Manhattan Gateway

UNDER THE RIVERS

Ed. This excerpt (p. 23 – 35) from Middleton’s

excellent work on the development of rail access by the Pennsylvania R. R. to

Manhattan features the construction process which employed cast iron tunnel

rings manufactured by The Davies and Thomas Company of Catasauqua, Pa. J. McV

By

January 1902 planning for the Pennsylvania's great project had already begun,

and the board of engineers was organized and began its work that month. By the

end of the year the City of New York had approved the franchise, and the work

could begin.

Construction

was divided into four divisions, each under the supervision of a chief engineer

appointed from the board. William H. Brown headed the Meadows Division, which

included an interchange yard at the junction with the main line east of Newark

and the line across the Hackensack Meadows to the west side of Bergen Hill.

(Brown was later succeeded by Alexander C. Shand.) Tunneling expert Charles M.

Jacobs was in charge of the North River Division, which included the tunnels

through Bergen Hill and under the Hudson. Electrical engineer George Gibbs was

responsible for New York station construction and the electrification work.

Alfred Noble headed the East River Division, which included the four East River

tunnels and the huge passenger train service and storage yard at Surmyside.

The

distance, the river depth, and the materials through which the tunnels would be

drilled combined to make the Hudson and East river tubes a project of

unprecedented scope and difficulty. But the work was far from the leap into the

unknown that Dewitt Haskin had taken 30 years before: Much had been learned in

the intervening years, and the technology of underwater tunneling was now much

advanced.

Even

though Haskin did not use it, the idea of the tunneling shield had been around

since Marc Isambard Brunel devised one for his Thames River tunnel constructed

between 1825 and 1843. The shield was a cylindrical structure pushed forward by

jacks. as a tunnel was excavated through soft material, supporting the material

until a permanent tunnel lining was put in place.

James

Greathead designed an improved wrought iron shield for the Tower Tunnel

completed under the Thames in 1869; that tunnel was also the first to have a

cast-iron lining. At about the same time, Alfred Ely Beach, an inventor and the

editor of the Scientific American,

used a cylindrical shield propelled by 18 hydraulic rams to drive the first U.

S. shield tunnel for an experimental subway under Broadway in New York.

Shield

tunneling technology reached maturity near the end of the century with the

completion of the Grand Trunk Railway's St. Clair River tunnel between Sarnia,

Ontario, and Port Huron, Michigan. The project combined compressed air support

of the ground during construction, a movable shield, and cast-iron lining.

Joseph

Hobson,

chief engineer for the tunnel, designed a 60ton shield that was moved forward

by 24 hydraulic rains. Tunnel workers on platforms behind the cutting edge of

the shield excavated the river-bottom clay. A rotating arm on the rear of the

shield lifted sections of the cast iron shell into place, where they were

bolted together. Headings were advanced from both sides of the river, and the

6000-foot tunnel was driven in just a year. The Pennsylvania Railroad would use

the same basic tunneling technology.

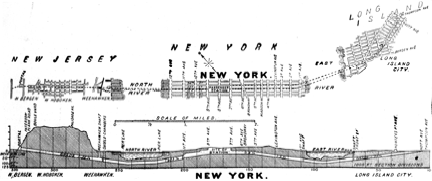

This drawing from the

May 14,1910, issue of Scientific American Supplement shows the alignment and

profile of the Pennsylvania's New York tunnels, from the Hackensack portal in

New Jersey to Long Island City. Science and Engineering Library, University

of Virginia.

The

most challenging portion of the work was the construction of twin tunnels

extending 2.76 miles from the Hackensack portal on the west side of Bergen Hill

to a point under the corner of 32nd Street and Ninth Avenue in Manhattan.

It

was necessary to drill the tubes under the Hudson at a sufficient depth below

the dredging plane established by the War Department (40 feet below mean low

water) to protect them against damage from heavy anchors or sunken vessels, and

to ensure that they could pass below existing piers and bulkheads. The tubes

would also have to be far enough below the bottom of the river to provide

sufficient cover to prevent a blowout during compressed air tunneling.

The

tunnels descended on a 1.3-percent grade from the Bergen Hill portal to a low

point at which the bottom of the tubes was 97 feet below mean high water,

providing an average cover depth of 25 feet between the top of the tunnel and

the river bottom. From this low point, the tunnels climbed for a distance of

5000 feet on grades of 0.53 and then 1.93 percent to level off 35 feet below

street level between Ninth and Tenth avenues.

