report for July and August already referred

to, as well as the average quantity of fuel per trip for all wood Engines in

the coal trade during that time. The quantity and cost of fuel per 100 tons of

coal transported, as shown in the summary of the foregoing observations,

includes the return trips with empty cars, the power exerted in either

direction being very nearly the same.

The

Reading Railroad is 95 miles in length, with a total fall of 600 feet greatest

fall at any part of the road, 20 to 25 feet per mile; it has no ascending

grades in the direction of the trade, except within five miles of Philadelphia,

where assistant Engines are stationed. The return load for each Engine is about

one-third the entire gross weight of train brought down,, which is the weight

of cars alone.

Weight of cars, 25 tons, coal in cars, 5

tons.

Total weight of coal and car, 7.5 tons of

2240 lbs.

Cost of wood in the following statement,

$4 per cord, do. of coal, $2.75 per ton of 2240 lbs.

To

facilitate a comparison of the various Engines on the road, a short description

of their principal features is given.

Engine Novelty.

Engine

on eight driving wheels, 46 inches diameter. Boiler on a separate carriage

behind the engine, and connected with it by flexible steam pipes, (a system of

ball and slip joints;) weight of Engine 21.5 tons. Diameters of cylinders 18

inches, and length of stroke 20 inches. Area of fire grate 36 feet, fire

surface 1085 feet. Placed upon the Engine is a cylinder of boiler iron about 42

inches in diameter, and 18 feet long, having a connexion with the water-tank,

immediately behind the boiler. This cylinder of boiler iron answers the double

purpose of giving adhesion to the Engine, and as a condenser for the exhaust

steam from the cylinder, by which the water from the tank is heated before

passing into the boiler; the combustion of coal is promoted by a fan blast.

Baltimore Engines.

Total

weight of Engines with coal, fuel and water, 27 tons; weight on eight driving

wheels 25 tons; do. on two small trailing wheels, 2 tons; diameter of boiler 42

inches; length of tubes 14 feet; diameter of do. 2-5/8 inches; area of grate 18

feet; fire surface 957 feet; diameter of driving wheels 46 inches; diameter of

cylinders 16.5 inches, and length of stroke 20 inches; the draft is regulated

by the variable exhaust in the smoke stack; steam cut-off in the cylinders at

half stroke.

Eight- Wheeled Wood Engines.

Total

weight of Engines 22.5 tons, on eight driving wheels 46 inches in diameter.

Cylinders 15.5 inches in diameter, and 20 inch stroke; fire surface about 875

feet; area of grate about 12 feet.

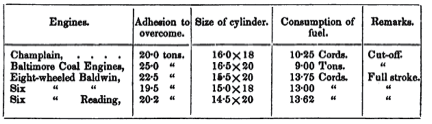

Tabulated Comparison of Engines on the

Reading B. B. Fuel Consumed.

The

foregoing statement shows an accurate comparison of the coal and wood-burning

engines upon the Reading Road in their consumption of fuel; and as the

observations have extended over a considerable time, I have no doubt these

quantities will be found very near the actual consumptions per trip, during the

mild seasons of the year, for then the delays are unimportant, and but few

broken trips occur to swell the averages; still, as it is understood that the

comparative and not the actual quantities of fuel consumed by each class of

Engines is the information sought for, any want of accuracy in estimating the

latter is unimportant.

I

am aware that the results just given of the consumption of fuel differ from

those given by Mr. Nicolls in the report made to yourself last fall. He there

says, that in the spring of 1848 the Baltimore Engines used 9.64 tons of coal

per round trip, but that great care was taken in the selection of fuel, and in

running the Engines; and he further says, that it is his belief that the

everyday consumption of fuel by these Engines is about 12 tons per round trip.

That Mr. Nicolls is mistaken in his belief the facts will show; and he has

allowed himself to be lead into this error by drawing hasty conclusions from

unanalogous facts. Thus, as the experiments made in the spring of the last year

show that 390 tons of coal were transported with an average expenditure of

10.89 cords of wood, and that 425 tons of coal were transported by the Baltimore

Engines with a

consumption of 9.64 tons of coal; that this proportion holds good between the

wood and coal Engines at all times; and therefore, as the actual amount of fuel

used by all the wood Engines, during the months of July and August, was 13.42

cords per round trip, transporting 423 tons of coal, the Baltimore Engines had consequently consumed about 12 tons

of coal in transporting 475 tons of coal.

In

determining the excellence of a Locomotive Engine, one of the most important

points to be considered is the ability to generate an abundance of steam at all

times, not only to do the work required of the Engine when all things, are

favorable to its well-working, but under ordinary or even adverse

circumstances. To insure this, there is required for an Engine the power to

burn a large or small quantity of fuel in a given time, and to this end a large

fire-place and area through the tubes are necessary, with the means of

increasing or diminishing at pleasure the blast of the exhaust steam. By such

an arrangement the Engine-man has under control the draft through the fire, and

with it the consumption of fuel, but upon the judicious management of this

power, depends the merit of this first excellency in a Locomotive Engine.

The

Baltimore Coal Engines

have the abundance of steam-generating power for all emergencies, and under the

control of the Engine-man; but the nature of anthracite coal as a fuel for

Locomotive purposes, and the want of experience in its use, will prevent, for a

time, that degree of economy in its consumption which is attained with wood

under the same circumstances, but by long experience.

The

Reading Railroad Company have at present but few coal-burning Engines on their

road; and as these have been in use but a few months, and no roads using anthracite

coal furnish to it available experience, it is not to be expected that a

comparison of the utmost economy of coal and wood, made in the spring of 1848,

can be made the basis for a rule-of-three method of arriving at the present

everyday consumption of this fuel; facts disprove it; for it will he seen by my

own observations, that the average amount of fuel consumed during the ordinary

working of these Engines for several successive days, over the road, does not

exceed these last spring experiments, while single trips were made with very

much less fuel; it is well known, also, that the Engines have not unfrequently

been run with little more than one-half this consumption of fuel; but the want

of experience in the use of anthracite coal with Locomotive Engines having the

cut-off, and variable exhaust, has been a great drawback to the constant

economical consumption of this fuel.

