GENERAL REPORT

UPON THE

INITIATION AND CONSTRUCTIONOF

TUNNEL UNDER THE EAST RIVER,

NEW YORK.

The East River Gas Company of Long Island City was a corporation chartered under the Laws of the State of New York, to supply gas in Long Island City, N. Y. During 1891-1892, application was made to the State Legislature to grant a new and wider charter whereby gas may be supplied from works situated in Long Island City to the City of New York, which rights were granted without the application attracting any general attention.

Mr. Emerson McMillin, President, in the early part of May, 1892, took under advisement the feasibility of constructing a tunnel under the two channels of the East River and Blackwell's Island, between Long Island City and New York, through which the gas mains of the Company might be laid.

Preliminary Investigation.

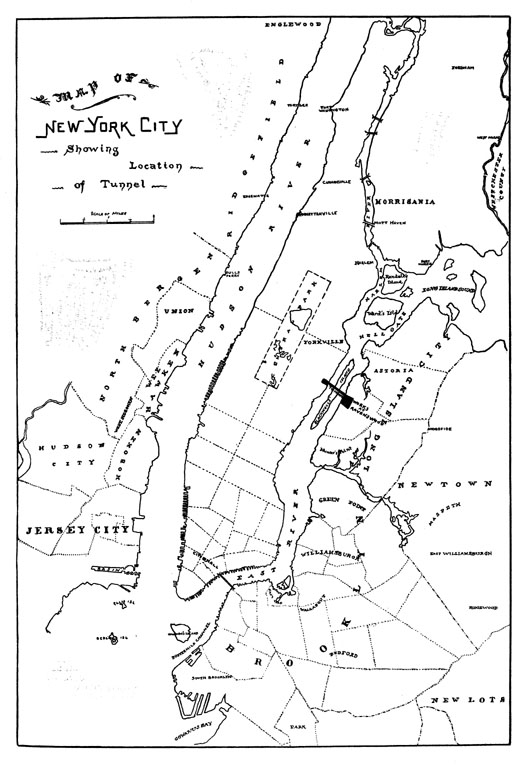

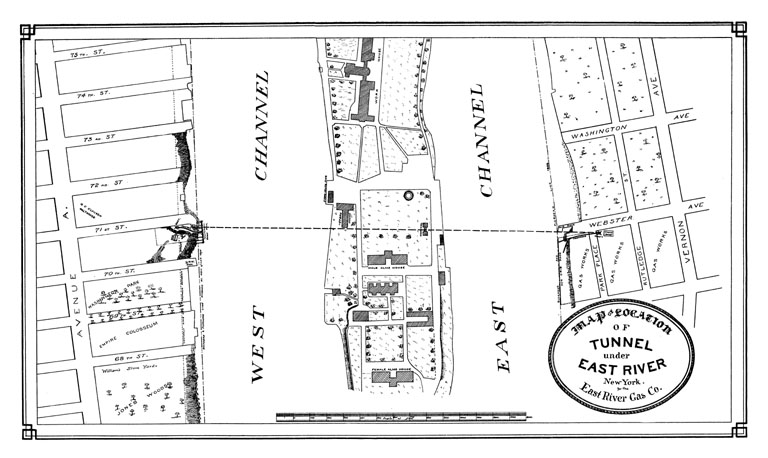

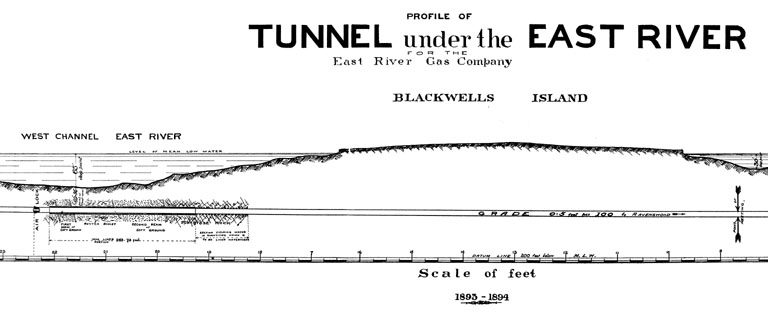

Having been instructed to investigate this question, I immediately instituted preliminary survey and examination between the Company's works, situated at the foot of Webster avenue, Long Island City, and New York. The result of this examination was to determine that the most advantageous route would be from the southwest corner of the then property of the Company at Ravenswood, to between Seventieth and Seventy-first streets, East River, New York, taking the south side of that block as the best location for the New York shaft.

On this line then I directed more detailed examination, and made drill soundings in order to ascertain, as well as possible, the conditions under the bed of the river. The shaft locations on both ends disclosed bed rock a few feet below the surface, and solid rock was visible at the water lines of the rivers, as well as on Blackwell's Island. The current running in these river channels is exceptional, being at spring tides as high as nine knots per hour on flood and ebb tides ; and running with but little abated flow almost until the turn ; allowing only some fifteen minutes of anything approaching still water for each tide, and even then the under current runs later than the surface, so that while it may be still water on the surface, the tide may be running strong at the bottom. It was found, too, that in some localities anchorage was impossible, as the anchors dragged over what seemed to be an almost smooth rock bottom.

It will thus be seen that to make core borings was not feasible, even allowing that such an impediment to the narrow water-way would have been permissible, and therefore it was determined to make drill soundings.

The drill used consists of 2-inch diameter hollow steel rods, having a water-pressure hose attachment at the top end and a hardened steel X bit point with ¼-inch perforations. In still water, any derrick-lifting attachment may be used for the purpose of sounding, as the rods are coupled with inside flush joints in 5-feet lengths. In this case, however, where so short a time is available for a sounding, and, where the depth of water is considerable, it is desirable to use a high floating pile-driver. This arrangement was adopted, and bringing the pile-driver into each position, as nearly as possible, a little while before the turn of tide, gauged the depth of water, coupled sufficient lengths together between the guides of the machine, and at still water brought it up to exact location and made the sounding, using at the time a water pressure of 150 pounds per square inch.