Surveys,

soundings, and borings confirmed that the tubes would lie in a fluid silt

composed principally of clay, sand, and water. The board of engineers selected

shield-driven, compressed-air tunneling as the most suitable for the work. The

method had the advantage of avoiding any work from the surface that might

obstruct navigation in the Hudson.

The

two single-track tunnels were drilled on 3-foot centers. Each had a circular

cast-iron shell with an outside diameter of 23 feet. Where unusual stresses

were expected, such as a transition from soft to hard ground, cast steel was

used instead of cast iron. Each tunnel "ring" was bolted together

from eleven segments plus a closing "key" segment, each 2 feet 6

inches long and 1-1/2 inches thick. This shell was lined with reinforced concrete

with a normal thickness of 2 feet from the outside of the shell. Concrete

"benches" on either side of the trackway, suggested by Cassatt, were

intended to confine a train to the center of the tunnel in the event of a

derailment. They also served as walkways and provided space for signals.

An

early problem was that of assuring adequate stability of the tubes in the soft

silt of the riverbed under heavy loads. In 1901 Charles Jacobs proposed and in

1902 patented a "subterranean tunnel bridge" design for the crossing

consisting of piers carried to a solid foundation in the riverbed, a truss

bridge carried on the piers, and a tunnel shell surrounding the bridge and

attached to the piers. The bridge structure would carry the live load of trains

directly to the piers, avoiding any deflection of the tunnel. The v truss

bridge scheme was soon discarded in favor of one that called for the use of

shorter girders that would support the track and the trains. They would be

carried on piers spaced at 15-foot intervals.

The

method was tested near the New Jersey bank of the river. The engineers selected

cast-iron screw piles soft ground and then the silt layers under the river,

vary~ ing from 25 to 40 pounds per square inch. Cable-hauled dump cars

operating on 2-foot gauge tracks removed excavated material to the shafts,

where it was lifted to the surface, while flat cars were used to bring in the

cast-iron tunnel segments.

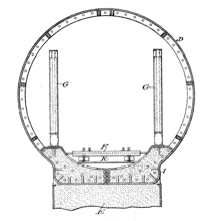

These Patent Office

drawings, reproduced from the February 11 1902, issue of Scientific American,

show the "tunnel bridge" scheme devised by Charles M. Jacobs to

support a tunnel driven through silt or other loose material. The track was to

be carried by steel trusses, which were to be surrounded by the tunnel shell

and supported by piers sunk through the river bottom silt -to rock or other

firm material. Science and Engineering Library, University of Virginia.

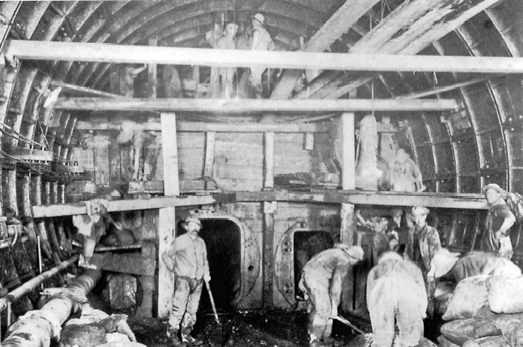

This full-size section

of the Hudson River tunnels was displayed by the Pennsylvania at the 1904

Louisiana Purchase Exposition at St. Louis. Clearly visible are the concrete

benches on either side of the track proposed by A. J. Cassatt. At the bottom of

the tube can be seen the planned track support system carried on screw piles

driven to a solid foundation every 15 feet. These were never installed, and the

openings left for them in the cast-iron tunnel were later closed. Smithsonian

Institution (Neg. 94-4983).

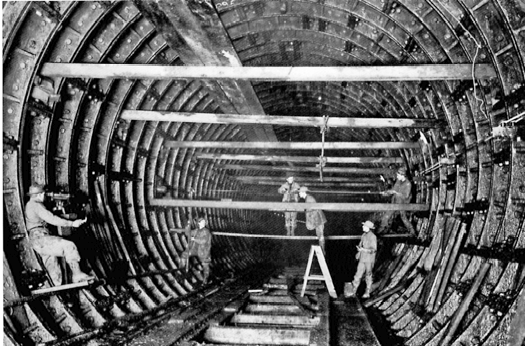

A photograph taken in

the North tunnel on May 17, 1906, shows the 10-foot-thick concrete bulkhead

wall and air locks that separated the pressurized section of tunnel under

construction from the section at lower pressure. Two of these were built about

1200 feet apart in each tunnel heading. This one was installed in the north

tunnel, almost directly below the Manhattan shoreline of the Hudson. Smithsonian

Institution (Neg. 94-4977).