The

success attending the use of anthracite coal upon

the Beaver Meadow and Hazleton Railroads induced

numerous attempts to be made by the Reading and

other Railroad Companies, to introduce this fuel

by similar means upon their own roads; but the length

of road and heavy business to which the Engines

were subjected soon proved its impracticability;

showing, moreover, that the successful burning of

anthracite coal upon the Beaver Meadow and Hazleton

Roads does not depend so much upon the peculiarities

of their Engines - consisting in an absence of ash-pan

and the exhausting in numerous small jets up the

smoke stack, for the purpose of equalizing the draft

through the fire - as it does upon the short roads

(each 14 miles) and the small amount of work done

by each Engine; and my observations upon these roads

convinced me that their own success falls short

of the requirements of the Reading Road.

Now,

while the quantity of fuel consumed per round trip, under the most favorable

circumstances, in the Baltimore Engines, is stated by Mr. Nicolls to be 9.64

tons of coal, my own observations upon the every-day working of the road show,

in one case, but 7.5 tons per round trip, and I have reason to believe that

round trips have not unfrequently been made with as little as 6 tons of coal.

Again, while Mr. Nicolls estimates that 12 tons of coal per round trip is the

every-day consumption of fuel, the average of my own observations on seventeen

trips is but 9 tons, and the daily observations of the Superintendents of

Engines and Machinery at either end of the road, does not lead them to give a

higher estimate than 9 tons per round trip.

In

explanation of the excess of fuel used in the wood-burning Engines during the

months of July and August, over the experiments made in the spring, Mr. Nicolls

says that the quantities of fuel include that used for way and broken trips,

which always swell the averages. The way trips are a very small proportion of

the trips through (one in ten); and if broken trips have reference to short

trips caused by accidents, these can have increased the quantities of fuel used

per trip but slightly; for during July and August the road was remarkably free

from accidents, I believe entirely so.

By

last year's annual report, Mr. Nicolls estimates that 1,360,000 tons of coal

were transported during twelve months, in average loads and with an avenge consumption

of fuel per Engine as follows:

354

tons transported with 15.83 cords wood in

1847.

423

tons transported with 13.42 cords

wood in July & August, 1848.

69 tons more transported with 2.41 cords wood less.

There

may be great economy in the consumption of fuel this year over that shown in

the report for last year; but I doubt if the quantities for July and August

could be reduced, for the work done, below the statement made above.

With

respect to the Novelty,

and her performance as a coal-burning Engine, I have little to say; I was so

fortunate as to see the Engine for several successive days, under admitted

favorable circumstances, and though it made good time over the road, I could

but agree in the opinion generally entertained and expressed of its entire

impracticability.

It

may be a matter of surprise that this Engine, provided with a condenser, and

having twice the area of grate that the Baltimore Engines have, should consume nearly half as much

more fuel in doing the same work; but a large percentage of the steam generated

is required to drive a fan; and again, there is a loss by condensation and

leakage in the steam pipe leading from the boiler to the cylinders, which is

about thirty feet long, and greatly exposed; there is also a waste of fuel in

the fire-place, caused by its very great size, the heat being so intense from

the mass of fire exposed, as to prevent the men from clearing the grate of

cinder, except just at the door, and consequently the cinder and coal

accumulate upon the grate, and the blast has gradually to be increased as the

Engine progresses on its way. The loss of fuel from this cause is apparent on

the last twenty miles of each trip, the gases formed by the partial combustion

of coal being burned at the chimney top.

The Comparison of Engines in their

Cost for Repairs.

The

most satisfactory comparison of the cost of maintaining Locomotive Engines, is

that shown by a statement of the miles run during a certain period of time; but

when Engines under comparison differ in their construction, for the purpose of

developing some new mode of action, or, as in the case on the Reading Railroad,

for the use of a new fuel, then a fair difference in their cost for repairs

would be that excess caused by the use of one fuel as compared with the other,

and also any excess in repairs caused by a mode of construction differing from

that which is common, but necessary to the use of the new fuel.

The

Reading Railroad has two distinct classes of Engines in the coal trade; the

first and most numerous are the Engines burning wood, and of these there are

several varieties, some on eight and others on six wheels, but all essentially

alike, and the principal part of them were built at Philadelphia by Mr. M. W. Baldwin.

The second class, burning anthracite coal, are few in number, and, with the

exception of the Engine Novelty,

were built at Baltimore by Mr. Ross Winans.

A

description of these two classes of Engines has been given in the first part of

this report, and it is only necessary to explain in what manner the Baltimore

Coal Engines differ from

the eight wheeled wood Engines built at the same time and under the same

specification, with a clause in the contract for the former, having reference

to the burning coal. The essential point in which the Baltimore Engine differ

from the wood Engines, is their having a much larger fire-place and area of

grate for the combustion of coal; this increase of fire-grate was gotten by an

addition made to the ordinary fire-box, and projecting back from that part of

the fire-box immediately under the foot-board; this mode of construction threw

the engine out of balance, for it was found that, of the twenty-seven tons

weight (with coal and water) on eight driving wheels, 16.5 tons were on the

four back drivers, and 10.5 tons on the four front drivers; to correct this

disproportion of weight on the driving wheels, as well as to relieve the Engine

of a portion of its adhesion, a small pair of trailing wheels were placed

behind the fire-box, which bore two tons weight of the Engine, and also

transferred two tons to the four forward drivers, thus balancing the Engine on

its eight driving wheels, with twenty-five tons of adhesion. Of the Engines

proper, cylinders, pistons, cross- heads, connecting rods, crankpins, frame,

boxes, springs, wheels, valves, &c., there is no part of their construction

which has any connexion with the burning of coal, and these parts differ from

similar, parts of wood Engines, as one builder differs from another, for

reasons wholly independent of the boiler and its purposes; therefore the

increased expenditure for repairs on account of the peculiar construction which

is necessary to the use of coal, is confined in these Engines to the increased

size of the fire place, and the small pair of trailing wheels for the support

of its overhanging weight.