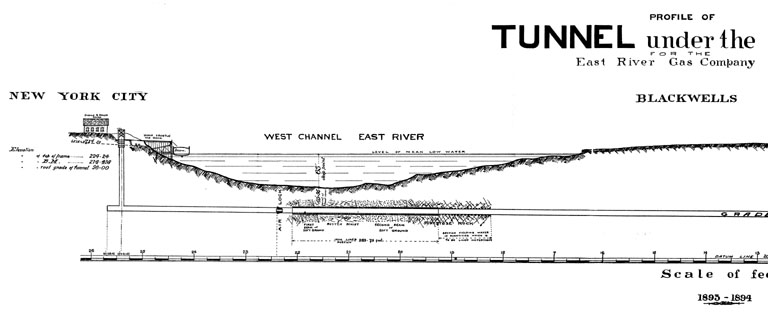

Four soundings were thus made in the east channel and five in the west channel. In the former there appeared to be some two to five feet of sand and gravel overlying the rock ; while in the latter there did not appear as great a quantity. In no case was there any evidence that the drill was striking on any boulder, or anything but solid bed rock, and I concluded that with very little doubt solid rock extended the whole distance across ; and, as an added safeguard, I designed the roof grade of tunnel profile so that the least cover should be 40 feet below the bed of the river, which is itself 71 feet below the level of high water in the deepest part of the west channel ; thus making a total depth of 111 feet between the crown of the tunnel and the level of mean high water at this point.

On this assumption I submitted to the President my report.

I thereupon received instructions to obtain bids on the work, which I immediately did, receiving from Messrs. McLaughlin, Reilly & Co. the most favorable proposal.

Before the contract was awarded it was found that the property on the south side of block in New York could not be acquired on favorable terms, and, therefore, the adjoining plot fronting on Seventy-first street was purchased, and the alignment of tunnel changed to that shown on the map and profile hereto attached, on which the tunnel has been constructed.

The bid of Messrs. McLaughlin, Reilly & Co. was accepted June 15, but the contract was not signed until June 25th, owing to delay arising from acceptance of their bond. Four months after signing the contract, it was considered that the height of heading as arranged would be rather cramped for future developments, and it was determined to increase it from 7 feet to 8½ feet, retaining the original width of 10 feet.

Commencement of Work.

On June 28th, the contractors commenced work on the Ravenswood shaft, clearing away the surface, setting the top sill and excavating the top soil. Bed rock was found at 9½ feet below the surface of ground, and consisted of a very hard, compact gneiss, almost approaching granite.

On the New York side, the property which was required had not been transferred, and we were not put in possession until July 7th, when the shaft was staked out on location back of the proposed exterior street, which is to front on the river. On July 10th the contractors commenced work on this site. Here they had to cut down the high sloping street bank for a shaft-head landing, and had to build up a dry retaining wall from the street to use as a dump-car track. Bed rock on this location was found at about the street grade, and was the regular micaceous gneiss, known as the New York rock.

The contractors were delayed considerably with their work owing to non-arrival of their machinery, particularly the boilers and air compressors.

Work throughout on the shafts was very slow, and the contractors were repeatedly warned to expedite their progress.

The rock in the New York shaft was straight-grained, with dip about 10 degrees off vertical and strike nearly north and south, becoming harder in quality as the depth increased, but throughout of the same formation. No water or difficulties of any sort were experienced in sinking this shaft, the bottom of which, 139½ feet below the original surface, was reached during the week ending October 29th.

At Ravenswood, however, the rock, at all times hard and of about the same kind, was more irregular in formation and seamy. About 25 feet below the surface fresh water was struck, and this constantly increased in quantity as the depth increased. As soon as fissures yielding water were plugged, it would flow elsewhere, and as it found its outlet at greater depths the water ceased flowing above. This water, although tried for a considerable time in the boilers, was most injurious to them, as the carbonate of lime and sulphate of magnesia were excessive, and its use had to be stopped. The difficulty of obtaining fit water for boiler purposes was a constant trouble and source of delay. This water, although not in any degree salt, was quite unfit for use, and the quantity in such narrow limits made the shaft sinking on this side tedious and difficult. The bottom was, however, reached and heading turned during the week ending November 12, 1892.

Instrumental Work.

Great care was necessary in arranging for the alignment of the two headings, as work was to proceed from each end, to meet at some intermediate point ; while the heading, only ten feet wide, was to be worked to its full width, and the small size of the shafts allowed of only an extremely short base line.

Careful triangulation was made determining the shaft centres as 2,516.4 feet apart.

The width of the channels of the river, combined with the inability to obtain equal back sights, made it somewhat risky to use a Y-level to determine the level benches on either side, and therefore resort was had to the level of the river at dead slack water. Float readings were taken on a number of days consecutively at the same moment on either side, and therefrom bench marks were set, from which all grades were calculated and measured down the shafts and through the heading.

The greatest difficulty was in the transference of the heading alignment from the surface to below. The Incurable Hospital building on Blackwell's Island being on the line of the tunnel, the shafts were not visible one from the other. Fortunately, however, the very lofty Clausen malthouse at Avenue A stands on line, enabling a point to be located on the roof thereof, on the extended centre line, from which monuments were set on either side ; and in either case the one back sight was used on the malthouse roof.

Plumb lines were set on either side of the shaft, just over 8 feet apart, and consisted of No. 24 hard brass wire, to which were attached lead weights, weighing about 30 pounds, being as heavy as the wire would carry, these oscillating each in a tank filled with water.

The transit was then taken below and set up in range with the two plumb wires, allowing about two hours for them to settle steady. Permanent points were therefrom fixed on the roof, from which alignment was extended.

This work was repeatedly checked, usually working at it on Sundays, when there would be least interference from and to the men working in the tunnel.