Some

problems were encountered as the tubes pushed out under the Hudson from the

Manhattan side. Where the tubes passed under the bulkhead wall at the edge of

the river, the tunnelers had to bore through pilings and stone riprap

supporting the heavy stone bulkhead wall. As the shield cut into the loose

riprap the compressed air blew out into the ground behind the bulkhead and into

the river. A clay "puddle" - mud made from the excavated silt - was

used to plug the holes in the riprap. Each stone had to be removed individually

by a tunnel worker with a pry bar, while another waited to plug the hole with

puddle.

Each

time the shield was advanced there was a slight "blow" of compressed

air, dropping the pressure within the tunnel. Twice the blow was much greater,

dropping the tunnel pressure enough to allow water to enter the tunnel.

Escaping air created a geyser at least 20 feet high in the river, and water

rose to about 4 feet in the tunnelbefore it could be stopped. For the worst of

these, some 5000 barrels of cement and sand had to be forced through the tunnel

lining behind the shield to bind the riprap together and reduce the loss of

air.

After

making their way through the riprap the tunnelers encountered the wood piling supporting

the bulkhead along the river, and a hundred wood pilings had to be cut out of

the path of each shield. Even after the bulkhead was passed, the loss of

compressed air continued, since there was only a few feet of light silt over

the tunnel. This was finally stopped by dumping 28,000 cement bags filled with

mud into the hole.

As

the tubes advanced into the Hudson River silt, Jacobs expected that the shield

doors could be closed and the shield forced through the soft material without

taking any excavated material into the tunnel, as had been his experience with

the smaller Hudson & Manhattan tunnel he had completed a short time before

between Hoboken and Morton Street in Manhattan. It was discovered, however,

that the shield tended to rise under these conditions, and it proved impossible

to keep the tunnel on the correct grade. Jacobs solved the problem by directing

that some of the shield doors be opened to take in about a third of the

displaced material; this corrected the tendency of the shield to rise as it

progressed. For a time the tunnels even went downward, according to an account

by chief assistant engineer James Forgie, "until it was found they could

be steered vertically by admitting more, or less, silt into the tunnel."

Shown here is some of

the surveying work that helped the tunnelers to work with such precision that

the tubes were within 1/16 inch of perfect alignment when they met under the

Hudson. In this photograph taken on January 17, 1907, the surveyors are

checking line and level through a 6-inch pipe driven between the north tunnel

from the Manhattan side and the south tunnel driven from the Weehawken side

prior to the meeting of the north tunnel shields at mid-river. Hagley Museum

and Library.

It

was also found desirable to increase the weight of the tube to make the weight

of the completed tunnel closer to that of the displaced material. This was done

by increasing the thickness of the cast-iron tunnel lining segments to two

inches. About 2800 linear feet of each tube under the main river channel was

laid with this "heavy iron," adding over 3500 tons to the weight of

each tunnel.

The

tunneling progressed rapidly as the tunnelers gained experience. While it took

as long as 6 hours to erect a single cast-iron tunnel ring in early stages of

the work, this was later reduced to as little as 30 minutes for each ring. The

much more cumbersome "heavy iron" rings were installed in an average

of about I hour 44 minutes. With crews of 24 men at each shield working on

three 8-hour shifts, the average rate of progress in each heading was about 18

feet per day.

The

two shields for the north tube met under the river on September 10, 1906, a

full year ahead of the schedule called for in the Pennsylvania's contract with

the O'Rourke firm. As the two shields came together under the river, they were

stopped about 10 feet apart while a large pipe was driven between them for a

final check of line and level; and it was found that they had met with a

variation of less than 1/16 inch. The tunnelers ceremoniously passed a box of

cigars, representing the first tunnel traffic, through the pipe from one shield

to the other. On September 12, a party of PRR and contractor officials walked

through the tunnel from New Jersey to New York, and Jacobs was given the honor

of "first man through."

The

south tube was completed a month later, and the last ring was installed in

November 1906, after which the work of waterproofing the lining began. This was

done by caulking the joints between the cast iron segments with a material made

up of sal ammoniac and iron borings and by the installation of

"grummets" - rings of yarn smeared with red lead - below washers on

either end of each bolt. This work, followed by placement of the concrete

lining, was completed by June 1909.