The

principal item of excess in the cost for repairs of Engines burning coal over

those burning wood, is caused by the destructive effects of a coal fire upon

the inside sheets of the fire box; and when iron (the soundness of which is

always uncertain from the manner in which it is at present made) has been used

entirely for fire-boxes, this intense local heat has very soon blistered and

burned away the sheets in the immediate vicinity of the coal fire. Another

destructive effect from the use of coal is its severity on the laps or joinings

of sheets in the fire place. To obviate this difficulty much larger sheets were

used, but this again was found to increase the first evil, and finally, the

uncertainty of procuring perfectly sound sheets of boiler iron of large size,

(the difficulty of making them sound increasing with their size,) led to the

abandonment of iron sheets for a distance of two feet above the grate, and the substitution

of copper as a more certainly sound material.

The

experience on the Reading Railroad with anthracite coal has developed a rapid

and unexpected destruction to the copper fire sheets, from the mechanical

action of the sharp particles of coal which flake off' from the fresh coal when

suddenly heated, and impinge upon and cut away the copper sheets forming the

sides to the fire place. The occasional melting of grate bars, the increased

liability to leakage, the wear and destruction to the ends of tubes by

caulking, &c., and the accumulation and igniting of fine coal in the smoke

box, all produce their share of extra expense for repair over wood-burning

Engines.

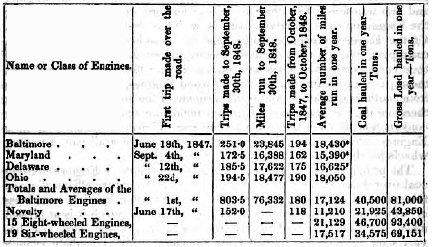

In

order to judge with some degree of accuracy of the use of anthracite coal in

Locomotive Engines, when compared with the use of wood, as well as in its

effects upon the Engines, as the business of the road, I have given the date at

which each coal Engine made its first trip upon the Reading Road, the number of

trips made to the first of October last, and the miles run by each Engine

during one year, estimated from the recorded trips; also the average number of

miles run by the eight and six-wheeled wood Engines as shown by the report for

1841. Of the Baltimore Engines, the Delaware and Maryland had iron fireboxes throughout, while the

Baltimore and Ohio had copper sheets in their fire places,

extending two feet above and one below the surface of the grate. The Novelty, during the time she has been upon the

road, has had two boilers; the first boiler had an iron firebox of very large

dimensions, the second, made in the spring of 1848, also has an iron fire-box,

but of smaller dimensions.

Tabulated Comparison of Engines on the

Reading Railroad - Miles Run.

*Time lost by renewing fire

-sheets, included in the year.

The

Baltimore, which came

upon the road June 18th, 1847, completed her 251 trips in August, 1848, at

which time she was brought into the shop to have the copper sheets in the fire

place renewed, and did not commence her trips again upon the road till October

23d. The Maryland and

Delaware each had

their iron fire sheets renewed with copper, after seven months use. The Ohio

has still, April, 1849, the original copper sheets in her fire-box.

By

the foregoing statement, it will be seen that the Baltimore's copper fire place has lasted fourteen

months; this is about one-third of the time experience had proved similar fire

places to last in Engines burning bituminous coal upon the Baltimore and Ohio

Railroad, and from which experience it was confidently expected that the copper

fire places in Engines burning anthracite coal would last two years. The

immediate cause of this speedy destruction on the Reading Railroad is the large

quantity of fuel which is required to be burned in a given time, thus hastening

the destructive effects of coal, as already explained, in proportion to the

quantity consumed.

The

extent of the destruction to fire sheets caused by the mechanical action of the

particles of coal is very limited, about fourteen inches in width through the

entire length of the fire place, seven inches above and the same below the

surface of the coal fire. In the line of the staybolts, both vertically and

horizontally, the copper retains its original thickness, and upon the copper

sheet immediately below the tube or flue sheet, there is no indication of wear,

and none could take place from the causes just mentioned; for the particles of

coal which are carried towards the tubes, bank against and protect this sheet.

The melting of grate bars consequent upon the use of coal is quite uncertain, I

have known whole sets to be destroyed as often as once a month, and again, with

care, a single set to last several months. The principal causes which govern

this waste are, the care bestowed by the firemen in keeping clear the

fire-grate and ash-pan, and the nature of the coal used. If cinder is allowed

to adhere and accumulate upon the grate, it will soon be destroyed; for the

current of air is prevented that free access through all parts of the grate so

necessary to its preservation. The neglect, however, to keep the ash-pan free

from cinder and ashes, and when free, flooded with water to the depth of

several inches, is the great cause of destruction to the grate bars. With bad

coal, grate bars have melted by the accumulation of cinder which has taken

place in a single trip; this, however, rarely occurs. The extra caulking of

tubes, which is required by the use of coal, makes it necessary in time to

remove the tubes, and to weld on new ends; some slight wear is also caused

within a few inches of their ends by the mechanical action of the particles of

coal, but producing no material injury.

I

have thus stated the causes which produce the principal excess of repairs in

Engines burning coal, over wood-burning Engines, and submit below an estimate

of the entire extra cost of the Baltimore coal Engines, (so far as this cost for repairs

relates to the burning of coal,) over the Engines burning wood upon the Reading

Railroad of like power.

Cost per Engine for

Renewing Fire Box.

|

800

lbs. Copper Fire-sheets, at 26cents, . . . . . . . |

$20,800

|

|

110

lbs. Copper Stay-bolts, " . . . . . . . . . |

28.6 |

|

66

lbs. Iron Stay-bolts at 6cents, . . . . . . . . |

3.9 |

|

2-1/2

days' work cutting stay-bolts, at $3, . . . . . . . . |

7.5 |

|

7

weeks' work of two men removing old and renewing fire-sheets, at $10 per

week, |

140 |

|

7

weeks' work of two men, at $7 per week, at ditto, . . . . . |

98 |

|

|

486 |

|

Deduct

for 600 lbs. old copper, at l8cents, . . . . . . . |

108 |

|

Cost

for renewing fire-place, . . . . . . . . . . |

$378.00

|

|

The

Baltimore's copper fire-place

was renewed after fourteen months' service, and if this be supposed the limit

of durability on the Reading Road, it will involve an annual expense of . . .

. . . . . . . . . . . |

$324.00

|

|

Deduct

for depreciation of fire-box of wood-burning Engines in this time |

75 |

|

Remaining.