So great was the care taken and accuracy of this work that when the headings met at a distance of 1,678 feet from the New York shaft the centre lines met within ½ inch in direction and less than 1/10 foot in grade levels.

The necessity of the greatest care being exercised in this work, may be inferred from the fact, that an error at the shaft would at the point of meeting on the New York end, have been multiplied over 209 times.

Progress of Headings.

As soon as the New York heading was turned, the contractors prepared their permanent head-house and winding cage and gear, and the heading being driven about 80 feet from the shaft, the shaft-sinking derrick was removed and the cage put in place. On the New York end work proceeded without any hindrance of consequence, until at a distance of 348 feet from the shaft a seam of decomposed rock was struck in the last week of December, 1892. This formation, which will be described hereafter, presented a straight face across the heading. It was perfectly dry, as the fissure, yielding large quantities of salt water (the first water of consequence met with in this heading), had been tapped 28 feet west, and that appeared to take the whole flow of water. This material was as stiff as dry clay and could be excavated with pick and shovel. Acting under instructions, the contractors then drove ahead a narrow heading on the south side about 4 feet wide, thinking possibly we might get past this seam. They were instructed to use timber to support it, although in the narrow heading the ground was quite self supporting. This heading advanced about 9 feet into the soft ground, but unfortunately water made its appearance, oozing through and softening it up. Two days later, on December 31, 1892, the foreman in charge, becoming frightened, took upon himself to build a bulkhead across the face and fill up the hole with timber and hay.

I then determined, if possible, to ascertain what soft ground there was ahead with which we had to deal, and ordered the construction of safety gates in the heading for the protection of the men, and then to open up the bulkhead. By this time some four or five days had elapsed, and, on removing the top planks of the bulkhead, it was found that the water had so softened up thedecomposed ground that it had washed in in quantities, making it unsafe to proceed as previously. I then had a drive-well point inserted horizontally into this ground to test the formation, and found that it came up against solid obstruction at 25 feet from the soft seam. This was presumed to be rock, but was subsequently found to have been a partially decomposed nodule of quartz, rock existing a few feet beyond.

Attempts were made, by the use of pipe laggings driven in close together to carry the roof, to get through this seam ; and using long lengths of 2-inch steam pipe, driving from the south side northwards, a protecting roof was thus made and supported by timber "sets" as material was excavated.

By this time the ground had become of about the consistency of soup, and undoubtedly there was a large cavity formed behind the bulkhead, made evident by the bubbling noise of air in water, and by periodic rushes of water through the face.

It was now evident that, in this way, it was quite impossible to save the heading, and the contractors declined to proceed. They desired that I should authorize the sinking of the shaft, say, 50 feet deeper, and abandoning this heading already completed, drive through at a lower grade. I considered, however, that there was no certainty as to what depth this soft seam extended, and as the present grade was at about the extreme limit of pressure at which pneumatic process of tunneling could be worked, I decided promptly to run no such risk as proposed by the contractors, but to retain the original grade and to install air pressure on this side.

The arrangement now made, after consultation with your President, for the carrying out of the future operations, were: that the contractors should continue to execute all operations under my directions ; that the Gas Company would pay all accounts of wages and for materials required for and used in the tunneling of all soft ground within the air lock, while the contractors for employment of all top men, use of machinery, etc., and for their profit, should receive the full price for the tunnel in accordance with the original contract.

Installation of air pressure.

This arrangement was tacitly agreed to by the contractors, who proceeded to carry on the work in this manner, drawing upon the Gas Company for weekly payments of men, and all orders for special plant required for the air-pressure work were issued from my office and accounts rendered to and paid by the Gas Company.

An air lock was thereupon designed and constructed of steel, 6 feet diameter and 10 feet long, and hitches were cut in the rock heading at 305 feet from the shaft, and immediately on its delivery it was built in with an 8-foot wall of brick and cement, solid to the rock. On February 22, 1893, air pressure was first put on. A couple of days were occupied in preliminary arrangements, and, on February 25th, actual operations were commenced in tunneling under 35 pounds pressure of air. Electric lighting was installed as most beneficial for the men working under air pressure, and a telephone carried right into the face for immediate communication with the engine-room in cases of emergency.

I considered that, from the evidence of the test rod previously driven in, which indicated only some 25 feet of soft material ahead, it would not pay to go to the expense of construction of a shield, and that brickwork circular lining would answer every purpose.

On breaking through the bulkhead, however, we found that the material which had originally been firm and stiff, had, under continued erosion, attained a souplike consistency, and that a huge cavity some 4 feet wide and 26 feet high had been washed out up towards the river bed. This at once explained the reason for the previous flushes of water and the curious bubbling sounds.

Using a centre sill with heavy timber bracing and laggings, and barrel staves for poling boards, and keeping the bulkhead short lengths ahead, we proceeded with excavation, lining the tunnel as we advanced with light wrought-iron plates connected by angle irons, and inside with 12-inch brickwork, carefully packing the cavity before mentioned with hay and debris. This was an extremely difficult piece of work. The heading in this ground was enlarged and made a true circle, for the purpose of obtaining the greatest strength in construction, the outside diameter being 12 feet. On February 28th, in order to check the inflow of water and squeezing of ground, the air pressure was raised to 37 pounds, and therewith the first difficulties arose from sickness. This increased, as the pressure was further raised to the very high figure of 48 pounds per square inch. These difficulties were caused and aggravated by the necessity of employing "green hands" on the work. The "hard times" had thrown numbers of men out of employment, all anxious to obtain work at any risk, and particularly so in view of the high rates of wages and the short working hours. In addition to this, the regular air-pressure men had not been accustomed to work in as high pressure, and were out of condition, or, to greater or less degree, suffering from the effects of free living.

Our first fatality was the case of Edward Ferris, foreman, who, on March 4th, succumbed to the pressure and died half an hour later.

