The Davies and Thomas Company

Excerpted from Burkhardt and Gemmel, A Profile of the Burroughs,

Catasauqua, Lehigh County, Pa.

Davies & Thomas Foundry – Race Street 1914

Among

the industrial organizations that brought fame and fortune to Catasauqua was

the Davies and Thomas Company. This company had its origin in 1865 when Daniel

Davies bought an old planing mill in Catasauqua and fitted it up as a grey iron

foundry and machine shop. Davies had as a partner, William Thomas, who remained

with the business for two years before returning to Wales. After this, the

business continued as Daniel Davies and Son until the death of Daniel Davies in

April, 1876.

Because

of poor business conditions, the works were shut down until 1879 when a second

partnership was formed with George Davies (son of Daniel) and James Thomas as

principals. The company did general foundry and machine work, produced vertical

and horizontal engines, car castings, and appliances for furnace mills and

mines. The plant covered twenty acres beside the Catasauqua Creek, on which

stood a number of buildings. Five vertical engines supplied the power.

Employees numbered approximately two hundred. By 1913, the foundry occupied 16,000

square feet of floor space and was equipped with electric and boom cranes and

four cupolas. There were three fully equipped machine shops. A large power

plant with a boiler and an engine room had been built for the manufacture of

electricity to run the entire plant. The plant had a capacity of two hundred

tons per day of finished castings. When fully operational, the plant employed

over six hundred men.

George

Davies died on October 1, 1894. In December of that year the firm of Davies and

Thomas Company was organized into a chartered company with James Thomas as

president. James Thomas died in December 1906 and his son Rowland D. Thomas

succeeded him as president. In 1911, Leonard Peckitt assumed the presidency. In

1923, while the company was engaged in making castings for the construction of

the Holland Tunnel, the general contractors of that project, G.H. Flin

Corporation of New York, came into control of the Davies and Thomas Company.

They installed S.M. Rutladge as president. Later, ownership changed again when

the U.S. Pipe and Foundry Company of New Jersey acquired control. They

appointed George Davies as president. Mr. Davies had been serving as general

sales agent for Davies and Thomas. Through the purchase of stock, Mr. Davies

gained control of the company in 1945. Between 1945 and 1947, the company

produced substantial tonnage of cast iron lining for the Battery to Brooklyn

tunnel. Shortly after this, operations were suspended and the Corporation was

liquidated. All physical assets were sold to the Schneider Associates of

Allentown, PA.

Davies

and Thomas Company became best known for its success in manufacturing tunnel

lining, as the company was a pioneer in the manufacture of iron plates for lining

tunnels under rivers by the shield method. Beginning in 1905, the company

supplied the cast‑iron segments for tubes for the under‑water

tunnels in New York City. Some of the prominent transportation projects in

which the Davies and Thomas product was used included the Holland Tunnel

(1923), the Lincoln Tunnel (1937), the Queens‑Midtown Tunnel (1936‑40),

and the Battery to Brooklyn Tunnel (1945). These were all vehicular tunnels.

Railroad tunnels included those for the Pennsylvania Railroad tunnels, the

Harlem River and the MacAdoo tunnels.

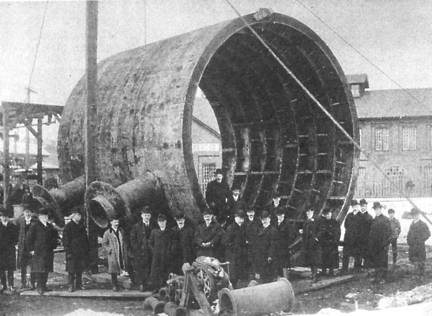

In

July 1904, it was reported in the Allentown, Pa. newspaper that the Davies and

Thomas Company had been awarded the largest contract for castings ever given to

a single firm. The Pennsylvania Railroad had decided to build an immense depot

in New York City and to tunnel beneath the North and the East Rivers. The

contract for the work at the East River was awarded to an English firm, J.

Pearson and Son. Four tubes, each more than a mile in length, would lie under the

river. The tubes were formed by cast‑iron segments, each 2 feet, 6 inches

wide and weighing 2300 pounds. Eleven segments formed one ring, 24 feet in

diameter. The contract required 108,000 tons of castings. A model of 8 rings,

20 feet long was made at the Davies and Thomas works for the Pennsylvania

Railroad and was later displayed at the St. Louis Exposition. At the time, C.R.

Horn was the general sales agent of the company and it was due to his efforts

that the contract was obtained.

Cast Iron tunnel segments from the Davies & Thomas Foundry “aging” on the hillside behind the Dery Silk Mill

In

1913, the newspaper again reported that Davies and Thomas had obtained a large

contract through the efforts of its agent, Mr. Horn. This contract was for the

manufacture of the lining of two large sewer tunnels for the Borough of Queens

on Long Island. Davies and Thomas was in competition for this contract with

eleven other firms including Bethlehem Steel. The news report noted that the

Davies and Thomas product was carefully made and that the plant was especially

well equipped for the work. "The segments are being faced in immense

planing mills and fitted together in circular lengths for the underground work,

being water tight and of sufficient strength to sustain great weight and

pressure."

Davies & Thomas workmen with a tunnel segment

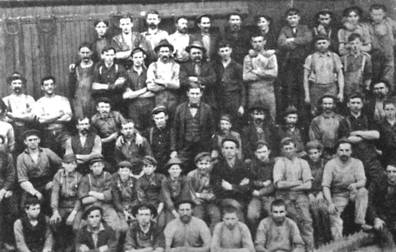

Workmen of the Davies & Thomas Foundry (Back row, 5th from left: Quincy Spengler, grandfather of Ruth Ellen Spengler Klinesinith)

The

story of Davies and Thomas does not end with its dissolution in 1947. A news

story date lined May 15, 1949 relates the following:

The

terrific explosion in New York's Holland Tunnel Friday provided a testimonial

to the former Davies‑Thomas Foundry in Catasauqua.

About

42,000 tons of steel segments produced at the Catasauqua plant went into the

construction of the tunnel in 1923. Although weakened, the tunnel failed to

crack when eighty drums of carbon disulfide, highly toxic and inflammable, on a

heavily laden chemical truck, exploded. Searching fireboats failed to find any

indications of a leak in the tunnel.

The

Davies‑Thomas Foundry contributed steel used in underground tunnels and

railroads in New York City, Philadelphia, Washington, and Baltimore. More than

eight per cent of the steel used in tunnels under New York harbor is the

product of this foundry.

Davies & Thomas executives pose before tunnel ring, circa 1904

Return to The Davies & Thomas Index

About The Hopkin Thomas Project