. . . . . . . . . . |

$249.00

|

Extra

Cost per year or Wood Engines, for each Baltimore Coal Engine on the Reading

Railroad, from the use of Anthracite Coal

|

Cost

for renewing fire place, . . . . . . . . . . |

$249.00

|

|

3sets

of grate-bars, - 3225 1bs.cast iron, at 23cents, . . . . . . |

80.64 |

|

Door

plates, 500 lb. cast iron, at 2-1/2 cents, . . . . . . |

12.5 |

|

4

daysÕ work of two men removing 50 tubes, at $1.75 and $1, . . . |

11 |

|

7

days' work of two men welding new ends to tubes, at $1.75 and $1, |

20.63 |

|

831b.wrought

iron for repairing tubes, at 6cents,

|

4.98 |

|

3

days' work of three men caulking tubes, one man at $l.75, and two at $1 per

day, |

11.25 |

|

Extra

work, caulking, &c., . . . . . . |

20 |

|

Work

in smoke box, . . . . . |

35 |

|

1

set of trailing wheels, 300 lbs cast iron, at 2cents, . . . . |

7.5 |

|

1

day's work of two men fitting up ditto, at $2 and $1.50, . . |

3.5 |

|

|

$456.00

|

Experience

proves that much unnecessary expense may be avoided in renewing the copper fire

sheets of these Engines; for all that part of the copper which extends below

the surface of the grate (thirteen inches) is entirely uninjured, and therefore

does not require to be removed, and in estimating the necessary cost for

repairs of these Engines, the item of copper may be reduced one-third, and in

constructing Engines of equal power, a saving may be made in the original

outlay, as sheets of copper twenty-five inches wide will be found quite

sufficient for all purposes of protection from intense heat, for the water way

in the fire-place need not extend below the grate further than is common, say

one or two inches.

I

have made no comparative estimate of the cost for repairs for the Baltimore

Coal Engines and the

coal Engine Novelty;

the miles run during one year by these Engines is the most satisfactory that

could be made. The fire-place of the Novelty's boiler has proved quite as destructible

as the fire-place of the Baltimore Engines; already several sheets have been renewed in the new

boiler, after a few months' work; and I think it will be found, that although

made uncommonly large, for the purpose of diffusing the local heat, its cost to

keep in repair (when compared with the fireplace of the Baltimore Engines) will be found to increase in proportion

to its size. In the destruction of grate bars, wear and tear of extra parts and

machinery necessary to her coal-burning peculiarities, there can be no doubt of

greatly increased costs over the Baltimore Engines.

Experience of the Baltimore and Ohio

and other Railroads, in the use of Coal in Locomotive Engines.

It

will be difficult to form any correct estimate of the value of anthracite coal

as a fuel in comparison with wood, from any direct experiments that were made

on the Baltimore and Ohio Railroad, from its earliest introduction in 1831, to

its final abandonment for bituminous coal in 1840. The early reports of this

company give a great many facts, and show most conclusively that this coal was

used with entire success in all the Engines on the road, which, in 1840,

numbered fifteen on the "Main Stem." The Engines were built with

upright boilers expressly for the use of anthracite coal, and no experiments

were made to test its relative value with wood. The company did not determine

to use coal on the score of economy, for at the opening of the road, and for

some time after, coal was $8 per ton, while wood did not exceed $2.50 per cord,

the danger from fire, however, by the use of wood, but, more than all, the

precedent of the English Railways then just coming into successful operation,

which pointed to a mineral fuel as seemingly the only fuel fit for Locomotive

Engines, were the considerations which induced its use. In the spring and

summer of 1840, however, an investigation was made of the relative values of

anthracite and bituminous coal, by Mr. James Murray, then Engineer of Machinery

on the Baltimore and Ohio Railroad; these experiment will enable a fair

comparison to be instituted between anthracite coal and wood; for the oft

repeated trials of bituminous coal with wood have established their equivalent

quantities beyond a doubt.

To

a more ready understanding of the facts which I shall present of the experience

with fuel on the Baltimore and Ohio Railroad, and the application of these

facts to the Reading Road, a short description of this road to its present

terminus is given. The road is 178 miles long, but divided for working into two

portions; first, from Baltimore to Harper's Ferry, 80 miles; second, from

Harper's Ferry to Cumberland, 98 miles.

Baltimore to HarperÕs Ferry.

|

8 miles rise 30 to 40 feet per mile, |

|

7 miles fall from 30 to 40 feet per mile, |

|

2 miles rise at 82feet per mile, |

|

2 miles fall at 82feet per mile, |

|

46 miles rise and fall from 0 to 30 feet per mile. |

|

15 miles level. |

|

80 miles total length, with a total rise of

852feet, and fall of 647feet. |

|

15 miles are curved with a less radius than 1000 feet. |

|

Total curvature, 31 circles of 3600. |

|

80 miles of edge rail, 51 lb.. per yard. |

|

30 miles of plate rail, 15 lb.. per yard, (portion of double track.) |

|

Gross load for Engine, weighing 23.5 tons - 200 tons |

This

load is regulated by the necessity for carrying it a portion of the distance on

the plate rail. At the 82 feet grades assistant Engines are provided.

Harper's Ferry to Cumberland

|

14 miles, rise from 30 to 40 feet per mile. |

|

10 miles fall from 30 to 40 feet per mile. |

|

33 miles rise and fall from 0 to 30feet per mile. |

|

41 miles level. |

|

98 miles total length,

and with a total rise of 998 feet, and fall of 634 feet. |

|

1.6 miles are curved with a lees radius than 1000 feet. |

|

Total curvature, 29 circles of 360¡. |

|

98 miles of edge rail, 51 lbs. per yard. |

|

Gross load for Engines weighing 23.5 tons - 275 tons. |

|

|

The

first successful effort to burn anthracite coal in Locomotive Engines was made upon

the Baltimore and Ohio Railroad in 1831, by Phineas Davis, of York,

Pennsylvania, in a small Engine built by him, having an upright boiler; the

weight of this Engine was 3.5 tons, and was capable of transporting 15 tons at

fifteen miles per hour. The same plan of Engines was adopted and adhered to for

this road until 1838, with modifications and improvements from time to time;

chiefly consisting in an increase of their weight, 12.5 tons being the maximum.