The second occurred on March 10th. Louis Doran, who having, as was afterwards learned, been long out of employment and in very low condition, and after having been specially warned as to the danger of the work, expired in the air lock in coming out after his first "shift" of two hours.The third, Theodore Morris, a bricklayer, on March 16th became paralyzed from the shoulders down, and died shortly afterwards.

No other deaths occurred for nearly a year, when, January 2, 1894, the fourth and last death, that of Thomas Crimmins, took place, as the result of this peculiar disease.

In view of the enormous pressures worked under, the Company has every reason to congratulate itself on the low death rate.

Sickness of Employees.

Our very best thanks are due to the Medical Staff and Directorate of the Presbyterian Hospital at Seventieth street and Park avenue, for the ready and able assistance they have throughout rendered us, in the investigation of the causes and effects as well as in the treatment of the men sent to the hospital suffering from the "bends."

Shortly after commencing this pressure work, Dr. Andrew H. Smith formulated for us the following notice to employees as to their conditions for working under pressure.

RULES FOR MEN.

1. Never enter the air lock with an empty stomach.

2. Use as far as possible a meat diet, and take warm coffee freely.

3. Always put on extra clothing on coming out, and avoid exposure to cold.

4. Exercise as little as may be during the first hour after coming out, and lie down if possible.

5. Use intoxicating liquors sparingly. Better not at all.

6. Take at least 8 hours sleep every night.

7. See that the bowels are open every day.

8. Never enter the air lock if at all sick.

9. In exit from the air lock, the time occupied is to be : five minutes for each atmosphere above the normal.

Investigation by the medical staff leads to the conclusion that the earliest injurious effect in a healthy subject is itching, caused by air globules in the capillaries. This may be quickly cured by inducing profuse perspiration.

Secondly, "bends," which is an intense rheumatic pain in the joints, caused by air globules in the sockets ; may be benefited by profuse perspiration and immersion again in a heated pressure chamber.

Lastly, paralysis, which leaves lasting injury, and usually is the cause of death when such occurs.

Any person having any disease of the bronchial tubes, lungs or heart has no right to enter pressure.

We have found throughout the greatest benefit from a highly steam-heated dressing-room and the copious provision of hot strong coffee for the men.

The hours of employment, too, under air pressure have required to be strictly regulated by the pressure under which the men were at work. For pressures up to 30 pounds above the atmosphere, the men will work for nine hours, taking one hour off in the middle, making a working day of eight hours. For the highest pressures worked, however, only one and a half hours at a time is allowed in pressure, with one hour rest between, and combining to make only four and a half hours actual work per day. This is the case only under the maximum pressure which was used.

Progress of Headings.

To return again to the work in the New York heading, in which the material was so soft as to be only workable with the greatest difficulty, and in front of tight bulkheads. All proceeded well, but withal necessarily very slowly, until Sunday afternoon, March 26th. In order to keep an exact record of the air pressure maintained I had fitted up an Edson automatic recording pressure gauge with high and low pressure alarm bells attached. Happening to proceed to the shaft I discovered the foreman, employed by the contractors, with the engineer, had broken open the lock of this gauge and had removed the pencil from the indicator. The fires in the boilers were nearly out and the air compressor stopping. Investigation showed that the engineer and fireman had been drunk and allowed the fires to burn out, and the pressure in the heading had dropped 11 pounds. A large quantity of the soft ground had washed into the heading, and we feared at first that very serious damage had been sustained. A diver's examination of the bed of the river proved that it was intact, and no "cave" had occurred from the river bottom itself. It was with the greatest difficulty, however, that this short length of 6 feet was worked through to rock, by means of steel tipped lap jointed oak poling boards, driven into the rock ahead ; as a great cavity above had washed in, and the quantity of water yielded was bringing it down continuously.

On April 8th, this was closed up and the last section of brickwork keyed.

The rock ahead was now very soft, seeming in the early stages of decomposition, and yet strong enough to be self-supporting, and the heading was progressing into it.

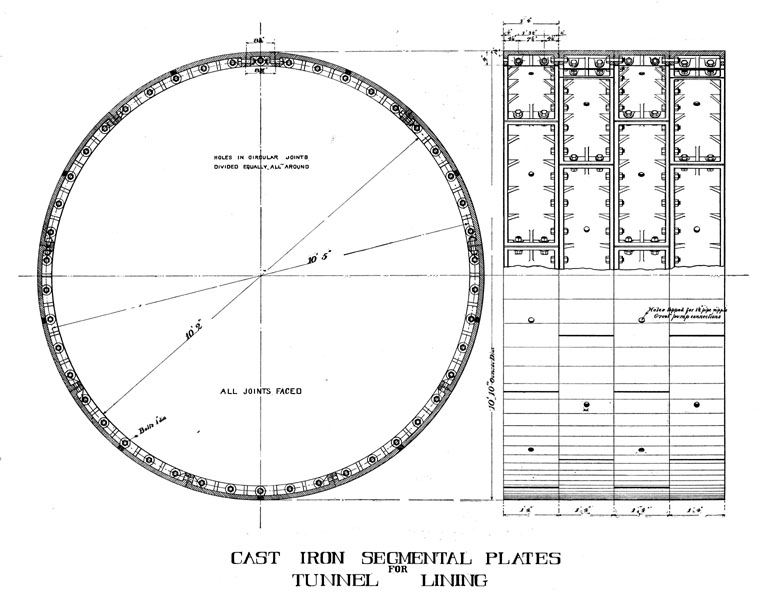

On April 28th I had the air pressure entirely removed and took the contractors into the heading, pointing out to them the face of rock ahead, and requested them to take charge and carry out their contract. At the same time I found that, now the air pressure was removed, the seepage through the brickwork was considerable- that it would be advisable to back this with face-jointed cast-iron plates. The size of the brickwork and heading completed, limited the diameter which we were able to make these plates, and I found that by cutting away some of the brickwork piece by piece, and inserting plates having flanges deep enough to stand the strain, that we could obtain an inside clear diameter of 10 feet 2 inches, as shown on drawing of plate lining.