The

magnitude of the work is suggested by some of the meticulously detailed records

maintained by the Pennsylvania. Completion of the two 6100-foot tubes under the

river required almost 190,000 cubic yards of excavation, and the completed

tunnels contained almost 67,000 tons of iron and steel, and nearly 57,000 cubic

yards of concrete.

In May 1907, tunnel

workers in the south Hudson River tunnel are shown, to the right, installing

and hammering caulking material into the seams between tunnel segments. The two

men at left are tightening the bolts that held the cast-iron segments together

after installing "grummets" of red-lead-soaked yarn behind washers to

make the bolted joints watertight. Smithsonian Institution (Neg. 944987).

Completion

of the tunnels was celebrated by the engineers and tunnelers in an unusual

manner on June 21, 1909, before the track was laid. A Lozier automobile owned

by Frederic J. Gubelman, vice president of the O'Rourke firm, was lowered into

the tunnel through the Weehawken shaft and driven under the river to Tenth

Avenue in Manhattan. There a party that included Samuel Rea and Charles Jacobs

boarded the automobile for the return trip to New Jersey.

Work

proceeded on the tunnel sections on either side of the river simultaneously

with the tunneling under the Hudson. On the New York side, twin tunnels between

the Manhattan shaft and a portal at Tenth Avenue were drilled and blasted

through rock, except for several hundred feet completed by "cut and

cover" tunneling where soft material was found.

On

the New Jersey side, twin tunnels 5940 feet long were bored through the

traprock of Bergen Hill between the Weehawken shaft and the Hackensack portal.

The tunneling crews worked from both ends of each tunnel, drilling into the

hard rock with Rand "slugger" compressed air drills, then blasting

with dynamite to break up the rock. Typically, tunnel headings were first

drilled and blasted horizontally to form the upper section of the tunnel, and

then drilled and blasted vertically behind this heading on two

"bench" levels to excavate the full tunnel section. Steam shovels

loaded the excavated rock into 3-foot gauge muck trains, which were pulled out

to tunnel portals by 12-ton Vulcan steam locomotives. The hard traprock was

stored and later crushed for use as concrete aggregate and track ballast.

Drilling

through Bergen Hill proved tedious and costly. For every 10 cubic yards of rock

removed, the tunnelers used a foot of hardened drill steel and almost 30 pounds

of dynamite. Even with more than a hundred men working on each of two 10-hour

shifts, progress was limited to anywhere from 2 to 7 feet a day. The first

contract was awarded early in 1905 but the tunnels were not finished until the

end of 1908.

West

of the Hackensack portal the Meadows Division project included 5 miles of

double-track line on a high fill across the Hackensack Meadows to a junction

with the railroad's New York Division main line at Harrison; a drawbridge at a

crossing of the Hackensack River; yard and terminal facilities at Harrison,

where the change between steam and electric motive power would take place; and

a new station named Manhattan Transfer, where passengers could transfer between

trains on the PRR lines to Manhattan and Jersey City and the Hudson &

Manhattan.

To celebrate the

completion of the tunnels, this group of Pennsylvania Railroad and contractor

officials boarded the first automobile ever driven under the Hudson River on

June 21, 1909. Seated in the rear seat, from right to left, are PRR first vice

president Samuel Rea, who was in overall charge of the project; North River

Division chief engineer Charles M. Jacobs; and Albert J. County, assistant to

the PRR's second vice president. Seated in the middle seat are tunneling

contractor John E O'Rourke, on the left, and chief assistant engineer James

Forgie. At the wheel is Frederick Gubelman, the owner of the Lozier automobile

and vice president of the O'Rourke firm. Standing at the right is George B.

Fry, O'Rourke's general tunnel superintendent. Smithsonian Institution (Neg.

84-11044).

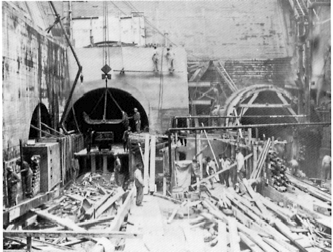

Concrete lining of the

twin tunnels under Bergen Hill was in progress when this photograph of the east

portal was taken in the Weehawken shaft on June 14, 1909. Smithsonian

Institution (Neg. 94-4979).

A

view of rock tunneling in the south Bergen Hill tunnel shows the compressed air

drills used to drill the holes required for blasting and the columns used to

support them. Smithsonian Institution (Neg. 944974).