These Engines are now in successful operation, transporting merchandize and

passengers, and show themselves quite equal to compete with those of larger and

later constructtion. In 1833 the Engine Atlantic, weighing 65 tons, with 4 tons on the

driving wheels, ran 13,280 miles, at 80 miles per day, with the consumption of

190 tons of anthracite coal. Gross load 23 tons. In 1834 the Engine Arabian, weighing 7.5 tons, on four driving

wheels, consumed 1.25 tons of anthracite coal per trip of 80 miles. Gross load

45 tons. In 1840, when anthracite coal was abandoned for bituminous, a trial

for two months was instituted in the same Engine, weighing 10.5 tons. Gross

load 60 tons. This Engine ran to Frederick, distant 60 miles, and consumed 1

ton of bituminous coal to 1.25 of anthracite, and these results, I am told by

Mr. Murray, held remarkably true throughout the trial. In 1840 and 1841, an

accurate account was taken of the fuel consumed in eight wood and eleven

coal-burning Engines. The wood-burning Engines weighed each 10 tons, with 6.5

tons on a single pair of driving wheels. The coal Engines weighed 9.75 tons on

two pair of driving wheels.

8 Wood Engines, running

78,443 miles, consumed 2023 cords pine wood.

11 Coal Engines, running

77382 miles, consumed 1597 tons bituminous coal.

Wood consumed per trip

of 80 miles with 40 tons gross load, 2.05 cords.

Coal consumed per trip

of 80 miles with 60 tons gross load, 1.65 tons.

Proportion of coal to

wood consumed per load taken, 1 ton to 1.87 cords.

No

further additions were made to the stock of coal-burning

Engines on the Baltimore and Ohio Railroad until

1844, the road then being open to Cumberland. In

October of that year, Ross Winans produced the first

successful coal-burning Engine with a horizontal

boiler; for the Baltimore and Ohio Railroad, like

the Reading Road, had made an unsuccessful effort

to burn anthracite coal in an Engine built for them

by Eastwick & Harrison, with a horizontal boiler,

similar to the Engines furnished by the same parties

to the Beaver Meadow and Hazleton Roads. Of the

Engines built by Ross Winans, with horizontal boilers,

six were placed upon the road between October, 1844,

and July, 1845, and six others between July and

December, 1846. One other Engine, substantially

like these, but built by the company, was placed

upon the road in May, 1847. These thirteen Engines

weigh each 23.5 tons, and have eight driving wheels

33 inches in diameter. Speed is attained through

the medium of cog-gearing. The first six Engines

were without copper fire-sheets, but renewed with

copper after one year's service with the iron. The

later built Engines wert all constructed with copper

fire-sheets.

The

coal consumed by these Engines in 1845, was 3.25 tons between Baltimore and

Harper's Ferry, with a gross load of 200 to 250 tons. In September and October,

1848, twenty-four trips were made with the same Engines on the upper or

Cumberland end of the road, and thirty trips on the lower or Baltimore end of

the road, for the purpose of testing the value of different coals. Average

gross loads between Baltimore and Harper's Ferry, 200 tons, coal consumed, 2.25

tons per trip of 80 miles. Average gross loads between Harper's Ferry and

Cumberland, 275 tons, coal consumed, 2.5 tons per trip of 98 miles. For a more

ready comparison of the results which are known of the consumption of fuel on

the Baltimore and Ohio Railroad, I have placed them in the following table:

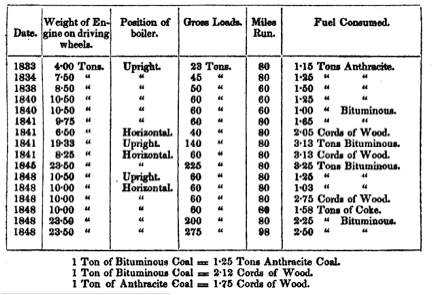

Table Showing the

Amount, of Fuel Consumed on the Baltimore and Ohio Railroad at Different Periods,

from 1833 to 1848.

The

cost for repairs of the large coal Engines on the Baltimore and Ohio Railroad,

I am able to give with much accuracy; the annual reports furnish some of this

information, but to Mr. Perkins, the Master of Machinery, I am indebted for

details.

In

1841, the thirteen large coal Engines ran each 16,000 miles; in 1848, they ran

17,000 miles, anti cost for repairs $1777 each; of this sum, however, a portion

is due to the geared construction, which adapts them to the short curves of

this road, but that which is due to coal-burning is as follows: Cost for

renewing the fire-sheets of 23.5 tons Engines on the Baltimore and Ohio

Railroad, after deducting for old copper, $300. Area of fire-grate, and amount

of copper in fire-place, one-third less than Reading coal Engines. This

difference in the amount of copper is not a necessary one, for the sheets of

copper in the Reading Engines are wider, by ten inches, than the fire-sheets of

the Baltimore and Ohio coal Engines, and do not extend above the grate a

further distance.

In

six of these large Engines, the copper fire-sheets were put in between

November, 1845, and June, 1846, and one only has been renewed since; and, from

their resent appearance, there is no reason to doubt their lasting through this

year. In giving the extra cost for repairs of these Engines, $100 per year is

taken to cover the destruction to the fire-box.

Extra Cost per year, over Wood

Engine., for each 23.5 ton Coal Engine on the Baltimore and Ohio Railroad from the

use of Bituminous Coal

|

Cost

for renewing fireplace, . . . . . |

$100.00

|

|

2

sets of grate bars, 1000 lbs. cast iron, at 2-1/2 cents, . |

25 |

|

Renewing

ends of tubes, caulking, &c., . . . |

100 |

|

Extra

work, caulking, &c., . . . . . . |

25 |

|

|

$26,000

|

In

1842, the Western Railroad Corporation of Massachusetts, purchased seven large

coal-burning Engines of Ross Winans; these Engines were on eight driving wheels

thirty-three inches in diameter, and geared for speed; weight of Engines, 20 to

23 tons; boilers upright; area of grate, 24 feet. In April of the same year,

the Engineer of the Road, by an order of the Board, had trials made for five

successive days with the Engine Maryland, weighing 20 tons, for the purpose of ascertaining the

quantity of fuel consumed. These trials were made on that portion of the road

between Albany and Springfield, distance 100 miles. In running 500 miles with

fair loads due to the adhesion, the consumption of fuel (anthracite coal) was

2.5 tons per trip of 100 miles. The large wood-burning Engines on that road,

weighing 20 tons, with 14 tons on four driving wheels, (when drawing their

load,) consumed four cords of wood per trip of 100 miles. This comparison of

wood and coal shows 1 ton of anthracite coal to be equal to 2.26 cords of wood;

a comparison more favorable to anthracite coal than any I know of. The upright

boiler, however, of these Engines, with their large area of grate, were well

adapted to burn anthracite coal; while the hemlock wood used on this portion of

the Western Railroad was an inferior fuel to the mixture of pine and oak common

in this section of the country.