These I at once ordered from Messrs. Davies & Thomas, they being the lowest bidders.

Abandonment by contractors.

Following hereupon came the troubles between the Gas Company and Messrs. McLaughlin, Reilly & Co., which ultimately resulted in the suits at law tried in the United States Circuit Court, in New York City, before Judge Shipman, in January, 1893.

Having driven beyond the first seam of soft ground 69 feet into the rock, the contractors were notified to continue their contract. This they declined to do, claiming to carry out the future work on force account, adding 10 per cent. commission to themselves, and rendering an account on that basis for the work executed since January 1st, when soft ground was struck. This arrangement your President very rightly declined to allow. The contractors then ordered the air compressors to be stopped and their plant removed. As this would be a most serious matter, in view of the fact that during the intervening period we had discovered another seam of soft ground ahead, your counsel obtained an injunction from the Courts on May 31st preventing that course and allowing us time to make all secure and fit up our own plant.

The contract having thus been terminated and the contractors dispossessed, I arranged to organize our own force to carry out the work and to purchase our own supplies.

Ravenswood Heading.

Up to this time work had proceeded very irregularly at the Ravenswood end. Bad water and insufficient supply for the boilers caused constant suspension of work, and owing to the volume of water met at that end increasing, any stoppage of pumping plant caused drowning out of the shaft and heading.

At 253 feet from the centre of Ravenswood shaft we met the first soft ground, which was a narrow seam some 8 feet wide, yielding no water, and so caused no interruption to the work ; then followed about 10 feet of schistose rock, another seam of about 8 feet of soft ground, and again schist, of which we took out about 7 or 8 feet. On drilling into this rock about 2 feet, there was struck at 285 feet from the shaft a green, slimy and almost liquid material, which flowed out of the drill holes. It was necessary to know what was ahead, and the contractors seeing that there was over 100 feet between the tunnel roof and the bed of the river, expressed complete confidence in being able to get through with their present methods, using timber sets and bar laggings. As a safeguard a bulkhead was built 10 feet back from the face and the rock blasted out. After repeated attempts on the part of the contractors to control this material and make progress, they abandoned the work in the latter part of March, allowing the heading and shaft to fill with water, and no work was further done on that end by the contractors.

"Hard times."

The summer months of 1893 will long be remembered for the disorganized condition of the financial world and for the extreme difficulty of obtaining money, and at times the almost impossibility of getting currency to pay the wages of employees.

It was therefore not only advisable, but absolutely imperative, to curtail every expense. Your directors desired, however, that we should continue to proceed with the work on the New York heading on day shifts, and as the Ravenswood end was then in a practically abandoned state, that all our expenditure should be concentrated on the New York side.

This time, during June and July, was taken advantage of in lining the brickwork already put in with cast-iron plates, behind which grout was pumped at 100 pounds pressure, making a perfectly water-tight job on removal of the air pressure.

New York Heading.

Proceeding with the New York heading, the remaining 8 feet of rock was taken out up to the second seam of soft ground, and a test rod driven ahead disclosed nothing solid at a horizontal depth of 70 feet. We prepared to work this seam in the same manner as the last, and had advanced a few feet ahead, when, on August 8th, the hopeless stringency of the money market compelled your Board to order complete cessation of work. This was most unfortunate, coming at this particular time, since it permitted the water to soften up and erode this soft ground ahead. No work was therefore done on this side until September 30th, when examination showed that it would be necessary now to install a hydraulic shield to advance with speed and safety.

Hydraulic Installation.

The steel shield and hydraulic pressure plant were at once ordered, but it was not until November 25th that this was ready for operations.

This long stoppage of three and a half months had done considerable damage, and, commencing work, we found a long shelving bank of rock at the bottom of the shield, while at the top was the softest kind of black mud. This was the time of the greatest anxiety, difficulty and risk in the whole work. It was necessary to blast out the rock in the floor in advance of the shield and to get through the bulkhead which had been put in when the work was abandoned. Beyond this, direct communication was made with the river, through which came into the tunnel refuse from the river bed as well as live crabs. The leakage of air was so rapid that both compressors running at their maximum speed could barely maintain the pressure of 48 pounds which was needed. This pneumatic pressure is the highest which it has ever been known that men have worked under in tunnel operations, and is equal to the full hydrostatic head at the depth to which work was then being carried out, and it was only wise or possible to work the men for no longer than one hour and a half at a time.

This pressure and the difficulties consequent lasted until the shield was fairly entered into the black mud, when pressure was reduced and fast work was done, advancing and lining six feet per day.

It is of interest to note that the hydraulic shield was forced forward by twelve jacks, under a water pressure of 5,000 lbs. per square inch, which, distributed over the entire structure, was equivalent to a weight of six hundred tons.

This second soft seam extended in all 98 feet, and was completed and lined on January 16th. The rock ahead was of a bad seamy description, yielding quantities of salt water, but gradually hardened up and became solid. Some 65 feet, however, required lining with plates, and that portion of bad rock between the first and second seams was also lined up and grouted, making a continuous plate-lined length of 283 feet.

From this point on, no difficulties of consequence were encountered. The rock, which was unmistakably the same as is found on Blackwell's Island, changed in character from time to time, but was sound, and after getting under the shore of Blackwell's Island, yielded only very small quantities of fresh water.

The rapidity of progress from this on until the point of meeting was great ; and during two weeks, when 101 feet, and 94.6 feet advance was made, has never been surpassed in this class of rock.

Fire.

Serious loss and delay was occasioned to this end of the work on May 16, when about 2 A. M. the picnic park, known as Jones' Wood, caught fire on the southwest end. A high southerly wind prevailing, caused the fire to spread with lightning rapidity over the light wooden. buildings on those two blocks, and then, although on first evidence of fire our fire hose had been put in play, to soak our light frame buildings with water, yet the fire passed over the half block vacant intervening and set fire to our plant. The whole place was a hopeless ruin within an hour. Notes, records, photographs and instruments, as well as the plant, was destroyed.