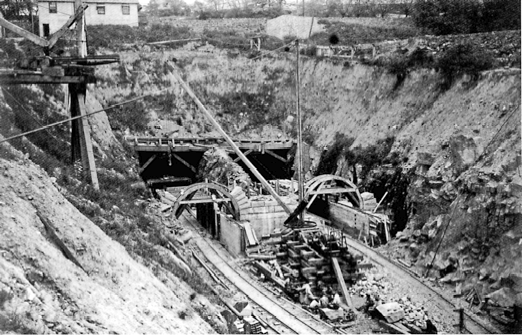

Steam engines were used

to haul Moot gauge muck trains out of the Bergen Hill tunnels. This view was

taken at the Hackensack portal on January 19, 1906. Smithsonian Institution

(Neg. 94-4973).

Another view at the

Hackensack portal, taken a year and a half later, shows the concrete tunnel

lining and masonry portal construction in progress. Smithsonian Institution

(Neg. 94-4988).

The

tunneling problems encountered by Alfred Noble, the chief engineer for the East

River section of the project, were different from those confronted by Charles

Jacobs in the Hudson River tunnels but no less difficult. The railroad planned

a four-track line east of the new Manhattan station to accommodate the movement

of Pennsylvania trains to and from Sunnyside Yard in Queens, the heavy suburban

traffic of the Long Island, and future traffic over the Hell Gate Bridge line.

just to the east of the station the tracks converged into two three-track

tunnels, one under 32nd Street and the other under 33rd Street, each narrowing

to two double-track tunnels a little farther east. Near Second Avenue the

tunnels separated into four individual tubes to cross under the East River to

Long Island City. All four tunnels descended on a 1.5-percent grade to a low

point under the East River and then rose towards the Long Island City side on a

0.7-percent grade. They passed under a Long Island Rail Road depot and yard

before coming to the surface between East and Thompson avenues. The, tracks

continued at surface level to connect with the new service and storage yard at

Sunnyside, the Long Island, and the future Hell Gate Bridge route.

Test

borings begun late in 1901 confirmed that the tunnelers would face a wide

variety of materials and conditions. Much of the tunnel route was made up of

sand, quicksand, clay, gravel, and boulders. At several locations the tunnelers

encountered layers of blue clay and very fine red sand known as bull's liver.

While the material was much firmer than the silt encountered in the Hudson

River, and was not expected to present any support problems, the engineers

expected some hard going in the wide variety of materials. For much of the

crossing, too, there would be as little as 8 feet of fine sand over the top of

the tube, insufficient to prevent a blowout of compressed air.

Because

of the expected difficulties, the engineers considered alternative methods. One

that went as far as an extended test was freezing: A small pilot tunnel would

be driven and the ground around it frozen by circulating brine at a very low

temperature through pipes in the tunnel. The pilot tunnel would then be

removed, and excavation and lining of the full tunnel section would be

completed in the frozen material. To test the idea a 7-foot 6-inch diameter

pilot tunnel was driven 160 feet under the East River and a circulating brine

system was installed. Freezing the surrounding material turned out to be a very

slow process, and the idea was given up when it was found that normal shield

tunneling was going much better than expected.

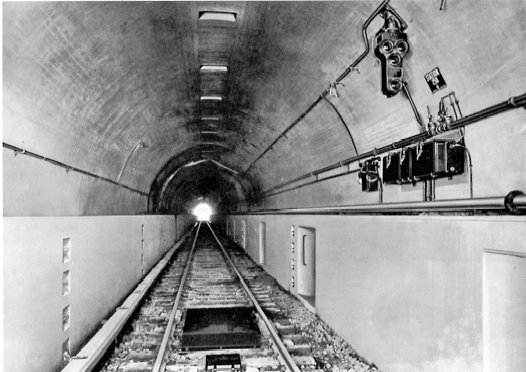

The completed tunnel

looked like this. The concrete "benches" on either side of the track

were designed to confine a train to the center of the track in case of a

derailment, and provided, at the right, a walkway for the placement of signals

and a place for signal maintainers to work safely, and, at the left, a safe

exit from the tunnel. The 675-volt DC third rail is at the left of the track.

The photograph was taken in the westbound tunnel, facing towards the Weehawken

shaft. Pennsylvania Railroad, Trains Collection.