The

use of anthracite coal was continued in these Engines until the close of the

year 1842, when, from motives of economy, (cost of coal $7 per ton, and wood $3

per cord,) and to ensure greater regularity on a long line of road, with a

single track and a heavy business, (which the want of experience in the use of

this fuel in some degree prevented,) coal was abandoned for wood. As

wood-burners, these Engines were not economical; and as the upright boiler was

a source of considerable expense, owing to the sediment which collected on the

tube-head, they were, in 1846, placed in ordinary and other Engines substituted

on the road.

The

Beaver Meadow Railroad is fourteen miles long from

the foot of its inclined planes, where it is intersected

by the Hazleton Railroad, to its terminus at Much

Chunk. The grades of this road are eighty feet per

mile, till it strikes the Lehigh river, distant

five miles; and from this point to Mauch Chunk (nine

miles) the road falls with the river from twenty

to fifty feet per mile; it has short curves al is

laid with a light plate rail.

There

are six Engines on the road burning anthracite coal, they weigh about fourteen

tons, with ten tons on four driving wheels. The first Engine was placed upon

the road in 1837, and was built by Garrett, Eastwick & Co. Loads for

engines up the grade, forty-five tons gross, exclusive of Engine and tender

(seventeen tons). The work is done upon this portion of the road with three

Engines, each running daily seventy miles during twelve hours, and the fuel

consumed is about 2.75 tons of anthracite coal per Engine. Gross load per round

trip of 28 miles, 230 tons.

The

Hazleton Railroad, from Hazleton to its intersection with the Beaver Meadow

Road, is nine and a half miles long, and from this point to the Lehigh river at

Penn Haven, (five miles,) the Beaver Meadow Railroad is used in common by the

two companies. The grades upon the first four miles of the road from Hazleton

are light; then descending at sixty feet per mile for four miles; and then at

one hundred and forty feet per mile for one and a half miles, to its

intersection with the Beaver Meadow Road; the loads up the one hundred and

forty feet grade are divided. The remaining five miles over which the Hazleton

Company carry their coal, fills at eighty feet per mile to the Lehigh river.

Road laid with plate rail and short curves. Engines similar to those on the

Beaver Meadow Road; first one went to work in 1839. Number of Engines at work

each day, loads taken, miles run, and fuel consumed, same as Beaver Meadow Road.

The

cost for repairs of Engines on these two last-named roads, 1 am not able to

give; but as experience shows that the fire-boxes (which are of iron) last from

five to six years, the extra cost for repairs due to the use of anthracite coal

would appear very immaterial. There are, however, considerations which should

betaken into account in judging the value of the results in the use of coal on

these roads. During the three winter months, these roads are not worked, and

the amount of fuel consumed is about two-thirds of that consumed in the Engines

on the Reading Road in the same working time. The short run (not exceeding

fourteen miles) also enables a thin fire to be kept, which is cleared of cinder

at each end of the road, while the Engine is being turned and attached to its

return load; but, before starting, it becomes necessary to replenish the

fire-place with wood, and thus a new fire is kindled every few hours in the

day. This system is quite practicable on roads where the consequent delays are

not felt, but entirely inapplicable to the Reading Road.

Conclusion.

In

concluding this Report on the use of anthracite coal in locomotive engines,

with reference to the present practice and prospective results upon the Reading

Railroad, I would offer a few remarks touching the facts just recited,

confident that these facts comprehend all that relates to mineral fuel in

locomotive engines which is desired to be known by your company, and will

establish the proportion of coal to wood consumed, and also the extra expense,

in repairs of engines, consequent upon the use of this fuel.

The

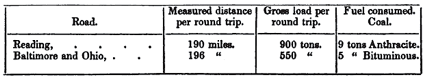

results of the observations upon the Reading Road have been given in detail,

and the proportion of coal to wood consumed for equal amounts of work done, is

shown to be 1 ton of anthracite coal in the Baltimore engines, to 1.8 cords of

wood in the Reading built engines, 1.64 cords in the eight-wheeled Baldwin

engines, and 1.37 cords in the engine Champlain, built also by Mr. Baldwin.

The

apparent discrepancy in these results may be accounted for in the effect

produced by cutting off the supply of steam to the cylinders of some of the

engines after a portion of the stroke is made; which, in well proportioned

engines, results in an economy of fuel. Of the engines under consideration, the

Baltimore coal-burners and the Champlain are cut-off or full-stroke engines at pleasure, while the

eight and six-wheeled wood engines are worked at full stroke only.

In

making comparisons from the consumption of fuels, I shall endeavor to show,

from the relative merits of these several engines, how coal may reasonably be

expected to compare with wood, when all the engines are using fuel

economically, taking the Champlain for the standard, as the best proportioned

engine on the road for the adhesion she has to overcome, and as comparing

favorably with like engines upon other railways in her consumption of fuel.

The water evaporated by these amounts of

fuel I am not able to state, except in the instance of the coal engines at

14,400 gallons, and the eight. wheeled wood engines at 16,200 gallons. This

element for all the engines would, however, facilitate their comparison, though

no strictly scientific investigation is aimed at, and none was contemplated at

the time of making the observations.