By hiring portable boilers it was hoped to keep the water pumped out, but these failed and the heading was drowned out.

It was 18 days before any work was done in the heading but in reality this delay was a loss of fully four weeks in the final completion of the work.

Ravenswood Heading.

Between March 11 and May 31, when the contractors gave up the work, but little had been done on this end. The contractors had cut hitches in the rock at 255 feet from the shaft in which to build the air lock, and had prepared everything for putting it in place. Subsequent to their leaving, the shaft, which had filled up through failure of steam during the period of the injunction of court, was pumped out, using as our steam supply the permanent boiler plant of the Gas Works which was connected for us. The air lock was put in place and pressure put on on August 14, 1893. General examination was made and it was found that a huge cavity of considerable width inside of the rock face had been washed out, extending a couple of hundred feet northwards and high up towards the river bed.

No work was done at this time owing to the order to shut down on the work, and the heading was left in as good condition as was possible, to await such time as might justify further procedure.

When, in December, 1893, general orders were issued to push the work in every possible manner, it was considered that at that time no advantage, in completion of the work, would be gained by ordering a second shield for this heading. In view, however, of possible unforeseen occurrences delaying the attainment of the shield in use on New York heading beyond the time calculated upon, and also having regard to the great importance of expediting the work, your Board decided to have a duplicate shield and hydraulic plant ordered at once for this side. This second shield, in which some slight improvements, suggested by the use of the first, had been made, was delivered and installed ready for work.

The water in the river, above the place where the great cavity above described existed, was only some 12 feet deep, below that being gravel, sand and boulders. When air pressure was put on it was noticed that with only 10 pounds the air commenced blowing out at the surface, and when raised to 38 pounds (which was the pressure at which work was carried on on this side, air bubbles were visible up and down the river for some 500 feet either way, indicating that the water actually lying above the cavity could not exceed some 24 feet depth, while the fissure, from which more or less material had been washed into the heading, must extend at least some 1,000 feet.

This first seam of soft ground, which proved to be 38 feet through, presented no especial difficulties, but necessitated extreme care in tunnelling.

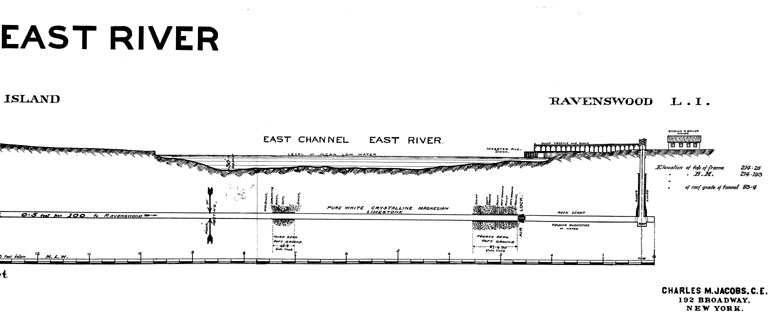

The heading beyond this proceeded at very rapid rate, through, for the most part, a pure white spar, soft and easy to work, in which progress was easy and regular, and a square heading could be driven. As much as 98 feet in one week was driven in this material.

During this period the sound of blasting could be heard in the other heading, though not very distinctly, but no sound of drilling. It was hoped that no more soft seams would be met. On May 21st, a fissure yielding large quantities of water was struck, the rock having been rapidly changing in character for fifty feet back. So great was the influx of water, that we had at once to put in a larger pump to handle it, and as soon as that was done work proceeded rapidly under about 35 pounds air pressure.

This seam appeared to be the extreme bottom of another soft decomposed measure, and lining with segmental plates and carefully packing and grouting them, and proceeding cautiously, work was carried on through this seam without the re-erection of the shield, which would have delayed the work. Very shortly beyond this point the rock heading struck the same Blackwell's Island rock being worked from the New York side, and, moreover, the sound of drills was now distinctly heard.

Having advanced the heading to this point, I considered it the best policy to return and clear up and make more water-tight the work already executed, and on this operation a week was spent very profitably.

On July 11, 1894, the measurement proved there to be 21 feet only remaining between the faces, and the greatest excitement prevailed among the men. At seven o'clock that evening the first drill was put through from Ravenswood to New York, fair in the middle of the heading, and at about midnight of that day, the wall was blasted out and the headings met at 1,676 feet from the New York shaft ; and those present walked through from New York to Long Island City by way of the pioneer tunnel under the East River.

Comparative progress.

The original contract with Messrs. McLaughlin, Reilly & Co. called for the completion of the tunnel by April 11, 1893. As before mentioned, they commenced work on the Ravenswood shaft on June 28th, and turned the heading November 12th ; an average rate of progress throughout of only 7 feet per week, and a maximum progress during that time of 10½ feet.

The New York shaft was commenced July 10th, and completed October 29th, making an average rate of progress of 8 8/10 feet per week, and a maximum weekly rate of 15¾ feet.

In the Ravenswood shaft quantities of water were met with, and bad feed water for the boilers caused delay ; but at New York there was absolutely no set back, no bailing or pumping, and a sound rock with vertical stratification made everything fair, and yet in both cases the progress was extremely slow. Their slow progress on shaft sinking allowed the contractors only 22½ weeks in which to drive the 2,516 feet of heading, which would therefore require a weekly progress, for each face, of 56 feet to get through on time.

In the New York heading up to the point where the soft seam was met (viz.: 348 feet from shaft), there was no water of any consequence struck, and the rock was throughout sound and good to work.

The progress, however, made, averaged during this period 40 6/10 feet per week, and the maximum amounted to 57½ feet in any one week.

At Ravenswood heading, the progress made by contractors, excluding about 3 weeks when boilers and pumps failed on them, averaged only 20 3/10 feet per week, and the greatest in any single week amounted to 40½ feet.