A

contract for all four East River tubes was awarded in July 1904 to S. Pearson

& Son of London, a firm whose previous work included the Blackwall tunnel

in England and some pioneering underwater shield tunneling work on Haskin's

Hudson River tunnel during 1889 and 1890. The tunnels in the contract were

about 6000 feet long, with 3900 feet of underwater tunneling between shafts on

each side of the river and another 2000 feet below ground on the Long Island

City side.

The

four East River tubes were drilled by eight shields traveling east and west

from deep shafts sunk on either side of the river. Almost all of the tunneling

under Long Island City was completed by drilling and blasting without the use

of shields. As expected, there were frequent compressed air blowouts as the

tunnels advanced under the river. "Sudden blows were so powerful that in

one case an able-bodied man was thrown off his feet bythe rush of air,"

wrote Henry Japp, managing engineer for the Pearson firm, "and sometimes,

for brief intervals, it was impossible to make one's way out of the shield

through the doors against the in-rush of air."

"When

Tunnel B passed beyond the Manhattan ferry slip bridge," continued Japp,

"it blew out with such force that mud was thrown over the upper

cross-girder of the bridge, 40 feet above the water level, and one large niggerhead

[a colloquialism for bollard] was thrown out of the water and landed on the

bridge, breaking the decking." The loss of air from the four tubes was so

great that on one occasion, according to Japp, every machine in the compressed

air plant at Long Island City was working at full capacity, putting out at

least 456,000 cubic feet of compressed air per minute.

To

provide a greater depth of cover and control the loss of air, the contractor

dumped clay from barges to cover the line of tunnel with a blanket that

averaged 10 to 12 feet thick. This helped but did not fully solve the problem.

On June 20, 1906, before the blanket of clay had reached the desired depth,

there was a major blowout from the southernmost tunnel on the Manhattan side.

Passengers on the East River ferries heard a roar and then saw a geyser of

water rise 30 to 40 feet in the air as the compressed air rushed out. The crew

of about 20 tunnel workers ran for their lives as water flooded into the

tunnel, but two were drowned.

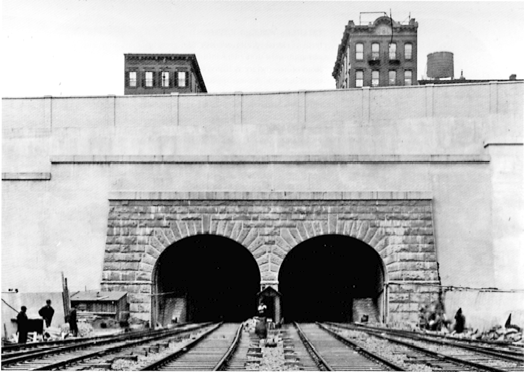

The Tenth Avenue portal

for the tunnels that brought trains into the Manhattan terminal from the west

was faced with a closegrained granite quarried at Millstone Point, Connecticut.

Museum of the City of New York.

"During

severe blows," wrote Japp, "as many as three scows, each containing

600 cubic yards of clay, have been dumped one after the other as quickly as

possible, over the blow, only to be tossed to one side by the escaping

air."

By

this time the causes and prevention of caisson disease - the bends - were well

understood. Decompression chambers and a physician at the work site were among

the precautions taken by the Pearson firm to avoid the bends among its tunnel

workers. Nonetheless, for reasons that were never fully understood, there was

an unusually high incidence of caisson disease on the project. By the end of

June 1906 there had already been 14 deaths from the bends, and a coroner's jury

had returned a verdict censuring the contractor for inadequate precautions.

The

continuing blowouts, the deaths, and a strike for higher pay and shorter hours

by the tunnel workers had the project in disarray.

"One

report had it," said The New York Times, "that there is little chance

of completing the tunnel in less than six years." The sandhogs were soon

back at work, however. The other problems were gradually solved and the

contractor was soon making good progress. On May 17, 1909, the completed

project, comprising some 23,600 feet of single track tunnel and the permanent

Manhattan and Long Island City shafts, was turned over to the railroad.

Construction

of the Manhattan crosstown tunnels between the river and the station site was

carried out from the First Avenue shaft, from two temporary shafts sunk along

32nd and 33rd streets between Fourth and Madison avenues, and from two more

shafts just west of Sixth Avenue. Except for a short section constructed in

open cut, the entire section was excavated by drilling and blasting through the

Manhattan gneiss. Steam shovels powered by compressed air and 3-foot gauge trains

powered by 10-ton electric mining locomotives were used for muck removal.

All

was now in readiness for the installation of the great system of electric

traction that had made the whole New York terminal project possible.

Return

to The Davies and Thomas Page