It

will be seen, by inspecting the above table, that the cylinder power of the

Baltimore coal engines is less, for the adhesion they have to overcome, than

the Champlain's; and

therefore they require to be worked either on the full stroke, or, if on the

cut-off, under a very high pressure of steam, which results, indirectly, in the

greater consumption of fuel for work done. To understand this clearly, it must

be borne in mind that the use of the cut-off on coal engines has a more

important bearing on, the economy of fuel than the same arrangement upon a

wood-burning engine, and for these reasons: when the coal engines are worked

upon the full stroke, the exhaust is very strong, and the draft through the

fire proportionally increased; this soon produces an exceedingly hot fire, and

every fresh supply of coals thrown upon it at once crumbles and compacts upon

the grate, offering increased resistance to the passage of air through its

mass, while less perfect combustion results, and much of the finer coal upon

the surface is carried through the tubes and wasted. This "cutting-up" of the fire, as it is termed, will

take place when necessity requires that the engine should be worked upon the

full stroke, and for this reason the cut-off becomes indispensable to a good

coal-burning engine.

The

first effect produced by a change from the full stroke to the cutoff is that of

lessening the draft through the fire by the moderated exhaust in the stack,

evaporation then goes on more slowly in the boiler, and would reduce the

pressure of steam necessary to working on the cutoff, were there no means of

again increasing the intensity of the draft. The variable exhaust, however,

furnishes this with facility, and evaporation again becomes rapid, though with

much less disturbance to the fire. All these considerations were well

understood at the time the Baltimore coal engines were being constructed, and

the necessity for cylinders even of a greater diameter than 16.5 inches, in

anticipation of an adhesion of only twenty-three tons, was urged by the

builder, but not allowed by the engineer of your road. This restriction,

together with the increased weight of the engine beyond that anticipated, has

impaired the beneficial effects of the cutoff on the Baltimore coal engines to

such an extent, that economy in the consumption of steam, and more quiet

combustion of coal, is almost counteracted by the rapid evaporation required

for the small cylinders. 1 would not be understood by this to controvert the

received truth, that the same quantities of heat will evaporate equal

quantities of water under all pressures; for so far as this question alone is

considered, mere size of cylinders could have no effect in increasing or

diminishing the quantity of fuel consumed; but for the practical difficulties

just stated, and the fact that, for higher pressures, higher temperatures are

required, and therefore radiation from all parts of the boiler must take place

to a greater extent, a larger expenditure of fuel will result. To this loss

there must also be added that caused by leakage, which is in direct proportion

to the pressures; and when it is required to carry steam very high,

self-preservation teaches men to keep the boiler blowing off all the time, as

the only surety that steam is not made too fast.

When

the Baltimore engines are worked on the full stroke, they make an abundance of

steam with seven inches area of blast-pipe, though the effect upon the fire is

to cut it up, as explained; but when working on the cut-off, the area of the

blast-pipe requires to be so reduced, that much of the ill effects on the full

stroke are felt, and the resistance due to the blast-pipe is also greatly

increased, for its area may be reduced to 2.25 inches. No better proof of' the

inadequacy of the cut-off alone, to ensure economy with the present size of

cylinders, can be offered than the fact that, except where attention has been

paid by the engine-man to the variable exhaust, the economy due to the cut-off

has not resulted from its use.

During

the early working of these engines on the Reading Road, it was with much

difficulty that men could be induced to use the cut-off and the engines were

for some time worked on the full stroke, with a consumption of about 10.5 tons

per round trip; now the cut-off is used entirely on all the engines, and yet,

by referring to the observations made upon the Ohio, her consumption of fuel is

not diminished; while, again, it is seen that the same engines have made trips

over the road under the same circumstances with one-half this quantity of fuel.

Where

so much depends upon men, it is almost impossible to say what may be

accomplished with the engines as at present proportioned. The best results

obtained with these engines show that one ton of coal is equal to two cords of

wood in the Champlain,

and the avenge every- day work upon the road shows that they compare with this

engine as 1 to 1.37; this is allowing nine tons of coal to the round trip, a

quantity, however, which they do not consume, for I should estimate that one

ton of this is thrown or wasted from the tender, the floor of which is grated;

coal, moreover, is so plentiful on the Reading Road that care is not taken to

preserve, for stationary purposes, that which is not considered the best for

locomotives; but, without regard to this waste, I am of opinion that the

engines, as they are constructed, may be made to do their work every day, with

a consumption of fuel which shall not exceed one ton of coal for 1.62 cords of

wood in the best wood-burning engine on the road. With the other wood-burning

engines, the coal-burners would compare more favorably, even should the cut off

be applied to them. It is quite practicable to substitute cylinders 18 inches

in diameter on the Baltimore coal engines, in place of the 16.5 inches, and

then the consumption of coal to wood, in all probability, would bear that

proportion which experience proves attainable, viz: one ton of anthracite coal

to two cords of wood.

In

reviewing all the facts touching the consumption of coal in locomotive engines,

I would draw your attention, in conclusion, to the table of fuels consumed on

the Baltimore and Ohio Railroad, from 1833 to 1848. By an examination of this

table it will be seen what experience alone can do in reducing expenditures,

for it will be easy to detect the same engine through a period of years, and

see her progressive economy in the consumption of fuel. Time and experience

alone have accomplished this, and much may be expected for the Reading Railroad

when, by the more general use of anthracite coal, it shall be regarded less a

matter for experiment than an important element of railway success, to be

perfected with care and attention.

The

subject of extra cost for repairs of coal over wood-burning engines has been

investigated with care, and it will be unnecessary here to enlarge upon what

has already been said; the statements in detail show what the extra cost has

been for the Baltimore engines, and I propose now to offer a few concluding

remarks, suggested by past experience, upon the probable diminution in this

expense.

Experience

thus far proves that the copper fire-sheets are destroyed far more rapidly by

the mechanical action of the particles of anthracite coal than, by the intense

local heat, and it becomes, therefore, a matter to be considered in renewing

these sheets, whether copper may be made more secure against this unexpected

deterioration, or whether it might not be well to resort again to iron; for if

with care and means it can be made sound, it will not only be more economical

in its first cost, but resisting as it does the mechanical action of the coal,

will last a long time, and reduce the present cost for repairs to a very small

amount.

The

estimate which has been submitted of the actual cost of renewing the fire-place

of the engine Baltimore is $378; if deduction be made for one-third less

material in fire-place, (as explained,) this expense will be reduced to $345.