At such speeds of driving as these, it would be evident that, had the formation been solid rock throughout, the contractors would have failed to complete the work within the time contracted for, and would therefore have been liable to the penalty of $100 per day forfeit as contracted.

Apart from the progress made while working under air pressure and in soft ground, our own construction force have improved on these amounts. The force at the Ravenswood heading, when working in rock, have made an average rate of progress of 69 feet per week, with a maximum single week's rate of 94 6/10 feet.

The New York force made an average record of 69 feet per week, while as before mentioned they made a single week's record of 101 feet.

(These figures of course exclude the time lost in consequence of the fire destroying the plant.)

In accordance with the instructions of your President, no expense has been spared in order to attain these high results of progress, and the system of paying bonuses on fast work to the foremen, and at times also to some of the gang leaders, has been carried out and found to give very excellent results. Taking into consideration the importance to your Company of having the heading completed early, this increased cost of driving will be amply justified. The difference in the results attained by the original contractors and by our construction force are so marked as to demand special notice.

Geology.

It is of considerable interest to study the peculiar geological formations met with in this work. The two channels of the East River divided by Blackwell's Island are looked upon as forming the ancient valleys of a double glacier, which, flowing across from the Hudson Valley by way of the Harlem, divided on the north end of Blackwell's Island.

The rock as seen on the surface at all points is of metamorphic origin, and is throughout gneiss and schist, but that on New York shore, on Blackwell's Island and at Ravenswood are quite unlike. At the west end the rock is the regular comparatively soft, highly micaceous gneiss.

On Blackwell's Island it is a hard, close and straight-grained variety, with considerable mica ; while at Ravenswood it is extremely hard, more massive and in as far as breaking is concerned, practically equal to granite.

It is then to be expected that there would be changes in the formations which would be met, particularly as the dip is uniformly about fifteen degrees east of vertical, the strike nearly due north and south, and the direction of the heading is nearly due east and west, thus crossing the measures nearly at right angles.

Preliminary soundings disclosed the fact that in the West Channel, the deep channel is nearly the centre of the stream, and that so far as we were able to discover, rock was continuous over the whole bed, having only a couple of feet of gravel boulders overlying.

In the East Channel, however, the water nowhere is very deep. The west bank slopes down apparently more precipitately, making the deepest point of the river near the westerly shore, while the bed is flat for considerable distance across. On this bed was found seemingly some three to six feet of gravel with boulders overlying rock. Rumor had it, that in old days the deep channel was close to the easterly bank and had at some time been filled in. There is little evidence, however, for this statement.

In the New York shaft the rock below the surface rapidly became harder and closer grained, but remained essentially the same in character to the bottom, and no fissures yielding water were met.

The Ravenswood shaft proved the rock extremely hard throughout. Veins of pure quartz were met constantly, and the fissures, of which there were large numbers, yielded considerable quantities of fresh water, which later became brackish and salt.

Starting from the west end and moving eastward the rock remained the same for 300 feet, except that at times it was harder or softer than at others, and occasionally narrow fissures, or mud seams, were met. Here, however, the rock became more highly micaceous and rotten, and at 321 feet a fissure was met yielding large quantities of salt water. There was immediately at this fissure complete change.

First seam of soft ground, New York end.

The rock, which had hitherto been regular in stratification, became an irregular micaceous schist. At 348 feet this gave place to a straight face, 15 degrees off vertical, with north and south strike, of soft ground. The record obtained of this seam proved as follows : 9 feet of soft, white decomposed feldspathic rock, which, although as soft as cheese, retained its nearly vertical stratification shown by lines of decomposed black mica and garnets, which in working, gave a gray appearance to the material. This was a kaolinized vein of pegmatite.

3 inches vein of hard quartz.

6 feet, more or less, of pure white, decomposed feldspar, perfectly smooth and soft. This was also kaolinized pegmatite.

8 feet of soft, gray and green stratified material ; being a decomposed band of mica schist.

6 feet of green chlorite schist, having an appearance and feel similar to graphite, and throughout these last formations were nodules from a couple of inches to a couple of feet diameter of quartz, partially decomposed, leaving the hard portions like a skeleton when cleared of the soft parts. This was a decomposed band of excessively micaceous schist.

In all this soft decomposed seam measured 29 feet across.

The rock which followed could in no way be called hard. It is evidently in the early stages of decomposition, and a considerable portion was capable of being broken away with picks without use of explosives. This is a schistose formation, being white and green in streaks. Of this there exists 80 feet. The fracture appears always along the planes of the green chlorite thus leaving the soft white spar like a sandwich between green faces.

Second seam of soft ground, New York end.

This formation gave place to a completely decomposed formation again at this point. A horizontal test pipe driven in, from which the samples were obtained, indicated-

7 feet white feldspathic decomposed rock. 5 feet soft black mud having with it lumps of completely carbonized black wood resembling lignite.

2 feet coarse river sand with pyrites in large quantities.

5 feet sand and black mud with the same lignite formations, and the mud having all through it small cavities about the size and shape of a walnut filled with balls of pyrites evidently crystalized in place, for the facets of the crystals were perfectly formed in place, and there was no rubbing evidenced.

22 feet soft white decomposed feldspathic, in which were irregular lumps, as referred to before, of partially decomposed quartz, and these lumps appeared in every case to emit a very strong odor of sulphuretted hydrogen (foetid quartz).

4 feet green and white streaked.

11 feet soft white feldspathic.

42 feet completely decomposed greenish material, apparently being a decomposed schist.

The general derivation of these rocks is the same as is stated above for the first soft seam ; except in the case of the sand and mud, which evidently fill an old pothole or small gulch.

The evidence of the test pipe was borne out subsequently in tunnelling, except in the earlier mentioned parts, for in excavating it was found that the harder rock shelved off at an angle of about 45 degrees, so that while the floor of the tunnel was still in rock, which required drilling and blasting, the roof was already entered into the black mud mentioned. This mud, after water had got access to it, became like soup in which the lumps of carbonized wood floated about. These pieces of wood looked as though they were short, detached sections of a small tree. It was through the washing in of this mud that the great trouble was experienced when direct connection was made to the riverbed.