The principal consideration, however, is, how frequently will these copper

sheets require renewing? - the first copper fireplace has been destroyed after

fourteen months' service over 23,845 miles of road, but experience has

suggested improvements in renewing these sheets; additional stay-bolts have

been put in the fire-box to prevent the copper, (which becomes very ductile by

the intense local heat,) from being bulged out, and thus forming projections in

the fire-place, readily acted upon by the particles of coal in motion. By this

additional security to the Baltimore's copper fire-sheets, there is reason to

believe that its fire-box will last two years, and I submit an estimate of the

annual cost for repairs of these engines in accordance with this view.

|

Cost per annum for renewing fire-sheets 26 inches wide, after two years' service, |

$172.50 |

|

Cost per annum for all other expenses, . . . . . . . . |

207 |

|

Total cost per annum over wood-burning engines, . . . . |

$379.50 |

Iron

would undoubtedly be a better material for fire-sheets than copper, but the uncertainty

attending its use has caused it to be discarded in coal engines upon roads of

any length and business; this has been the case on the Baltimore and Ohio

Railroad with the use of bituminous coal, though less destructive in its

effects than anthracite. Iron-masters, however, have not been called upon for a

quality of iron so superior as that required for the fire-places of coal

engines; but when it is understood that such iron will command a ready sale and

price, in proportion to its cost, I doubt not but it will be produced.

Whether

copper or iron shall be the material used, experience shows that great

advantage is gained by constructing the fire-boxes so that repairs and renewals

of sheets, may be made with the least expense in time and materials; attention

to this has resulted in producing coal engines of a later construction than

those on the Reading Road, with their fire-places much simplified for this

important consideration.

There

are other parts of the fire-box liable to depreciation beside that part in the

immediate vicinity of the coal fire, but they have not been referred to by me

in the estimate for repairs just given, as experience had shown that such

parts, (crown, side, and back sheets,) when more than twenty inches above the

grate, had not required renewing, either on the Reading Road with the use of

anthracite coal, or on the Baltimore and Ohio Road with the use of bituminous

coal; it was not, therefore, considered of sufficient importance to estimate in

detail this possible extra expense, but it was believed that the

above-mentioned sum of $379.50 would be found quite sufficient to cover all

contingencies, even with the present early experience with coal engines; for

when, after several years' working of an engine, it shall become necessary to

renew these sheets, the cost per annum to cover this expense will be but small.

I

have made no allowance for renewing the tube or flue sheet in the fire-box end

of the boiler, as such extra expense is not necessarily entailed on

coal-burning engines. Before sufficient experience had been had with coal

engines, these tube sheets were put in too thin, and the distance between the

tubes was so slight that the operation of caulking broke the head through from

one tube to the other. I am aware that such difficulty is experienced with the

Baltimore coal engines on the Reading Road, but the present mode of renewing

such sheets will prevent this expense recurring sooner than with wood-burning

engines.

In

comparing the cost for repairs of fire-place, tubes, &c., in any engine on

the Reading Railroad, with similar repairs of engines on other roads, the

amount of fuel consumed in a given time is that which will determine their

relative periods of duration. Now the Reading Road has great advantages over

all other roads in this country, in the amount of work which can be done over

it in a given time, for its grades are light and descending in the direction of

the trade; and when the work of each engine on this road is compared with the

work on an undulating road, such as the Baltimore and Ohio Road from Harper's

Ferry to Cumberland, it will be found that the consumption of fuel is in

proportion to the work done.

If the Baltimore and Ohio Road, (whose measured

distance is about equal to the Reading Road,) had no grades exceeding the angle

of repose; or, in other words, no grades which allowed a load to be propelled

entirely by its gravitation, then the statement above would show the

proportions of work done to coal consumed in running the same number of miles;

but when the grades exceed this limit, (30 feet per mile, or 12.78 lbs. per ton

for friction being taken as the angle of repose,) then all such distance must

be equated in order to arrive at the whole work done. By referring to the

description of the Baltimore and Ohio Railroad from Harper's Ferry to

Cumberland, it will be seen that fourteen miles ascend, and ten miles descend,

at a rate of thirty to forty feet per mile, thus making in the round trip

twenty-four miles of this grade to be overcome, and the same distance to be

moved through by the gravitation of the load. The ascending grade will be equal

to about fifty-two miles of level road, and as steam is necessarily made and

blown off in descending the twenty-four miles by gravity, it is estimated to be

equal to taking the load over eight miles of level road; this will make sixty

miles of equated distance in place of forty-eight of measured distance. The

curvature of the Reading Railroad, and that portion of the Baltimore and Ohio

Road between Harper's Ferry and Cumberland, is about equal.

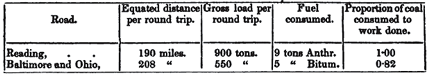

It

has been shown that the miles run during the past year by the coal engines on

the Reading Road, and by engines of the same class on the Baltimore and Ohio,

were about 17,000, but, by the above table, it will be seen that the work done

in the same time is in the proportion of 1 R. to 0.56 B.&O., and the coal

consumed to do this work, in the proportion of 1 R. to 056 B. & 0.,

consequently the duration of fire-places, &c., will be in the proportion of

0.56 R. to 1 B.&O. Anthracite coal, I presume, will always be more

destructive in its effects than bituminous; but how much more so can only be

known by experience; this much only is known: that a copper fireplace of one of

the Baltimore and Ohio engines (the first one) has been removed after three

years' service, over 54,000 miles of road, and a copper fire-place of one of

the Baltimore coal engines on the Reading Road (the first one) has been removed

after fourteen months' service, over 23,845 miles of road, which shows their

durability for equal quantities of coal consumed to have been as 1 R. to 1.24

B.&O.

When

the difficulties attending the use of anthracite coal in locomotive engines are

considered in connexion with the entire want of experience with this fuel, on a

scale adequate to the necessities of the Reading Road, it will not be too much

to say that the Baltimore engines have been entirely successful as coal

burners; the term is but comparative, and assigns no limit to the success which

I believe will follow well directed efforts to improve such details as passing

experience shall show to be necessary to insure greater economy of fuel, or

greater durability of parts.

Return to Hopkin Thomas

/ Beaver Meadow Railroad Page

About

The Hopkin Thomas Project

Rev.

January 2011