All the formations making up this soft seam appeared to maintain the angle of stratification, same as the limiting rock.

Following on this came again unsound mica schists and gradually again into gneiss rock, at first full of fissures and seams and thereafter the solid Blackwell's Island rock.

A point worthy of note occurs in this rock at from 150 to 250 feet east of the west shore line of Blackwell's Island, where the rock is of such intensely hard class that it was with the greatest difficulty that drills could be got to cut it. This section seems to be under some intense local stress, that from time to time, even six months since opening it, gives out reports like a pistol shot when the strain cracks the rock, and from time to time masses of it fall in without warning. It is only this single short length where any such thing occurs, and it is now protected by arching.

There was no other feature of note, until out under the east channel of the river about 260 feet from the east shore of Blackwell's Island. There was encountered what appeared to be the extreme bottom of a soft seam.

Third seam of soft ground, Ravenswood end.

At this point there exists something like 90 feet between the river bed and the tunnel. Still, going from the west eastward, the regular stratified gneiss gave place to mica schist, then to some 10 or 12 feet of dolomitic limestone, while the stratification seemed to be flattening ; then came again an extremely faulty mica schist having clay clods lying between the joints, arising from disintegration in the folding surfaces. This schist, at first lying with flat dip eastward, became horizontal, having soft green decomposed chlorite schist high up on the roof, then folded up with a dip westward, and after some 50 feet of this mica shist succeeded a bed of pure white crystalline rock having a westward dip of about 15 degrees off vertical.

The presence of this formation is most interesting. It is a dolomitic limestone, in crystalline condition folded, in between the mica schists of which, as mentioned, the main body occurs at this point while the then folded end appears to the west of the third soft seam mentioned above.

Fourth seam of soft ground, Ravenswood end.

This formation extended about 150 to 160 feet, giving place again to mica schists, then again to a soft seam. This soft seam, similar to those on the New York side, was 30 feet through from rock to rock, consisting in part of white feldspathic material, but principally of the decomposed green schist, having quantities of the partially decomposed quartz lumps in it.

Following this, a narrow schistose rock seam. Then a narrow decomposed green chloritic seam, another schistose rock seam and another soft green chloritic seam. Then schist again, and finally the hard, straight-grained Ravenswood rock at a point inside the bulkhead line of that shore.

It will be particularly noticed that though the rock varied considerably in texture and degree of hardness all the way through, yet it was the same rock from end to end, but that in every case where a soft seam was encountered of this completely decomposed character, that it was bounded both east and west by a formation of schistose rock, seeming to indicate that at the points where local strains had so changed and broken up the rock, it had so permitted the access possibly of sea water or other chemicals in solution to set up this remarkable decomposition strictly within these schistose boundaries. The abundance of easily decomposed dark mica, or biotite, also aided the change. The other formation of note is this deposit of white crystalline magnesian limestone between the schists and by upheaval folded back and squeezed out as described.

This work, which at first investigation had appeared to my best judgment a simple undertaking, requiring patience, skill and ordinary care, has in consequence of these peculiar and quite unexpected geological formations developed into one of considerable engineering difficulty and magnitude.

It should be noted in this connection, that at the time soft ground was originally met with, the clear diameter of the lined portions was calculated and arranged to give an area exceeding that of the original designed cross section in rock. The cost of iron plates for lining the heading in soft ground increased the total cost much beyond the amount which would have been required if brick lining had been continuously employed. This increase in cost is amply justified in the greater strength and as an economical means of stopping the flow of water. It is also to be remembered that during the most difficult portions of the work, any failure of any part of the machinery, or loss of steam supply, would have been fatal not only to the work, but to life itself, and it is matter for congratulation that no such accident should have occurred ; amply justifying the expenditure in duplicating the air compressors, and maintaining heavy margin of boiler and pumping power.

Risk to life, which in every tunnel operation is considerable, was vastly increased owing to the greatly augmented dangers of work under high air pressure. Yet our death-roll amounts only to four lives ; and in view of the fact that in the rock work large quantities of nitro-glycerine compounds were used, not a single accident of any kind occurred to employees during the whole progress of the work. It has from first to last been to the laymen a great uncertainty. The troubled financial times, which happened to have fallen upon us during the progress of the work, seriously delayed the completion and added to the intense anxiety of those responsible for its success, who having put faith and money into the great scheme, were unable to see whence would come the return. In those days it was that Blackwell's Island seemed to be ever receding as the heading advanced.

By courage, skill and patience this tunnel is to-day un fait accompli, and Ravenswood is one with New York.

The 36-inch diameter gas main is now laid in place, and a three feet gauge railway track alongside it, so that if at any time desired an electromotor car can transmit passengers between New York and Long Island within two minutes.

In conclusion, I desire to express my high appreciation of the confidence reposed in me, by the President and Directors, in granting me at all times, unstinted support in the administration of these operations, which has been a great factor in the safe conduct of the work.

In this work I owe thanks and praise to Mr. J. V. Davies, who has been my principal assistant from the first incipiency and has carried out personally the whole of the instrumental work, and in my absence has carried out the general direction of the work on my behalf.

To Mr. W. I. Aims, whom I engaged on the first installation of pneumatic pressure and has had charge of that work throughout and until the completion, as Assistant Engineer in charge.

To Mr. G. B. Fry, who has acted as Superintendent of Rock Work and has proved his ability in that branch by the excellent results he has attained.

To Mr. P. Fitzgerald, who has been senior foreman in charge of all air pressure work, and to whom the greatest credit is due for his ability, readiness and attention in the most awkward circumstances.

And lastly, to every man who has loyally stood by me through hard times as well as good and has each in his own way best assisted towards the one end.

Respectfully submitted,

CHARLES M. JACOBS, Chief Engineer.